Laminated Zipper Bag

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 2000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

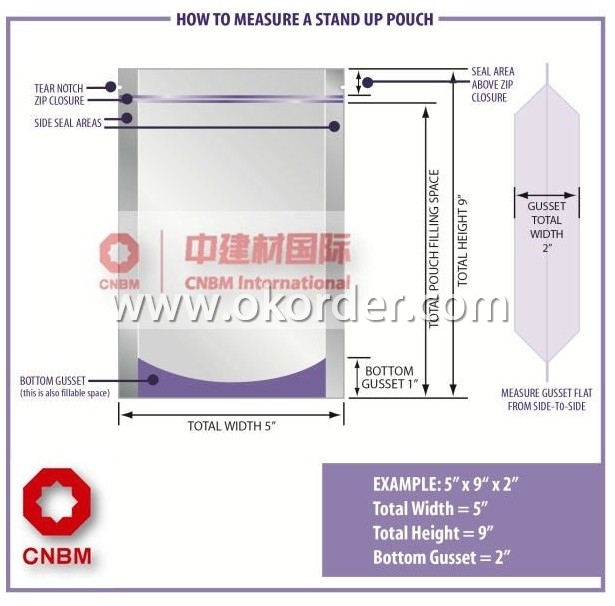

1. Specifications of Laminated Zipper Bag:

Excellent self-standing for maximum display and presentation

Can be opened repeatedly if zipper is added, convenient to use, easy to store and good air tightness.

Highly versatile, suitable for multiple applications.

Good resistance to pressure and drop, non-breakage and non-leakage.

Low storage and transportation cost.

Easy tear with V-cut or laser scoring.

Wide range of punch hole can be incorporated.

2. Usage of Laminated Zipper Bag:

Laminated Zipper Bagsare used for packing all kind of things like cometics, clothes, industry products etc.

3. Packaging & Delivery of Laminated Zipper Bag:

One 20GP container can be loaded about 10-15tons.

By sea or by air all available.

4. Production Flow of Laminated Zipper Bag:

1) the customer offers the artwork and we help design

2) confirmation for plates ordered

3) printing

4) laminating

5) separating and cutting

6) bag making

7) final inspection

8) shipping out

- Q:How about a carpenter's packing case?

- 1 plywood Plywood: plywood is made of wood, cut into sheets or wood squares, cut into thin wood, and then glued to three or more layers of three. Usually, the odd layer single plate is used, and the fiber direction of the adjacent layer single plate is mutually arranged vertically and glued. Therefore, there are three, five, seven, and so on odd layer plywood.Structurally, the outermost veneer of plywood is called a watch board, and the front panel is called a panel. It is made of the finest quality veneersMaterial. The reverse plate is called the backing plate, and the quality is the second sheet. The inner sheet is called the core plate or the middle plate, and it is made of the single sheet with the worst quality.2. What are the properties of plywood and what are they suitable for making?Each layer of the plywood is glued with glue, so its environmental protection is very poor. It is not recommended to be used in home decoration, if you want to say itWhat is suitable for making, then it is most suitable for making is the packing box.In addition, plywood is also suitable for concrete construction or scaffolding in construction sites.

- Q:What enterprises need wooden packing box?

- Material classification1. Wooden packing box: packing container made of wood and bamboo.2. No fumigation packing box: packing container made of composite material.3, strong safety: plastic packaging container for patent engineering plastics made by special technology.4, corrugated packaging box: it is through die cutting, indentation, nail box or sticky box made of corrugated cardboard boxes. Corrugated box is one of the most widely used packing products.

- Q:Is it necessary to leave the packing cases for large household appliances?

- Need to, under normal circumstances, when you purchase, sales will tell how long to keep. However, according to my personal experience, in the 7 day return, 15 days replacement during the three package, you must keep. If the return, the attachment is not complete, as businesses and factories, to charge a certain amount of discount fee, a paper box, how much money you do not sell, but for businesses and factories, which belongs to the machine accessories, in the non professional customer service outlets, is impossible to buy. When you get out, but also to return, is very troublesome.

- Q:How can the packing box be mounted onto the board?

- It can be used for packing of many kinds of goods, suitable for long distance transportation packaging with bad transportation conditions. Plywood thickness is 6mm, 9mm, 12mm and other specifications.

- Q:Can the express company provide the computer's packing box?

- When mailing an item, the courier company may provide a package service for the sender, but there is no requirementProvide the packaging with the goods needed by the sender.Solution: if you send a computer, you can communicate with the courier in advance,The package needed for the purchase of the package must be carried by the sender

- Q:Where do you use wood containers?

- Can use wood packing box where we live from and be too numerous to enumerate, various related supplies and food to the processing plant products, machinery and equipment to, more far, expensive crafts packaging will also use wood packing box, wood box to loading watches, pen, large loading cars, large machinery and equipment that should be used in packaging box.In the final analysis, as long as the goods are to be transported, they need to be packed; to better protect the contents of the box, consider the use of load-bearing properties, compression, impact resistance of wood packaging box. Careful, you can also find that the bottom of the container is also wood.I hope my answer will help you. If you don't feel clear enough, you can add questions, and I will always pay attention to your problems.

- Q:Is the packing box for express delivered by ourselves or by courier company?

- Express goods packaging boxes prepared by the customer himself, if you need to express delivery, you need to give certain fees: 1-5 yuanExpress packing box by the company unified order, its packaging box with the company logo, name, two-dimensional code, the official website and other related categoriesExpress package cost does not belong to mailing costs.Remarks: under normal circumstances, there are extra cartons for express outlets which are willing to offer to customers free of charge. If not provided, they are within the reasonable scope.

- Q:What are the requirements and procedures for exporting wooden packing boxes?!

- The export packing box is made of various kinds of wooden waste materials which are treated by high temperature and high pressure. The wooden box has high compressive resistance and Gao Chengzhong performance. Meanwhile, it avoids the defects of wooden knot, moth eaten, color difference and humidity in the traditional wooden case

- Q:What are the requirements for wooden packing boxes for exported goods?

- Outbound goods quarantine treatment of wood packaging management measures, in order to regulate the wood packaging and quarantine supervision and management, ensure the export goods use wood packaging quarantine requirements conform to the input country or region as mentioned in the present Measures wood packaging is used for carrying, packaging, bedding, support, reinforcement of goods wood materials, such as wooden box, wooden box, wooden pallets, wood frame, wooden, wood shaft, wedges, wooden pads, sleepers, wood etc..

- Q:Can the wooden packing box be transported by air directly? Or do you want to ship it in an air only container?

- Before the wood is packed, the wood needs to be fumigated before it can be transported by air. The same is true of shipping. The products packed in wood must be fumigated, and some countries are very sensitive to the transportation of wood. But the plywood doesn't need to be fumigated.

1. Manufacturer Overview |

|

|---|---|

| Location | Qindao, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Mid East, Northern Europe, Eastern Asia, Eastern Europe, Southeast Asia, Western Europe, Southern Europe |

| Company Certifications | ISO9001;BRC |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao, China |

| Export Percentage | 70%-80% |

| No.of Employees in Trade Department | 10-15 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Laminated Zipper Bag

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 2000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords