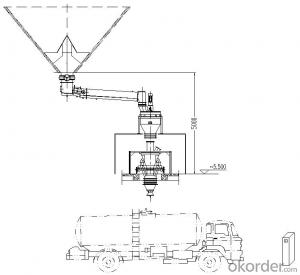

KXT (SZ) Cement Bulk Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portland KXT (SZ) cement bulk dosing and control system, for the first time to realize cement bulk and weigh integration in China. Powder business measurement technology is outshine domestic others.

1、 Product introduction

Since 1996, Portland carry out coriolis powder material measurement technology and related products production. With this company for cement production process, measuring principle, equipment design, automatic control method and other related professional comprehensive advantages, a batch of long engaged in cement production technology research of experts to pursuit technical progress, through efforts, we achieve success in the test method and signal processing scheme of key area of technology, successfully developed a new generation of large flow powder material measurement system - bulk cement measurement system that can be used in commercial measurement, realized the cement bulk and measurement integration, accuracy of measuring achieve plus or minus 0.5%.

The cement bulk metering system, can be used in bulk vehicle filling and loading quantity measurement, change the tradition that loading and measurement that is measured by the electronic platform scale is respective. The system also can be applied to cement bulk ship loading and quantity measurement.

2、Product features

“Cement bulk metering system" make bulk cement become simple and science, to solve the problem that there are many traditional ways,the efficiency is low, the human interference factors and so on.

"Cement bulk metering system" is a complete data processing and management system, including bulk process control, unit bulk quantity monitoring and display, bulk dynamic accumulative total, support data upload, etc.

"Cement bulk metering system" is not only used in one car is filled, but also used in finishing bulk process according to the requirements of the load.

"Cement bulk metering system" measures powder material flow by coriolis mechanics principle, and its accuracy is better than the plus or minus 0.5%. The measurement is accuracy, process is simple, layout is compact, convenient in maintenance, Accuracy of measuring, bulk and measurement rate, system reliability and other technical indexes is better than similar products.

"Cement bulk metering system" is also applied to railway, port, wharf, mining, metallurgy, chemical fertilizer, power, light industry etc powder and granular materials bulk measurement link, measuring ability ~ 800 m3 / h.

3, system function and technical features

——Realization of bulk cement continuous, uniformity and stability of feeding;

——To fill one car as the goal, accurate measurement for bulk cement loading quantity;

—— To quantitative loading as the goal, according to the setting loading quantity to quantitative accuracy control bulk cement loading.

—— To achieve the lower and upper limit alarm, data can be storage longly after power off, support data upload and instant printing function.

Measuring accuracy: ≤± 0.5%

—— Applicable material: moisture<3%, particle size 5mm

——Weighing range: 0~250t/h

——Use environment: temperature - 20 ℃ ~ 60 ℃, relative humidity 95% or less

4、service condition

since July 2010 ,"Cement bulk metering system" has saled 24 sets, the repercussions are good. The GUANDDONG QINGYUAN GUANGYING Cement co., LTD. has chosen 6 sets of KXT (SZ) - 250 cement bulk metering system, used in good condition.

- Q:What is the relevant content of the flow of materials, storage and usage

- Unitized packaging and standardization is the foundation of the enterprise logistics work, for the protection of the components, the follow-up of logistics planning and the determination of through put play a key role. Adopt the reasonable unitized equipment, can reduce the invalid labor (such as inversion, not fall to the ground) in the process of machining, improve labor efficiency, simplify the site management, reduce the security hidden danger. The idea of packaging unitization and standardization is controlled mainly from macro and micro level. On the macro level, we need to set the size chain for all materials from the perspective of the supply chain. From the tray to the turntable, the special frame should be coupled with this dimension chain. On the micro level. In order to meet the basic requirements of packaging design, such as the principle of protecting spare parts and saving space, choose the proper packaging materials, internal separation materials and so on. At the same time, the loading number of the packaging unit should be fixed so as to reduce the statistical workload of the on-site staff. Some factories have higher management requirements for packaging and line workstations, which require the packaging to be incorporated into the day-to-day management of the process. For packaging, cleaning, cleaning (cleaning oil, labeling, etc.), repair, storage, etc.

- Q:Talk about how to cut the cost of moving materials.

- Cost direct costs and indirect costs. Direct costs are inputs and manpower.I hope my answer will help you

- Q:There are three things to do when the material is stacked up and down

- In a cylinder, the side wall of a cylinder is fixed a few plates of iron (the width of a cylinder is a third of the cross section of the cylinder, non-contact like a paw), rolling the bottle, leaving the inlet and outlet

- Q:What is the proof of working in mechanical design?

- Don't waste your time in school textual research, the engineering drawing, mechanical principle, mechanical design, such as professional course learning, course design, graduation design with a good, better than nothing; Of course, there are some foreign investment that is required for the level 4, and there are exceptions. You design it well, and English doesn't matter.

- Q:The principle of material handling

- Adaptive principle (flexibility principle) : adopt methods and devices that can adapt to various kinds of work and applications, unless it is a device that must be used for a particular purpose. Reduce the principle of self-importance: reduce the ratio of air to heavy load. Principle of utilization: the optimal utilization rate of planning and carrying equipment and manpower. Maintenance principle: plan all the maintenance and maintenance of all moving equipment. Obsolete principle: replace outdated methods and equipment when there are more efficient means of handling and equipment. Control (control) principle: use material handling activities to improve control of production, inventory and order processing. The principle of production ability: use the handling equipment to improve the production capacity.

- Q:The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q:The material needs to be transported, it is easy to produce dust.

- We're doing the granule engineering, and we can talk about this: First: the properties of material itself, temperature, contact material, ability, distance and so on The second: the material that produces dust easily, the simplest principle is relatively close, ideal method is low speed of course. Third: as far as you are going to be able to transport it, you will have to sit down and discuss it

- Q:Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q:What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

- Q:What is the material handling and handling equipment?

- Lifting equipment Small lifting equipment | gantry crane | | bridge cantilever crane | 2 vertical mechanical unit transportation equipment | gravity conveyor power conveyor parts | | | other comprehensive transportation system

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

KXT (SZ) Cement Bulk Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords