ISO certificate decorative fabric wrapped fiberglass acoustic wall panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

CMAX

Ceiling Tile Shape:

Square

Ceiling Tile Type:

Fiberglass Ceilings

Product name:

fiberglass wall panelling for sale

Material:

Glass fiber

Standard size:

600*600 mm, 600*1200 mm, 600*1800 mm

Thickness:

12mm, 15mm, 20mm,25 mm

Advantage:

Heat/sound insulation, sound absorption, environmental protection

Application:

KTV, Hotel, Hanquet hall,Gymnasium, Multi-function

Packing:

15 PCS/CTN or as required

Certification:

ISO9001

MOQ:

100 sqm

Payment:

T/T, Trade assurance, L/C at sight,

Packaging & Delivery

Packaging Details

Packed in cartons for acoustic decorative fiberglass wall panelling for sale

Port

Shanghai, Qingdao,Lianyungang,Ningbo China

Lead Time :

15 days after deposit

Product Description

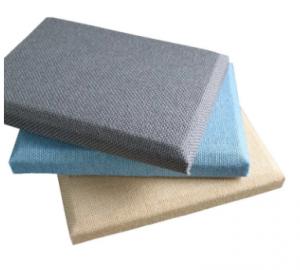

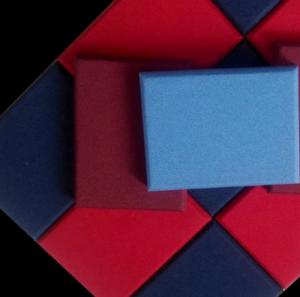

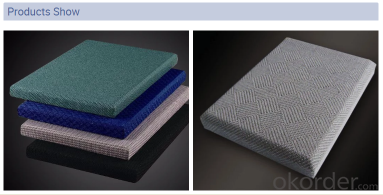

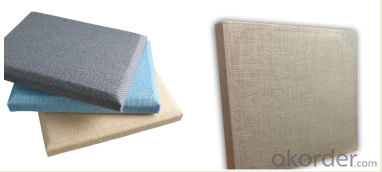

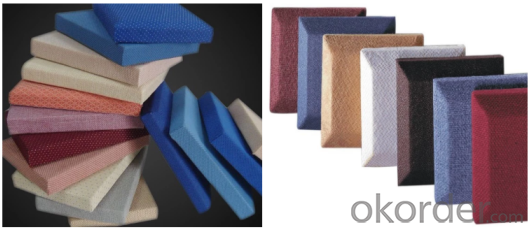

Acoustic Wall Panel Series

Soften space, constant temperature warm effect, the integration of decoration and whole frequency sound absorption. Optional colors and fabrics, meeting the varied acoustic and decorative requirement

Product Name | ISO certificate decorative fabric wrapped fiberglass acoustic wall panel |

Material | Glass fiber |

Frame | flame-retarded resin, wooden, aluminium |

Volume weight | ≥70~100 kg/m³ |

Fire performance | B1 |

Environmental performance | class E1 |

Thickness | 12 mm, 15 mm, 20 mm, 25 mm or 50 mm Customized |

Certification | ISO 9001, ISO 14000 |

Application | KTV, Hotel, Hanquet hall, Gymnasium, Multi-function room, Audio-video room, other acoustic required places |

Product features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

Packing & Delivery

Packing Details : Standard Package

Loading information for regular size:

Size | Thickness | Packing ( PCS /CTN ) | Quantity( 40 HQ ) |

600mm*600mm | 12 | 25 | 13300 PCS /532 CTNS /4788㎡ |

600 mm*1200mm | 12 | 25 | 6650 PCS /266 CTNS /4788㎡ |

600mm*600mm | 15 | 20 | 10640 PCS /532 CTNS /3830.4㎡ |

600 mm*1200mm | 15 | 20 | 5320 PCS /266 CTNS /3830.4㎡ |

600mm*600mm | 20 | 15 | 7980 PCS /532 CTNS /2872.8㎡ |

600 mm*1200mm | 20 | 15 | 3990 PCS /266 CTNS /2872.8㎡ |

600mm*600mm | 25 | 12 | 6384 PCS /532 CTNS /2298.2㎡ |

600 mm*1200mm | 25 | 12 | 3192 PCS /266 CTNS /2298.2㎡ |

- Q:The difference between GRC lightweight partition board and ceramic plate

- Hello, the difference between the two is great GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, , Non-combustible, sound insulation, can be sawed, drillable, can be nailed, can be shaved, can chisel, wall smooth construction Jane. Grc components are generally used in high-end villa exterior decoration or European-style building on the external walls of decoration. If the grc component of the type of large number of large Friends of the grc can be opened in the project next to a temporary plant to facilitate the construction of the late, grc components can be divided into color and gray.

- Q:Grc light partition board construction steps is what

- Partition board positioning, elastic line According to the construction drawings, in the installation of partition board, that is, the column side, ground, ceiling, beam bottom and the GRC light wall panels and other thickness of the two parallel ink line, and marked the door and window openings, Parallel to the side of the ink line 100mm pop up a parallel to the wall of the first three ink lines, as the inspection control line, after the installation of the partition to check the location of the partition is correct.

- Q:What is GRC and can I paint it?

- GRC is the abbreviation of Glass Fiber Reinforced Cement, which is a new type of composite material invented in the 1970s. It is made of alkali-resistant glass fiber as reinforcing material, sulphoaluminate low basicity cement as cemented material and mixed with suitable aggregate Substrate, by jetting. Mold casting. Squeeze out. Flow pulp and other processes made of new inorganic composite materials. The It combines light, high strength, high toughness and water resistance, non-combustion, sound insulation, heat insulation, corrosion resistance, easy processing and other characteristics set in one, occupies a unique position in the building. In recent years, China's GRC technology to a new stage of development. The GRC technology can produce Roman column, eaves line, waist line, door cover, window cover, top set, window side column, light partition board, transformer Such as flue, railing, garden relief, Tibetan components, antique components, mountain flowers, corridor, cultural stone and other hundreds of varieties, smooth and exquisite appearance of the components, pattern smooth realistic, stereotypes perfect, strong sense of art. The following are the same as the " 2, construction, easy installation, short duration. Production of various GRC prefabricated components, with cement affinity. Nine blogs J o? ~?] 5Z?]?]? L 3, GRC components light weight, high strength, good toughness, no cracking, no layer, water, non-combustible, and housing with the life. Spray on the paint, with the stone fought. 4, no "waste" pollution, is conducive to environmental protection. 5, loss. If there is a small amount of damage in the transport can also be installed after the completion of the decoration with cement, to ensure that the utilization of components 100%.

- Q:Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- With my experience I think FRP is better, long life, polyurethane foam and FRP is better, the price comparison is not clear, I only know that FRP: give you a unit price of 1.2 thick, 26 per square, 1.5 Thick ,,, 30 per square ;; Polyurethane foam unit price; 900 per cubic.

- Q:Glass fiber mesh quality soft and hard for the wall, which is better?

- The softness of the mesh cloth does not depend on the quality of the mesh cloth. Depending on how much glue is applied. Used in the wall, of course, is a lot of glue, and can increase the degree of alkali resistance. Now there is a kind of urine glue, painted out really hard But this is not alkaline.

- Q:What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced cement board: glass fiber reinforced cement board, glass fiber is used as a reinforcing material, plus cement, sand, water, admixture and other materials made of slats, which apply to ordinary or mid-range building grade. Glass fiber reinforced concrete (GRC-Glass Fiber Reinforced Cement) is a new type of composite material.

- Q:FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q:Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q:What is the difference between an ordinary partition board and a lightweight partition board?

- Light wall is a new type of energy-saving wall information, it is a kind of appearance like a hollow floor of the same wall material, but it has two male and female Falcon trough, the device only need to stand up, On a small number of mortar mortar after the assembly can be. It is composed of harmless phosphogypsum, light steel slag, fly ash and other industrial waste residue, by the frequency of steam pressure maintenance. Light wall panels with light weight, high strength, multiple environmental protection, thermal insulation, noise, breathing humidity, fire, rapid construction, down the cost of the wall and other advantages. The inner wall is equipped with reasonable layout of the insulation, sound absorption of inorganic foam profiles or other insulation materials, wall panels by the pipeline pouring, leveling, scientific maintenance, production of high degree of automation, the standard type.

- Q:What should the overall wardrobe design should have?

- 1, wardrobe side panels and laminates and other places need to bear the weight of 18mm thickness of the three polyamine in the density of fiberboard, the cabinet board to the national authority of the test report, in line with national mandatory standards GB18584-2001 standard, formaldehyde release The amount of ≤ 1.5mg / L, moisture content between 5-11; backplane does not require load-bearing, you can use 5mm thick to make, this can save costs, conditions permit, the door and backplane thickness should be 9mm. For the hanging cabinet, the back plate on the need to use 18mm thickness, density standard 0.6-0.9g / cm3, to enhance the stability of the hanging cabinet; ???? 2, although the overall wardrobe is tailor-made products, but there are standard and non-standard points, the standard parts is the manufacturer in accordance with the specifications of the plate to calculate the production, you can achieve maximum use of the board, the edge is generally uniform, Black line and sawtooth printed; non-standard parts will waste a lot of sheet metal, so the price, non-price will be more expensive;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ISO certificate decorative fabric wrapped fiberglass acoustic wall panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products