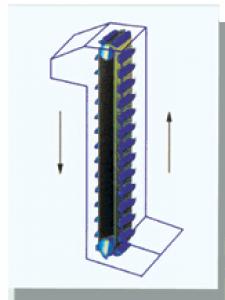

Industrial Rubber Conveyor Belting Pulleys Anti Static With 3mm - 8mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyurethane round belt are available with orange color smooth surface and green color rough surfaces and reinforced nylon, fibers, Kevlar and steel card .It also can jointed belt to o-ring. The diameter range from 2mm-20mm,we have professional worker can help you to jointed belt.

In addition, we also can supply a set of the connecting tools &accessories to you, it’s include to clamp, the electric ion and knife, connecting methods is butt joint and overlap joint.

Product Details:

Color:Green

Hardness:85A-90A

Surface:Rough

Type:PU Rough Round Belt

Lead Time:5days-7days

Model Number:diameter3-20m

Industrial Rubber Conveyor Belting Pulleys Anti Static With 3mm - 8mm

polyurethane Round Belts Feature:

1. With excellent bend resistant

2. abrasion/wear resistant

3. easily connected

4. it's not easy to be broken at low temperature

5. fuel and oil resistant

6. anti static

polyurethane round belt Application :

1. Widely used in textile

2. printing and packing machine

3. food & beverage processing

4. wood processing

5. paper processing

6. electronic

7. post service

8. tobacco transmission line

9. Wall floor tile conveying industrial line

10. Ceramic industry line or polishing line

| Items No. φ | least radius of gyration | stretch rate | Maximum tensile rate | Hardness | length of rolled | ||

Dia. (mm) | In | mm | Stretching rate | Kg | Lbs | Hardness (A) | Roll (m) |

| 2 | 0.79 | 20 | 1.5-3% | 0.3 | 0.7 | 90A | 400 |

| 3 | 0.98 | 25 | 1.5-3% | 0.7 | 1.6 | 90A | 400 |

| 4 | 1.38 | 35 | 1.5-3% | 1.2 | 2.7 | 85A | 200 |

| 15 | 4.72 | 120 | 1.5-3% | 17.7 | 39.0 | 85A | 30 |

| 18 | 5.71 | 145 | 1.5-3% | 25.4 | 56.0 | 85A | 30 |

| 20 | 6.30 | 160 | 1.5-3% | 31.3 | 69.0 | 85A | 30 |

FAQ

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q:What's the difference between a rubber belt and a polyurethane belt?

- The strength and elasticity of rubber are betterPolyurethane is more flexible and less prone to deformation! The weight is comparatively lightThe plant's line is good with polyurethane!If it is a mine or coal or similar mineral, use rubber as a good point

- Q:How do you remove the gasoline from the rubber band?

- The official name is thinner, thinner or solvent oil, usually colorless transparent liquid, commonly known as banana water.

- Q:What sectors does rubber drive? That is to say, what are the main uses of rubber?

- Cars, railways, shoes, wires, cables, new materials, many

- Q:How to clean rubber band?

- 1. Soak it in hot water for a while, then you can peel it off.2, use the hair dryer blow, the glue baking heat can be got down.3, with Fengyoujing rub, then try out.4, you can try a rubber. But in the beginning, you may think the more you rub the dirt, but the longer the rub, you will see the effect, this method is relatively tired, have perseverance.5, with blisters, put a little detergent, and then use an old toothbrush to brush.6, with a cloth with alcohol or Erguotou wipe it.

- Q:Conveyor rubber belt welding

- The belt of belt conveyor consists of reinforcing material (core), core material (adhesive), covering rubber and adhesive. Delivery method with connection mechanical connection method, cold glue connection method, heat curing connection method three kinds, including mechanical connection and cold glue connection method is only applicable to fabric conveyor belt, heat curing connection method is suitable for all kinds of rubber conveyor belt.

- Q:JSP what does water swelling rubber belt mean?

- Water swellable rubber sealing strip is imported with special rubber as the main raw material, with a rubber strip products of inorganic absorbent, high viscosity resin and so on more than ten kinds of special material by mixing, mixing, extrusion and the.

- Q:What's the rubber band on your wrist when you play basketball?

- It means the player's message strip, usually with the name of the player, the team and the number, but we are not professional players, so take that as a decoration

- Q:90 degree turn conveyor

- Hello, general conveyor belt conveyor belt, roller, roller and drive, brake, tension, modification, loading, unloading, cleaning and other devices.

- Q:The difference between roller printing machine and rotary screen printing machine

- Round screen printing is a kind of printing method that uses the scraper to print the paste in the circle net under pressure. There are several important aspects of rotary screen printing, which are different from other screen printing methods. Rotary screen printing and printing roller, Department of continuous process, printing fabric by wide rubber band is transported to the continuous movement of the rotary cylinder. The principle and the roller opposite to its, is in the round net (nickel net) as internal extravasation (by scraper, bar and slurry pressure) to complete printing;

- Q:White rubber strap dirty, how to do?

- First, fold the film and magazine together, then roll them together into a cylinder, which prevents the book from wetting the strap while cleaning the strap.Then put the watch on the roll of the cylinder. Zoom in on the magazine roll until the watch band is fully extended and the watch won't fall off. In this way, on the one hand, it is convenient for cleaning in a while, and more importantly, after opening the watchband, the stains at the slit of the watchband can be cleaned.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Rubber Conveyor Belting Pulleys Anti Static With 3mm - 8mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords