Hot Selling Deformed Reinforcing Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

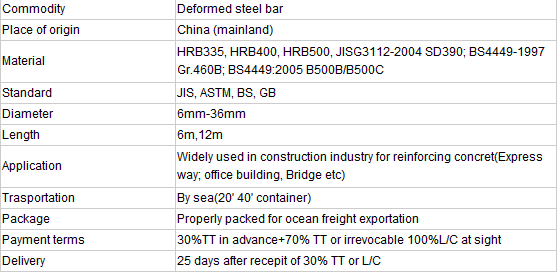

Specifications

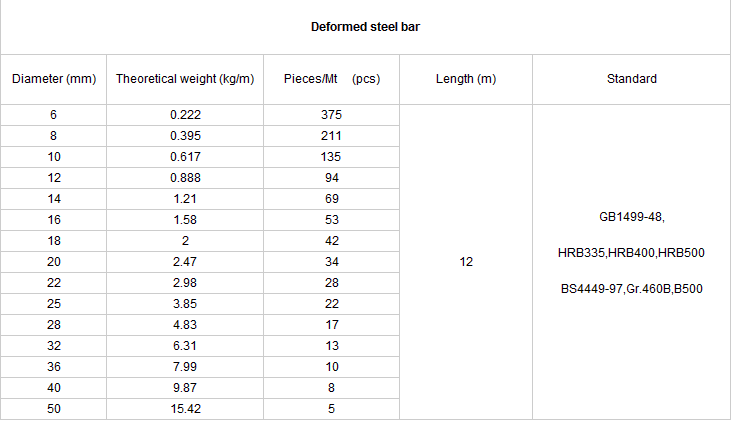

Grade HRB335-2007 HRB400-2007 HRB500-2007

Quenched or microalloyed

DIA 12.0mm~40.0mm deformed bar

STEEL REBARS

GB1499 Grade HRB335-2007 ( quenched or microalloyed)

GB1499 Grade HRB400-2007 (quenched or microalloyed)

GB1499 Grade HRB500-2007 ( microalloyed 20MnSiNb and 20MnSiTi)

Cutting to length: 9 or 12 1500-5000(KG) (Max.500kg/m)

Cutting to length: 6 or 7 or 8 1500-4000(KG) (Max.500kg/m)

- Q:How can the quality of steel rebars be tested?

- To ensure the strength and reliability of steel rebars, there are various methods available for testing their quality. Some commonly used techniques include: 1. Conducting a visual inspection to identify any visible defects like surface cracks, unevenness, or corrosion that may impact performance. 2. Analyzing the chemical composition of the rebars through spectroscopy or similar methods to ensure compliance with required standards. This analysis verifies the presence and percentage of elements such as carbon, manganese, and silicon. 3. Testing the rebars' tensile strength by subjecting a sample to tension until it fractures. The maximum force applied before breaking determines the tensile strength and helps identify weak spots or inconsistencies. 4. Evaluating the ductility of rebars through a bend test, bending them to a specific angle without any signs of cracking or fracture. This ensures the rebars can withstand bending and shaping during construction without compromising their structural integrity. 5. Using ultrasonic testing to detect internal flaws or defects within the rebars. This non-destructive method helps identify hidden cracks, voids, or inclusions that could weaken the rebars. 6. Determining the hardness of the rebars using the Rockwell or Brinell hardness test. This test measures the resistance of the rebar's surface to indentation, providing insight into its strength. 7. Subjecting the rebars to corrosion resistance testing, such as salt spray testing or electrochemical methods, to assess their resistance against rust and other types of corrosion. By combining these testing methods, manufacturers, construction companies, and engineers can ensure that steel rebars meet the required quality standards and can withstand the intended load and environmental conditions.

- Q:Are there any standards for the spacing of steel rebars in concrete?

- Steel rebars in concrete have specific spacing standards in place to guarantee the durability and structural integrity of the reinforced concrete. These standards may vary depending on factors such as the type of structure, load conditions, and local building codes. In the United States, the American Concrete Institute (ACI) provides guidelines for rebar spacing in their publication ACI 318, known as "Building Code Requirements for Structural Concrete." According to ACI 318, the minimum spacing between parallel reinforcing bars should be equal to or greater than the maximum bar size or 1.5 times the diameter of the largest coarse aggregate used in the concrete, whichever is larger. For instance, if the maximum bar size is 12mm and the largest coarse aggregate size is 20mm, the minimum spacing between the rebars should be 30mm (1.5 times the largest aggregate size). This ensures sufficient concrete cover around each rebar, protecting it from corrosion and providing adequate bond strength. In addition to the minimum spacing, ACI 318 also offers guidelines for the maximum spacing of rebars. These guidelines take into account factors such as the size and shape of the concrete member, the type of loading it will experience, and the required strength. The maximum spacing is typically determined to prevent excessive cracking and ensure proper distribution of loads throughout the structure. It is important to note that local building codes and regulations may have additional requirements or deviations from the ACI standards. Therefore, it is always recommended to consult the relevant building codes or work with a qualified structural engineer to ensure compliance with the specific spacing requirements for steel rebars in concrete in your area.

- Q:How do steel rebars affect the overall vibration resistance of a structure?

- Steel rebars can significantly enhance the overall vibration resistance of a structure. Rebars, also known as reinforcement bars, are typically made of high-strength steel and are commonly used in reinforced concrete structures. The primary role of rebars is to provide tensile strength to the concrete, which is otherwise weak in tension. By embedding the rebars within the concrete, they effectively resist the tensile forces that may arise due to applied loads or vibrations. Steel rebars help to distribute the stress and strain throughout the structure, preventing localized failure points and increasing the overall structural integrity. In the case of vibrations, rebars act as a damping mechanism, absorbing and dissipating the vibrational energy. This damping effect reduces the amplitude and frequency of vibrations, thereby increasing the structure's resistance to vibration-induced damage. Moreover, the presence of rebars also improves the dynamic properties of the structure, such as its natural frequency and mode shapes. This is particularly important in structures such as bridges, tall buildings, or industrial facilities, where vibrations can be induced by external factors like wind, seismic events, or machinery operations. In summary, steel rebars enhance the overall vibration resistance of a structure by providing additional strength, distributing stress, and acting as a damping mechanism. Their presence improves the structural integrity, reduces the risk of failure, and ensures the safety and longevity of the construction.

- Q:What is the difference between mild steel rebars and high-strength steel rebars?

- Mild steel rebars and high-strength steel rebars are two different types of reinforcement bars used in construction. The key difference between these two lies in their composition and mechanical properties. Mild steel rebars, also known as low carbon steel rebars, are made from steel with a relatively low carbon content. Typically, they have a carbon content of about 0.15% to 0.30%. These rebars are commonly used in general construction projects where the concrete structure does not require high tensile strength. Mild steel rebars have a relatively lower yield strength and ultimate tensile strength compared to high-strength steel rebars. On the other hand, high-strength steel rebars, also known as high tensile strength rebars or HSD bars, are made from steel with a higher carbon content, typically ranging from 0.40% to 0.60%. These rebars are specially designed to provide superior strength, durability, and load-bearing capacity. High-strength steel rebars have a significantly higher yield strength and ultimate tensile strength compared to mild steel rebars. This makes them suitable for use in critical structures that require a high load-bearing capacity, such as bridges, high-rise buildings, and industrial structures. Another important difference between mild steel rebars and high-strength steel rebars is their ductility. Mild steel rebars have better ductility, meaning they can undergo more deformation before failing. This property allows mild steel rebars to absorb more energy during an earthquake or other dynamic loads, making them suitable for seismic zones. High-strength steel rebars, on the other hand, have lower ductility but higher stiffness and strength, making them more resistant to extreme loads and providing better structural integrity. It is important to note that while high-strength steel rebars offer superior strength and load-bearing capacity, they are also more expensive compared to mild steel rebars. Therefore, the choice between these two types of rebars depends on the specific requirements of the construction project, including the structural design, load conditions, and budget constraints.

- Q:12 how much is one ton of thread steel?

- If it is hrb400e three grade rebar, then 12 of the meter price is 2.07 yuan; if it is hrb50 four grade rebar, that 12 of a meter price of 2.23 yuan.

- Q:What are the recommended practices for welding steel rebars?

- To achieve a strong and reliable bond when welding steel rebars, certain recommended practices should be followed. These practices encompass: 1. Cleanliness: Prior to welding, it is crucial to ensure that the surfaces of the rebars are clean and devoid of any contaminants such as dirt, rust, or grease. Wire brushing or sandblasting can be employed to achieve a thorough cleaning. 2. Preheating: Preheating the steel rebars before welding can minimize the risk of cracking and enhance the weld's quality. The preheating temperature should be determined based on the rebar's thickness and the specific welding procedure being used. 3. Welding process: There are various welding processes suitable for steel rebars, with shielded metal arc welding (SMAW) and gas metal arc welding (GMAW) being the most commonly used. The choice of process is influenced by factors like rebar size, project requirements, and local regulations. 4. Electrodes and filler material: It is crucial to select electrodes and filler materials that are suitable for achieving a strong and durable weld. It is recommended to use materials that match the rebar's carbon content and strength. 5. Welding technique: Employing proper welding techniques, such as maintaining a consistent arc length, controlling the travel speed, and ensuring proper joint alignment, is essential for producing high-quality welds. 6. Post-weld treatment: After welding, it is important to allow the welded rebars to cool gradually to prevent thermal stress. Performing post-weld treatments, such as stress relieving, can also help minimize residual stresses and improve the weld's integrity. 7. Inspection and testing: Regular visual inspections and non-destructive testing, such as ultrasonic or magnetic particle testing, should be conducted to ensure the quality and integrity of the welded rebar joints. 8. Compliance with codes and standards: It is vital to always adhere to the relevant welding codes and standards specified by local authorities or project requirements. Compliance ensures that the welding process and quality meet the necessary specifications and safety guidelines. It should be noted that welding steel rebars should only be performed by trained and qualified personnel who possess extensive knowledge of welding techniques and safety practices. By following these recommended practices, the strength, durability, and safety of steel rebar welds can be ensured.

- Q:What are the advantages of using composite steel rebars?

- There are several advantages of using composite steel rebars. Firstly, composite steel rebars offer higher tensile strength compared to traditional steel rebars, making them more durable and resistant to deformation. Secondly, they have a lower coefficient of thermal expansion, reducing the risk of cracking and improving long-term performance. Additionally, composite steel rebars are corrosion-resistant, ensuring a longer lifespan and lower maintenance costs. Furthermore, these rebars are lighter in weight, making them easier to handle and transport. Lastly, composite steel rebars can be easily fabricated and installed, allowing for greater design flexibility and faster construction.

- Q:Are steel rebars suitable for use in industrial facilities?

- Yes, steel rebars are suitable for use in industrial facilities. They provide excellent strength and durability, making them ideal for reinforcing concrete structures in such facilities. Steel rebars can withstand heavy loads and extreme conditions, ensuring the safety and long-term stability of industrial buildings and infrastructure.

- Q:Are steel rebars susceptible to creep deformation?

- Yes, steel rebars are susceptible to creep deformation.

- Q:What is the importance of proper anchoring of steel rebars in concrete?

- The proper anchoring of steel rebars in concrete is crucial for ensuring the structural integrity and stability of the concrete structure. When rebars are not properly anchored, they may become loose or detached from the concrete, leading to potential structural failure, especially under heavy loads or seismic activity. Proper anchoring helps to distribute stress and load evenly throughout the concrete, preventing cracks, displacement, and collapse. It also enhances the bond between the steel and concrete, improving the overall strength and durability of the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Selling Deformed Reinforcing Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords