Hot Rolled Steel Equal Angle Bar Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

.

Product Advantages:

OKorder's Angle Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

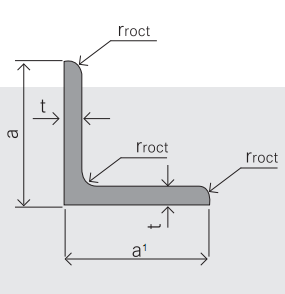

3. Sizes

4. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Packaging & Delivery of Equal Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:Can steel angles be used for framing in modular homes?

- Yes, steel angles can be used for framing in modular homes. Steel angles provide structural support and stability, making them an ideal choice for framing in modular homes. They are durable, versatile, and can withstand the various loads and forces associated with modular home construction.

- Q:What is the minimum radius for a curved steel angle beam?

- The minimum radius for a curved steel angle beam depends on various factors such as the size and thickness of the angle beam, the type of steel used, and the specific application requirements. It is recommended to consult structural engineers or refer to relevant design codes and standards for the specific project to determine the appropriate minimum radius for a curved steel angle beam.

- Q:What are the different types of steel angle connections used in seismic design?

- There are several types of steel angle connections commonly used in seismic design, including bolted angle connections, welded angle connections, and moment-resisting angle connections. Bolted angle connections involve connecting angles together using bolts, providing flexibility and ease of installation. Welded angle connections involve welding the angles together, creating a strong and rigid connection. Moment-resisting angle connections are designed to resist bending moments and provide enhanced resistance against seismic forces. These connections typically combine elements of both bolted and welded connections to achieve optimal strength and flexibility.

- Q:How do you prevent buckling of steel angles under compressive loads?

- To prevent buckling of steel angles under compressive loads, several measures can be taken. Firstly, increasing the thickness of the angle can enhance its resistance to buckling. Additionally, reinforcing the angle with stiffeners or gussets can provide added stability. Proper bracing and support during installation can also help prevent buckling. Finally, considering the design and load distribution in the structure can aid in preventing excessive compressive forces on the steel angles.

- Q:What are the considerations for selecting the appropriate steel angle thickness?

- When considering the appropriate thickness for a steel angle, there are multiple factors to take into account. Firstly, the project's structural requirements are of utmost importance. This includes assessing the load-bearing capacity, support requirements, and adherence to specific design codes or standards. The chosen steel angle thickness should guarantee the structural integrity of the project. The application of the steel angle also plays a crucial role in determining the suitable thickness. Different applications have varying demands in terms of strength, durability, and resistance to environmental factors. For instance, if the steel angle will be used in a corrosive environment, a thicker thickness may be necessary to provide enhanced protection against corrosion. Cost-effectiveness is always a significant consideration in construction projects. While thicker steel angles may offer greater strength and stability, they can also be more expensive. Striking a balance between the required strength and the available budget is essential for ensuring cost-effectiveness. Furthermore, the selected steel angle thickness should align with the manufacturing and fabrication capabilities of the manufacturer. It is important to consider the availability of the desired thickness and the feasibility of producing the required dimensions. In some cases, the appearance of the steel angle may also be a factor to consider. Thicker angles can have a more substantial and visually appealing look, which can be desirable in certain architectural or design applications. The availability of steel angles in different thicknesses and standard sizes can also influence the selection process. Opting for a thickness that is readily available in the market is often more convenient and cost-effective. To conclude, selecting the appropriate steel angle thickness involves careful consideration of structural requirements, application demands, cost-effectiveness, manufacturing limitations, aesthetic preferences, and the availability of standard sizes. By taking all these factors into account, an informed decision can be made to meet the project's needs and ensure the desired level of strength and durability.

- Q:Can steel angles be used for bracing purposes?

- Yes, steel angles can be used for bracing purposes. Steel angles are commonly used as structural components in construction due to their strength and durability. They are often used to provide additional support and stability to various structures, including buildings, bridges, and industrial equipment. Steel angles can be easily bolted or welded to the main framework of a structure, providing additional rigidity and resisting forces such as compression, tension, and lateral loads. Their versatile shape allows for a wide range of bracing applications, making them a popular choice for bracing purposes in construction and engineering projects.

- Q:What are the different corrosion protection methods for steel angles?

- There exists a range of corrosion protection methods for steel angles, which depend on the particular application and environmental conditions. Some commonly employed methods are as follows: 1. Galvanization: Coating the steel angles with a layer of zinc is a highly effective method of corrosion protection. The zinc layer acts as a sacrificial anode, corroding in place of the underlying steel. 2. Paint coatings: The application of a high-quality paint coating to the steel angles offers effective corrosion protection. The paint acts as a barrier, preventing moisture and corrosive substances from reaching the steel surface. 3. Powder coating: Similar to paint coatings, powder coating involves the application of a dry powder to the steel angles, followed by baking to create a durable and corrosion-resistant finish. 4. Epoxy coatings: For steel angles exposed to harsh environments or aggressive chemicals, epoxy coatings are commonly used. These coatings exhibit excellent adhesion and corrosion resistance. 5. Cathodic protection: This method involves the utilization of a sacrificial anode or impressed current to safeguard the steel angles from corrosion. The anode corrodes instead of the steel, providing long-lasting protection. 6. Barrier coatings: Barrier coatings, such as polyethylene or PVC wraps, create a physical barrier between the steel angles and the surrounding environment. This prevents moisture and corrosive substances from reaching the surface. 7. Hot-dip galvanizing: In this method, the steel angles are immersed in a bath of molten zinc, resulting in the formation of a thick zinc coating that offers superb corrosion protection. When selecting a corrosion protection method for steel angles, it is vital to consider the specific requirements of the application. Factors such as the environment, expected service life, and budget must be taken into account to ensure the most suitable method is chosen.

- Q:What is the maximum temperature that steel angles can withstand?

- The maximum temperature that steel angles can withstand depends on the grade of steel used. Generally, low carbon steel angles can withstand temperatures up to 600-700 degrees Celsius (1112-1292 degrees Fahrenheit) before their mechanical properties begin to deteriorate. However, higher carbon steels, stainless steels, or alloy steels can withstand higher temperatures, ranging from 800-1200 degrees Celsius (1472-2192 degrees Fahrenheit) or even higher. It is important to consult the specific material specifications or consult with a materials engineer to determine the maximum temperature a particular steel angle can withstand in a specific application.

- Q:Can steel angles be used for stairs or handrails?

- Indeed, stairs or handrails can make use of steel angles. In construction, steel angles are frequently employed due to their ability to offer structural support and stability. In the case of stairs, steel angles can be integrated as stringers or supports, guaranteeing the staircase's stability and strength. Similarly, for handrails, steel angles can be utilized as the primary frame or support structure, ensuring a robust and secure handrail for users. The incorporation of steel angles in stairs and handrails presents advantages such as durability, resistance to deterioration, and the capacity to withstand heavy loads, which contribute to their popularity in construction endeavors.

- Q:Can steel angles be used for scaffolding?

- Yes, steel angles can be used for scaffolding. They are commonly used as structural components due to their strength, stability, and durability. Steel angles provide a stable and secure platform for workers to access higher areas during construction or maintenance activities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Equal Angle Bar Different Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords