HOT ROLLED STEEL ANGLE BAR EAL QUAL ANGLE BAR Q235 JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

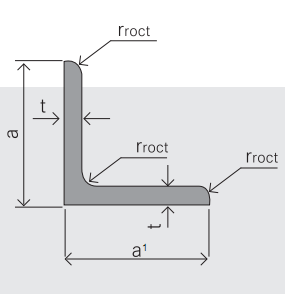

Specifications of Structure Steel Angle Bar

1.Invoicing on theoretical weight or actual weight as customer request

2.Standards:GB,ASTM,BS,AISI,DIN,JIS3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Structure Steel Angle Bar

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

- Q:Can steel angles be used in load-bearing columns?

- Yes, steel angles can be used in load-bearing columns. Steel angles are often used in construction for their strength and durability. They provide structural support and can be used to reinforce load-bearing columns. The angle shape of the steel allows for greater stability and load-bearing capacity compared to other materials. Steel angles are commonly used in the construction of buildings, bridges, and other structures where load-bearing columns are required.

- Q:What is the minimum thickness for a steel angle?

- The minimum thickness for a steel angle typically depends on the specific application and the load it needs to bear. However, in general, steel angles are available in various thicknesses ranging from 1/8 inch to 1 inch or more.

- Q:How do you prevent steel angles from bending under load?

- To prevent steel angles from bending under load, there are a few key measures that can be taken: 1. Select the appropriate angle size and material: Ensure that the steel angle chosen is of an adequate size and material strength to withstand the expected load. Consult structural engineering guidelines or professionals to determine the right dimensions and material composition for the specific application. 2. Reinforce the angle: Strengthen the steel angle by adding additional support or reinforcement. This can be achieved through techniques such as welding additional plates to the angle, using gussets or stiffeners, or adding diagonal bracing. These reinforcements help distribute the load more evenly and reduce the risk of bending. 3. Increase the thickness: If possible, increasing the thickness of the steel angle can enhance its load-bearing capacity. A thicker angle will have greater resistance to bending and deformation under load. 4. Proper installation: Ensure that the steel angles are installed correctly and securely to maximize their ability to resist bending. This includes using appropriate fasteners, such as bolts or welds, and following proper installation techniques. 5. Avoid excessive loads: Preventing steel angles from bending under load also involves careful consideration of the maximum load that they will be subjected to. Avoid overloading the angles beyond their design capacity, as this can significantly increase the risk of bending or failure. 6. Regular inspections: Regularly inspect the steel angles for any signs of bending, cracking, or deformation. Timely identification of any potential issues allows for prompt maintenance or reinforcement, preventing further damage or accidents. It is crucial to consult with a qualified structural engineer or professional experienced in steel fabrication to ensure proper design and implementation of these measures to prevent steel angles from bending under load.

- Q:Can steel angles be used in conveyor systems or material handling equipment?

- Yes, steel angles can be used in conveyor systems or material handling equipment. They provide structural support and stability, making them suitable for constructing frames and supports in conveyor systems and material handling equipment.

- Q:How do you calculate the weight of a steel angle?

- In order to determine the weight of a steel angle, one must have knowledge of its dimensions and the density of steel. The weight of an object can be determined by using the equation: Weight = Volume × Density For a steel angle, the volume can be obtained by multiplying the cross-sectional area of the angle by its length. The cross-sectional area of the angle can be calculated by multiplying its width by its height. Once the volume is determined, it can be multiplied by the density of steel to find the weight. Let's consider an example where a steel angle has a width of 3 inches, a height of 3 inches, and a length of 6 feet. The density of steel is typically around 7850 kg/m³ or 0.2836 lb/in³. To begin, calculate the cross-sectional area: Area = width × height Area = 3 in × 3 in Area = 9 in² Next, compute the volume: Volume = Area × length Volume = 9 in² × 6 ft × 12 in/ft Volume = 648 in³ Finally, determine the weight: Weight = Volume × Density Weight = 648 in³ × 0.2836 lb/in³ Weight = 183.9828 lb Hence, the weight of the steel angle would be approximately 183.98 pounds.

- Q:Can steel angles be used for pedestrian bridges or walkways?

- Yes, steel angles can be used for pedestrian bridges or walkways. Steel angles provide strength, stability, and durability, making them suitable for supporting the weight of pedestrians and ensuring the safety of the structure.

- Q:What is the typical ductility of steel angles?

- The typical ductility of steel angles can vary depending on the specific grade and composition of the steel. However, in general, steel angles have good ductility due to the inherent properties of steel, which allows them to be easily bent or deformed without breaking.

- Q:Can steel angles be used for agricultural buildings or barns?

- Yes, steel angles can be used for agricultural buildings or barns. Steel angles are commonly used in construction due to their strength and durability. They are particularly useful in agricultural buildings or barns where the structure needs to withstand heavy loads and harsh weather conditions. Steel angles can be used for framing, bracing, and reinforcing various components of the building, such as walls, roofs, and doors. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them a versatile choice for agricultural buildings or barns.

- Q:How do steel angles contribute to the overall strength of a structure?

- Steel angles contribute to the overall strength of a structure in several ways. First and foremost, they provide structural stability by distributing the load and forces evenly throughout the structure. The L-shape of steel angles allows them to resist bending and twisting, making them ideal for providing support and preventing deformation. Steel angles are often used as bracing elements in construction due to their high strength-to-weight ratio. By adding diagonal steel angles to a structure, it becomes more resistant to lateral forces such as wind or seismic loads. These angles help to transfer the applied forces to the foundation, reducing the risk of structural failure. Another way steel angles contribute to strength is by providing additional reinforcement. They can be strategically placed at critical points of a structure, such as corners or joints, to enhance its overall rigidity and durability. Steel angles can also be used as framing members, supporting beams, or columns, further enhancing the load-bearing capacity of the structure. Moreover, steel angles are resistant to corrosion and have a long lifespan, making them a reliable choice for structural applications. They can withstand harsh environmental conditions, ensuring the structural integrity of the building over time. Overall, steel angles play a crucial role in enhancing the strength and stability of a structure. Their ability to distribute loads, resist bending and twisting, provide reinforcement, and withstand environmental factors make them an essential component in modern construction.

- Q:How do you determine the axial capacity of a steel angle?

- In order to ascertain the axial capacity of a steel angle, one must consider several factors. First and foremost, it is crucial to determine the yield strength of the steel angle. Typically, this information is provided by the manufacturer and can be found in material specifications. The yield strength denotes the maximum stress that the steel angle can endure without experiencing permanent deformation. Following that, the cross-sectional area of the steel angle must be computed. This can be achieved by measuring the angle's dimensions, such as the thickness and the length of its legs. The cross-sectional area is then obtained by multiplying the thickness by the sum of the two leg lengths. Once the cross-sectional area is ascertained, the axial capacity can be calculated by multiplying the yield strength by the cross-sectional area. This will determine the maximum load that the steel angle can bear in a purely axial direction without failure. It is important to bear in mind that there are additional factors that can impact the axial capacity of a steel angle, including the presence of holes or notches, the slenderness ratio, and the loading conditions. Therefore, it is advisable to consult relevant design codes, standards, or engineering handbooks for more comprehensive guidance and to account for these supplementary factors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HOT ROLLED STEEL ANGLE BAR EAL QUAL ANGLE BAR Q235 JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords