Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

Details of Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

Name | Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

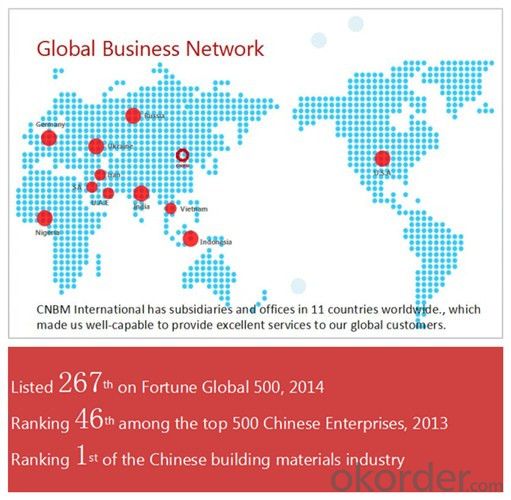

CNBM Introduction of Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar Supplier

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the applications of special steel in the nuclear supply chain?

- Special steel is widely used in the nuclear supply chain due to its unique properties. It is primarily utilized in various applications such as reactor vessel fabrication, fuel assembly manufacturing, and construction of critical components in nuclear power plants. The exceptional strength, durability, and resistance to corrosion of special steel ensure the safe and reliable operation of nuclear facilities. Additionally, special steel is also employed in the production of storage casks for nuclear waste, as it provides the necessary structural integrity and protection against radiation. Overall, the applications of special steel in the nuclear supply chain are crucial for maintaining the integrity and safety of nuclear power generation.

- Q:How is special steel used in the production of consumer goods?

- Special steel is used in the production of consumer goods due to its superior strength, durability, and corrosion resistance. It is commonly used in manufacturing appliances, cutlery, automotive components, and construction materials, ensuring the end-products meet high-quality standards and have a longer lifespan.

- Q:What are the different surface treatments used for special steel?

- There are several surface treatments commonly used for special steel, including galvanization, nitriding, carburizing, and plating. Galvanization involves applying a protective zinc coating to prevent corrosion. Nitriding is a heat treatment process that enriches the surface of the steel with nitrogen, enhancing hardness and wear resistance. Carburizing involves introducing carbon into the steel's surface, creating a hardened layer. Plating, on the other hand, involves covering the steel with a thin layer of another metal, such as chrome or nickel, for improved aesthetics and corrosion resistance.

- Q:What is the impact strength of special steel?

- The impact strength of special steel is high, making it resistant to fractures or breaking under high impact or sudden forces.

- Q:How does special steel contribute to improving product performance in corrosive environments?

- Special steel contributes to improving product performance in corrosive environments by offering enhanced resistance against corrosion. The unique composition of special steel, which includes elements such as chromium, nickel, and molybdenum, provides a protective layer that prevents the material from being affected by corrosive elements present in the environment. This resistance to corrosion ensures that the product remains durable, reliable, and unaffected by rust or degradation, ultimately enhancing its performance and longevity in corrosive conditions.

- Q:Can special steel be used in mining applications?

- Indeed, mining applications can utilize special steel. This unique material, also known as alloy steel, features enhanced properties that include increased strength, durability, and resistance to wear and corrosion. These exceptional characteristics make it highly suitable for a wide range of mining applications that involve extreme conditions such as heavy loads, abrasive materials, and exposure to water or chemicals. In the mining industry, special steel finds common use in the manufacturing of various equipment and components. Examples include drill bits, cutting tools, crushing and grinding equipment, conveyor belts, and structural components of mining machinery. For instance, drill bits made from special steel alloys exhibit improved hardness and toughness, enabling them to effectively penetrate hard rock formations. Similarly, crushing and grinding equipment that incorporates special steel components can withstand the high stress and impact forces encountered during mineral extraction and processing. Furthermore, special steel alloys offer superior resistance to corrosion and wear, which are prevalent challenges in mining environments. This quality contributes to extending the lifespan of mining equipment, reducing maintenance costs, and enhancing operational efficiency. Additionally, manufacturers have the flexibility to tailor special steel to meet specific requirements, allowing them to optimize the performance of mining equipment for different mining applications and conditions. Overall, the utilization of special steel in mining applications provides numerous advantages in terms of enhanced performance, durability, and cost-effectiveness. Its distinct properties establish it as an indispensable material in mining operations, facilitating the extraction and processing of minerals in a more efficient and sustainable manner.

- Q:How does special steel contribute to the manufacturing of industrial machinery?

- Special steel contributes to the manufacturing of industrial machinery by providing enhanced strength, durability, and resistance to wear and corrosion. It allows for the production of components that can withstand high temperatures, heavy loads, and harsh operating conditions. The unique properties of special steel enable the creation of precision parts, gears, bearings, and tools that are crucial for the efficient and reliable functioning of industrial machinery.

- Q:What are the applications of special steel in the renewable energy sector?

- Special steel plays a crucial role in the renewable energy sector by enabling the development and advancement of various technologies. One of the key applications of special steel in this sector is in the manufacturing of wind turbines. Wind turbine components such as towers, generator frames, rotor hubs, and bearings require high-strength, corrosion-resistant steel to withstand the harsh operating conditions, including strong winds and exposure to moisture. Special steel provides the necessary properties to ensure the longevity and reliability of wind turbines, thus contributing to the growth of wind energy. Moreover, special steel is extensively used in the construction of solar power plants. Solar panel frames, mounting structures, and support systems require steel with excellent structural integrity, durability, and resistance to environmental degradation. Special steel provides these qualities, ensuring the stability and performance of solar installations. In addition, special steel finds applications in the production of components for hydroelectric power plants. The construction of turbines, penstocks, and other hydraulic equipment demands steel with high tensile strength and resistance to corrosion caused by water and sediments. Special steel alloys possess these characteristics, making them ideal for hydroelectric power generation. Furthermore, special steel is utilized in the manufacturing of energy storage systems, such as batteries and fuel cells. These systems often require steel with exceptional conductivity, corrosion resistance, and mechanical strength to ensure efficient and reliable energy storage. Special steel alloys can meet these requirements, making them suitable for use in renewable energy storage technologies. In summary, special steel plays a vital role in the renewable energy sector by offering the necessary properties for the manufacturing of wind turbines, solar power plants, hydroelectric power plants, and energy storage systems. Its high-strength, corrosion-resistant, and durable characteristics enable the development of efficient and reliable renewable energy technologies, contributing to the sustainable energy transition.

- Q:What are the different wear-resistant grades of special steel?

- There are several different wear-resistant grades of special steel available, each with their unique properties and applications. Some of the commonly used grades include: 1. D2 Steel: This grade of steel is known for its high wear resistance and excellent toughness. It is often used in the manufacturing of cutting tools, punches, and dies. 2. M2 Steel: M2 steel is a high-speed steel with exceptional wear resistance and heat resistance. It is commonly used in the production of drill bits, milling cutters, and other tools that require high hardness and wear resistance. 3. A2 Steel: A2 steel is a versatile grade known for its excellent wear resistance and toughness. It is frequently used in the manufacturing of cold work tools, such as blanking dies and gauges. 4. O1 Steel: O1 steel is an oil-hardening tool steel with good wear resistance and dimensional stability. It is commonly used in the production of blades, punches, and other cutting tools. 5. S7 Steel: S7 steel is a shock-resistant grade with high wear resistance. It is often used in the manufacturing of chisels, shear blades, and other tools that require resistance to impact and wear. 6. AR400 Steel: AR400 steel is a specific type of abrasion-resistant steel with a hardness of around 400 Brinell. It is frequently used in heavy-duty applications such as mining equipment, bulldozer blades, and dump truck bodies. These are just a few examples of the different wear-resistant grades of special steel available in the market. The choice of grade depends on the specific requirements of the application, such as the type and intensity of wear, operating conditions, and desired hardness. Consulting with a steel supplier or expert can help in selecting the most suitable grade for a particular application.

- Q:What are the different methods of surface electropolishing for special steel?

- There are several methods of surface electropolishing for special steel, including the use of acid-based or alkaline-based electrolytes, pulse current electropolishing, and reverse current electropolishing. The choice of method depends on factors such as the type of special steel being treated and the desired surface finish.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords