High Quality Sany Spectacle Wear Plate Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

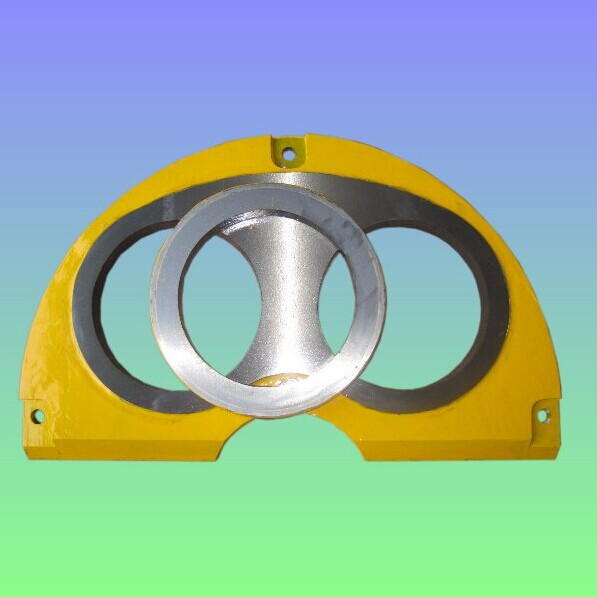

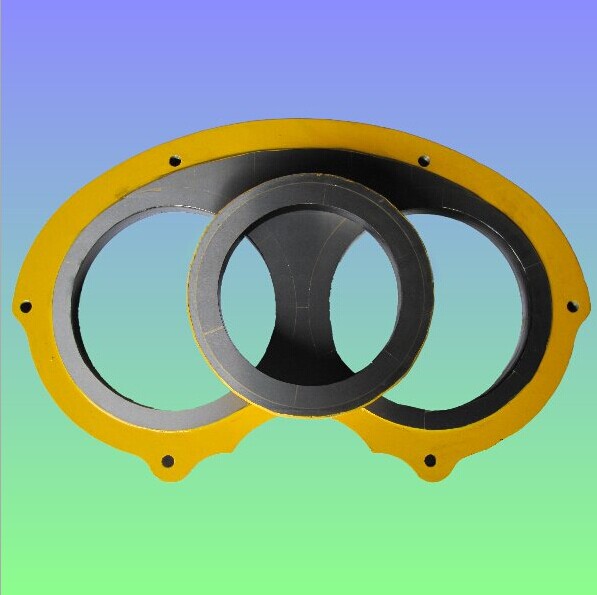

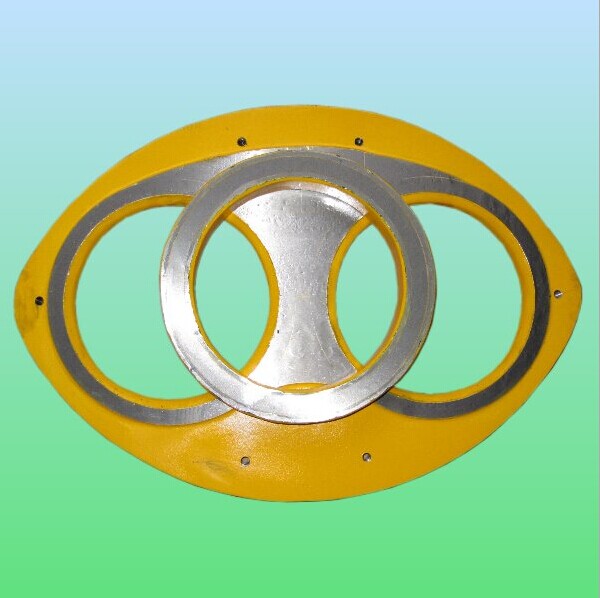

Product Name: High Quality Sany Spectacle Wear Plate Tungsten Carbide

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Sany Pump

Notes: total series of High Quality Sany Spectacle Wear Plate Tungsten Carbide for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our High Quality Sany Spectacle Wear Plate Tungsten Carbide have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs High Quality Sany Spectacle Wear Plate Tungsten Carbide put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some High Quality Sany Spectacle Wear Plate Tungsten Carbide according to customers request?

A4: Yes, we can produce High Quality Sany Spectacle Wear Plate Tungsten Carbide according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q:What are the indications of a worn-out concrete pump clamp?

- There are several indications that a concrete pump clamp may be worn out and in need of replacement. Some common indications include: 1. Leaking: If you notice any leaking around the clamp area while the concrete pump is in operation, it could be a sign of a worn-out clamp. This leaking could be due to a faulty seal or gasket, which may no longer be able to create a tight and secure connection between the pump and the hose. 2. Vibrations and rattling: A worn-out clamp can cause excessive vibrations and rattling during the pumping process. This could be due to the clamp no longer being able to hold the hose firmly in place, leading to movement and instability. 3. Difficulty in tightening: If you find that it is increasingly difficult to tighten the clamp properly, it may indicate that the clamp is worn-out. Over time, the clamp's components can become worn, making it harder to achieve a secure and tight connection. 4. Visual signs of damage: Inspect the clamp for any visual signs of damage, such as cracks, dents, or corrosion. These physical damages can compromise the clamp's ability to function effectively, leading to potential leaks or instability. 5. Excessive wear and tear: If you have been using the same concrete pump clamp for an extended period without replacement, it is advisable to inspect it regularly for signs of excessive wear and tear. This could include worn-out or missing bolts, a deformed clamp body, or any other visible signs of deterioration. It is essential to address any indications of a worn-out concrete pump clamp promptly to ensure the safety and efficiency of the pumping operations. If you observe any of these signs, it is recommended to consult a professional or replace the clamp to avoid potential accidents or disruptions in the concrete pumping process.

- Q:How can a faulty battery affect the operation of the pump?

- A faulty battery can affect the operation of the pump by causing it to lose power or stop working altogether.

- Q:How often should concrete pump pistons be inspected and replaced?

- To ensure optimal performance and prevent malfunctions, it is necessary to regularly inspect and replace concrete pump pistons. The frequency of these inspections and replacements depends on various factors, such as the type and volume of concrete being pumped, as well as the operating conditions of the pump. As a general rule, it is recommended to inspect and replace concrete pump pistons every 500 to 1,000 hours of operation. However, this can vary based on the specific recommendations of the pump manufacturer, the quality of the concrete being pumped, and the maintenance and cleaning practices followed. Regular inspections should be conducted to identify any signs of wear, damage, or deterioration in the pistons. This includes examining the rubber seals, valve plates, and other components that may impact the piston's performance. If any cracks, tears, or excessive wear are detected, immediate replacement is necessary to prevent issues like concrete leakage or pressure loss. In addition to regular inspections, it is essential to follow a preventive maintenance schedule that includes routine cleaning and lubrication of the pistons. This will help extend their lifespan and ensure smooth operation. It is important to note that the recommended intervals for inspection and replacement may vary among different pump manufacturers. Therefore, it is advisable to consult the pump's operation and maintenance manual or seek guidance from the manufacturer or a qualified technician to determine the ideal frequency for inspecting and replacing concrete pump pistons.

- Q:How does a concrete pump agitator motor prevent concrete from settling?

- Constantly agitating the mixture, a concrete pump agitator motor prevents the settling of concrete. Typically equipped with rotating paddles or blades inside the mixing drum, the motor ensures that the concrete remains in a homogeneous state. During transportation, concrete tends to separate as gravity and the natural settling of heavier aggregates take effect. This can lead to a non-uniform consistency, with denser materials sinking and water rising. To counteract this settling process, the agitator motor stirs the concrete continuously. By creating a turbulent flow within the mixing drum, the rotating paddles or blades prevent the heavier aggregates from settling, thus maintaining a consistent mixture. This agitation helps distribute the cement, aggregates, water, and any additional additives evenly throughout the concrete, resulting in a more reliable and uniform end product. By preventing concrete settling, the agitator motor ensures that the mixture remains consistently workable, free from blockages or inconsistencies, and suitable for pumping or pouring. This is particularly crucial in construction projects that require precise and consistent concrete placement. In conclusion, the agitator motor in a concrete pump prevents settling by continuously agitating the mixture, thus maintaining its homogeneity and ensuring a consistent flow during pumping or pouring operations.

- Q:What are the different types of concrete pump hopper screens?

- There is a wide range of hopper screens available for concrete pumps, each designed to meet specific needs and requirements. 1. The wire mesh screen is the most commonly used type. It is made of woven wire mesh and prevents large debris or aggregates from entering the pump system. These screens come in various sizes and can be easily replaced when worn or damaged. 2. Perforated plate screens are made of solid metal plates with small holes or perforations. They are particularly effective in preventing fine particles or sediments from entering the pump system. Perforated plate screens are more durable than wire mesh screens and can withstand heavy-duty applications. 3. Polyurethane screens are made of polyurethane material, which has excellent resistance to abrasion and wear. These screens are commonly used in high-performance concrete pumps that handle abrasive materials. They are highly durable and can be easily cleaned or replaced when necessary. 4. Some concrete pump hoppers are equipped with a vibrating screen, which separates and removes solids or debris from the concrete mixture. The vibrating screen uses vibration to facilitate the separation process, ensuring a cleaner and more consistent concrete flow. 5. Self-cleaning screens are designed with a mechanism that prevents clogging and maintains an uninterrupted concrete flow. These screens, usually made of wire mesh or perforated plate, use mechanical or pneumatic methods to automatically remove debris from the screen surface. When selecting a hopper screen, it is crucial to consider the specific requirements of your concrete pumping operation. Factors such as aggregate size, presence of fine particles, and abrasiveness should be taken into account to ensure optimal performance and longevity.

- Q:What are the causes of pipe blockage in concrete pump?

- Therefore, in the JGJ/T10-95 "concrete pumping construction technical regulations," stipulated that the sand through the 0.315mm sieve shall not be less than 15%.

- Q:What are the different types of concrete pump hoses?

- There are generally two types of concrete pump hoses: steel-reinforced hoses and fabric-reinforced hoses. Steel-reinforced hoses are stronger and more durable, suitable for high-pressure applications and long-distance pumping. Fabric-reinforced hoses are lightweight and flexible, ideal for smaller projects and shorter pumping distances.

- Q:What is the role of a concrete pump hopper grate spring?

- The role of a concrete pump hopper grate spring is to provide tension and support to the hopper grate in a concrete pump. The grate spring is typically made of durable and flexible material, such as steel or rubber, and is designed to keep the hopper grate securely in place while allowing it to move and flex as needed during the concrete pumping process. The hopper grate spring helps to prevent the hopper grate from becoming dislodged or damaged by the force and vibrations generated by the concrete pump. It ensures that the grate remains properly aligned and in position, allowing for the smooth and efficient flow of concrete into the pump. Additionally, the grate spring helps to reduce the impact and stress on the hopper grate, extending its lifespan and reducing the need for frequent repairs or replacements. It acts as a buffer, absorbing and distributing the forces exerted on the grate, which can be significant due to the weight and pressure of the concrete being pumped. Overall, the concrete pump hopper grate spring plays a crucial role in maintaining the integrity and functionality of the hopper grate, ensuring the safe and efficient operation of the concrete pump.

- Q:What are the skills of concrete pump?

- The operator and equipment management personnel should carefully read the instructions, grasp the relevant knowledge of the structural principle, use and maintenance as well as pumping concrete; use and operation of the concrete pump, should be strictly in accordance with the execution of instructions

- Q:What are the layout requirements of concrete pump for building engineering?

- The concrete pump shall be as close as possible to the casting site. In the use of cloth rod work, should make the casting parts as far as possible within the working range of the distribution rod, as little as possible to move the pump, that is able to complete the pouring.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Sany Spectacle Wear Plate Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords