Heat Insulation Aluminum Foil Facing glass wool,aluminum foil insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

It is a kind of elastic glass fiber product made of glass fiber with diameter of only a few microns, and we can also choose moisture-proof facing on-line compound according to customers' requirements. Because of a large number of tiny air interspaces, it has the functions of heat insulation, sound absorption, safe guarding and etc, so it is the best materials of heat insulation and sound absorption in construction.

2.Main features of Glass Wool Blanket:

• Soft and long glass fibers can maximally lessen flying catkins in the construction.

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

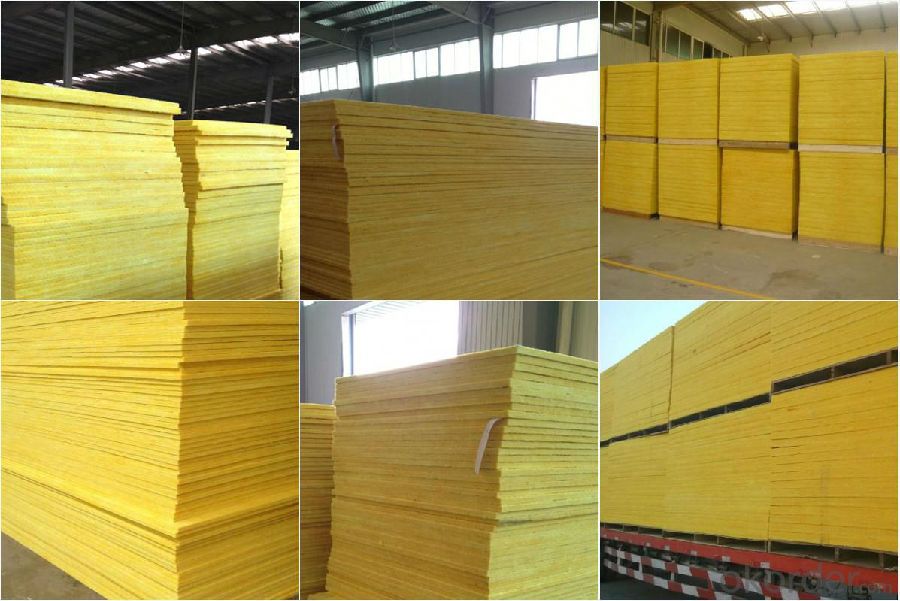

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How does fiberglass mat tissue compare to polyurethane insulation?

- In the construction industry, fiberglass mat tissue and polyurethane insulation are commonly used materials, but they differ in terms of their composition, performance, and applications. Fiberglass mat tissue consists of woven glass fibers and is primarily used to reinforce various materials, including roofing, wall insulation, and fiberglass composites. Its main advantage lies in its high tensile strength, which provides excellent structural support and durability. Additionally, it is resistant to fire and chemicals, making it a suitable option for applications where safety is a concern. In contrast, polyurethane insulation is a foam material known for its exceptional thermal insulation properties. It is frequently utilized in buildings to minimize heat transfer and enhance energy efficiency. With its high R-value, indicating its ability to resist heat flow, it is particularly well-suited for insulation purposes, especially in regions with extreme temperature conditions. Furthermore, polyurethane insulation is lightweight, easy to install, and exhibits good moisture resistance. When comparing fiberglass mat tissue to polyurethane insulation, it is crucial to consider the specific requirements of the project. Fiberglass mat tissue is best suited for applications that necessitate structural reinforcement, such as roofing and composite materials. Its strength and durability make it the preferred choice for such applications. On the other hand, polyurethane insulation excels in terms of thermal insulation. It offers superior heat resistance and possesses a higher R-value compared to fiberglass mat tissue. Therefore, if the primary objective is to enhance energy efficiency and minimize heat transfer, polyurethane insulation would be the superior option. In conclusion, fiberglass mat tissue and polyurethane insulation each have their own advantages and disadvantages. The decision regarding which material to use should be based on the specific needs of the project, whether it be structural support or thermal insulation requirements. Consulting with a professional and taking into account factors such as budget, environmental impact, and local building codes will aid in making an informed decision.

- Q:Can fiberglass mat tissue be used for making lightweight flooring?

- Yes, fiberglass mat tissue can be used for making lightweight flooring. Fiberglass mat tissue is a material that is commonly used in construction and manufacturing industries for its strength, durability, and lightweight properties. It is made by bonding fine fiberglass strands together with a binder, which results in a thin, flexible, and lightweight material. When used in flooring applications, fiberglass mat tissue can provide several advantages. Firstly, its lightweight nature makes it easier to handle and install, reducing the overall weight of the flooring system. This can be particularly beneficial in applications where weight is a concern, such as in aircraft or mobile homes. Additionally, fiberglass mat tissue is known for its excellent strength-to-weight ratio, making it a suitable material for creating lightweight yet strong flooring. It can provide reinforcement and improve the structural integrity of the flooring, making it more resistant to cracking, warping, or other forms of damage. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and fire, making it a suitable choice for areas where these factors are present, such as bathrooms, kitchens, or industrial settings. It also offers good insulation properties, which can help in maintaining a comfortable indoor environment and reducing energy consumption. Overall, fiberglass mat tissue can be an excellent choice for making lightweight flooring due to its strength, durability, moisture resistance, and insulation properties. However, it is important to consider other factors such as the specific requirements of the flooring application, the load-bearing capacity, and the necessary certifications or standards before finalizing the use of fiberglass mat tissue in a flooring project.

- Q:Does fiberglass mat tissue have any fire-resistant properties?

- Yes, fiberglass mat tissue does have fire-resistant properties. Fiberglass is inherently fire-resistant due to its composition. It is made from a combination of glass fibers and a thermosetting resin, which gives it its fire-resistant properties. When exposed to high temperatures or flames, fiberglass mat tissue does not easily ignite or burn. Instead, it resists the spread of flames and can help to contain a fire. This makes fiberglass mat tissue a suitable material for applications where fire protection is required, such as insulation, fire barriers, and fireproof panels. However, it is important to note that while fiberglass is fire-resistant, it is not completely fireproof and can still melt or burn under extreme conditions.

- Q:Can fiberglass mat tissue be used for mold making?

- Typically, fiberglass mat tissue is not employed in the process of mold making. Instead, it serves as a thin and lightweight substance composed of interwoven fiberglass strands. Its primary function lies in fortifying and bolstering composite materials, particularly fiberglass laminates. When it comes to mold making, silicone rubber, urethane rubber, or latex are commonly utilized materials. These possess flexibility and possess the ability to impeccably capture intricate details, making them optimal for generating molds of various objects. Furthermore, they possess excellent release properties, thereby facilitating the effortless removal of the mold from its original counterpart. Conversely, fiberglass mat tissue is rigid and lacks the necessary flexibility required in mold making. Rather, it finds greater suitability in applications necessitating strength and reinforcement, as opposed to the replication of intricate shapes or the creation of molds. Hence, if your aim is to fabricate molds, it is advised to select a material explicitly intended for that purpose, instead of utilizing fiberglass mat tissue.

- Q:Can fiberglass mat tissue be used for reinforcing fiberglass roofs?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass roofs. It is commonly used in the construction industry as a reinforcing material for various applications, including roofs.

- Q:How does the thickness of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is greatly influenced by its thickness. Thicker mat tissues generally offer superior strength and durability compared to thinner ones. When the mat tissue is thicker, there is a higher proportion of resin to glass, resulting in increased stiffness and toughness. This higher resin content improves the overall structural integrity and mechanical properties of the mat tissue, reducing the risk of delamination and enhancing resistance to impact and fatigue. Furthermore, thicker fiberglass mat tissues are more effective in providing thermal and acoustic insulation. The increased thickness allows for a greater concentration of fibers, enhancing the material's ability to trap air and reduce heat transfer or sound transmission. However, it is important to consider the specific application and requirements when determining the appropriate thickness of fiberglass mat tissue. While thicker tissues generally offer better performance, they may also be heavier and more costly. Therefore, it is crucial to strike a balance between the desired performance characteristics and practical considerations such as weight, cost, and ease of installation.

- Q:Is fiberglass mat tissue compatible with vacuum infusion processes?

- Yes, fiberglass mat tissue is compatible with vacuum infusion processes. It is commonly used in vacuum infusion techniques as it allows for the distribution of resin evenly throughout the laminate, resulting in a strong and uniform composite part.

- Q:What are the different reinforcement patterns available for fiberglass mat tissue?

- Some different reinforcement patterns available for fiberglass mat tissue include random pattern, grid pattern, and diamond pattern. Each pattern offers different levels of strength and durability depending on the specific application and requirements.

- Q:Can fiberglass mat tissue be used for making lightweight furniture?

- No, fiberglass mat tissue is not typically used for making lightweight furniture. It is primarily used as a reinforcement material in applications such as insulation, automotive parts, and construction, but not for furniture production.

- Q:Can fiberglass mat tissue be used in automotive manufacturing?

- Indeed, fiberglass mat tissue finds great utility in the realm of automotive manufacturing. Crafted from interwoven glass fibers bonded by a binder, this pliable and lightweight material serves a multitude of purposes within the automotive industry. It excels at reinforcing body panels, constructing structural components, and improving sound and heat insulation. An advantageous attribute of fiberglass mat tissue in the realm of automotive manufacturing lies in its remarkable strength-to-weight ratio. It bestows superb reinforcement capabilities upon the vehicle while adding minimal mass, rendering it an optimal selection for bolstering fuel efficiency and curbing emissions. Furthermore, fiberglass mat tissue boasts exceptional malleability, enabling effortless shaping and molding into intricate geometries requisite for automotive parts. This material readily reinforces regions susceptible to intense stress, including the roof, doors, and undercarriage, thereby augmenting the vehicle's overall robustness and endurance. Moreover, fiberglass mat tissue exhibits outstanding resistance to corrosion, chemicals, and extreme temperatures, engendering its suitability for deployment in diverse automotive environments. It also serves as an effective insulator against sound and heat, effectively abating noise and preserving a comfortable internal temperature. All in all, fiberglass mat tissue has emerged as a cherished resource in automotive manufacturing, owing to its lightweight, sturdy, moldable, and durable properties. The versatility and performance characteristics it embodies render it the preferred choice for numerous automotive manufacturers seeking to heighten the excellence and performance of their vehicles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat Insulation Aluminum Foil Facing glass wool,aluminum foil insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords