HDPE Drainage Geonet used in Construction Earthwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

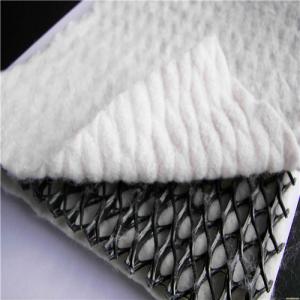

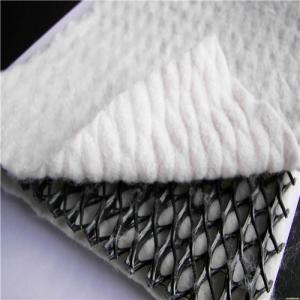

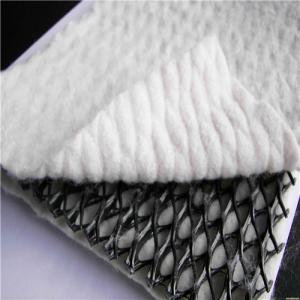

Composite Geonet Description:

Composite geonet is a new type drainage material. It has three layers: three-dimensional geonet and nonwoven geotextile on both sides.

The material of geonet is HDPE, and the material of geotextile can be needle punched PET/PP nonwoven geotextile, and thermalbonded continuous filament nonwoven geotextile.

Composite Geonet Specification:

Thickness of geonet: 5mm to 8mm

Weight of geotextile: 200g/m2, as request

Width: 2m-4m

Length: as request

Composite Geonet Application:

Landfill drainage, roadbed and road drainage, railway drainage, tunnel drainage, underground

structure drainage, the retaining back wall

drainage, gardens and sports grounds drainage.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

4.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

5.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

6.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

7.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q:What are the benefits of using geogrids in slope stabilization?

- Geogrids offer several benefits in slope stabilization, including increased stability, improved load distribution, and enhanced erosion control. They provide reinforcement to the soil, reducing the risk of slope failure and preventing landslides. Geogrids also help distribute the load exerted on the slope, minimizing stress concentration and promoting even weight distribution. Additionally, they enhance erosion control by preventing soil erosion and promoting vegetation growth. Overall, geogrids are an effective and efficient solution for slope stabilization, ensuring long-term stability and safety.

- Q:How do geosynthetic liners prevent seepage in fish ponds?

- Geosynthetic liners prevent seepage in fish ponds by creating a barrier that effectively prevents the leakage of water through the pond's soil. These liners, made from durable materials like high-density polyethylene (HDPE) or ethylene propylene diene monomer (EPDM), are impermeable to water and resist damage from chemicals or UV exposure. By lining the bottom and sides of the pond with geosynthetic liners, they create a watertight seal that ensures minimal seepage, thus maintaining the desired water level for the fish pond.

- Q:What are the advantages of using geosynthetic materials in road pavement rehabilitation?

- There are several advantages of using geosynthetic materials in road pavement rehabilitation. Firstly, geosynthetics can improve the structural integrity of the pavement by providing reinforcement and stabilizing the base layers. This helps in increasing the load-bearing capacity of the road and extending its lifespan. Secondly, geosynthetics can act as a barrier against water infiltration, preventing the weakening of the pavement due to moisture damage. They can also aid in controlling erosion and reducing the risk of potholes and cracks, resulting in a smoother and safer road surface. Additionally, geosynthetic materials are lightweight and easy to handle, making the construction process faster and more cost-effective. They can be easily installed and require minimal maintenance, reducing the need for frequent repairs and saving time and resources. Overall, the use of geosynthetic materials in road pavement rehabilitation offers numerous benefits, including improved structural performance, enhanced durability, increased resistance to moisture damage, and reduced maintenance requirements.

- Q:What is the purpose of using geocells in mining applications?

- The purpose of using geocells in mining applications is to provide a stable and reinforced foundation for mining operations. Geocells are used to reinforce the soil and prevent erosion, thereby improving the overall stability and safety of the mining site. Additionally, geocells can help control surface water runoff and reduce the environmental impact of mining activities.

- Q:Can earthwork products be used in slope stabilization projects?

- Yes, earthwork products can be used in slope stabilization projects. These products, such as geotextiles, geogrids, and geomats, are designed to reinforce and stabilize slopes by improving soil stability, preventing erosion, and enhancing drainage. They are commonly used in various slope stabilization applications, including embankments, retaining walls, and landslide mitigation projects.

- Q:How can geocells be used in grass paving systems?

- Geocells can be used in grass paving systems by providing a stable and reinforced structure for the grass to grow and thrive. The cellular confinement system of geocells helps distribute the load evenly, preventing soil compaction and erosion. This allows for the creation of aesthetically pleasing grassy areas that can withstand vehicular and pedestrian traffic without damaging the underlying soil or compromising the integrity of the grass.

- Q:Why beginners or senior civil engineering and technical personnel are required to continue to learn civil engineering materials

- Civil engineering materials teaching materials mainly introduce the basic composition of civil engineering materials commonly used in civil engineering, material performance, quality requirements, testing methods

- Q:Can earthwork products be used for creating raised planters?

- Yes, earthwork products such as soil, gravel, and rocks can be used for creating raised planters. These materials are commonly used to build the foundation and structure of raised planters, providing a suitable environment for plants to grow.

- Q:How do geogrids aid in reinforcement of bridge abutments in earthwork projects?

- Geogrids aid in the reinforcement of bridge abutments in earthwork projects by providing additional strength and stability to the soil. These grid-like structures are placed within the soil layers to increase their load-bearing capacity and prevent excessive settlement or movement of the abutment. The geogrids distribute the applied loads more evenly, reducing stresses on the abutment and preventing potential failures.

- Q:Can sediment basins be used for large-scale earthwork projects?

- Yes, sediment basins can be used for large-scale earthwork projects. They are commonly employed to control and manage sediment runoff during construction activities, especially in areas with significant soil erosion potential. Sediment basins are designed to collect and retain sediment-laden water, allowing it to settle before being discharged. This helps prevent the deposition of sediment in nearby water bodies, which can have detrimental environmental impacts. The use of sediment basins is an effective erosion and sediment control measure, making them suitable for large-scale earthwork projects where sediment control is necessary.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Drainage Geonet used in Construction Earthwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords