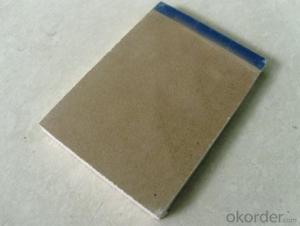

Gypsum Ceiling in Standard Size 595*595*8.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

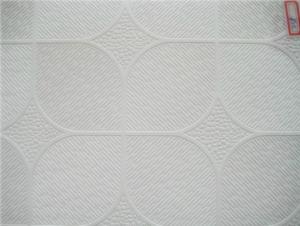

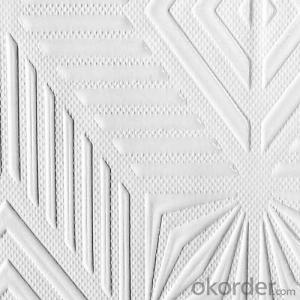

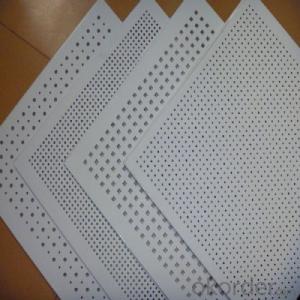

Gypsum Ceiling Tiles

1. Detailed Description:

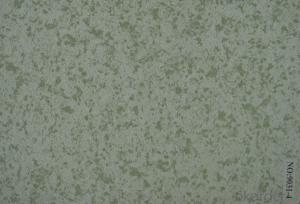

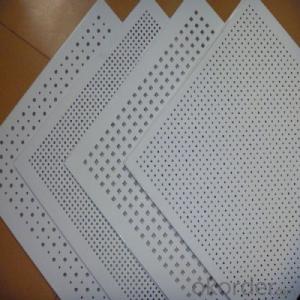

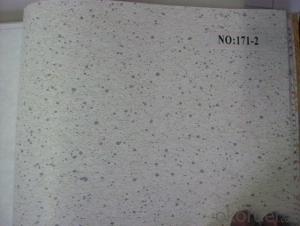

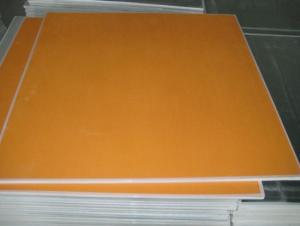

1) Material: Paper-faced gypsum board + PVC facing + Aluminum foil backing

2) Thickness: 7mm, 7.5mm, 8.0mm, 8.5mm, 9mm, 9.5mm, 12mm

3) Sizes: 595*595mm, 595*1195mm; 603*603mm (2’*2’), 603*1210mm (2’*4’)

4) Size tolerance: Length <+/-1.0mm, Width < +/-1.0mm, Thickness <+/-0.5mm

5) Strength: >100N

6) Characters: Non-flammable B1, in accordance with Chinese standard GB8624-1997

7) Installation: Match with ceiling T-bar

8) Packing: Export carton (6pcs, 8pcs or 10 pcs per carton with film)

2. Advantage of the gypsum ceiling tiles:

1) Environment protection product: Adopting natural gypsum material without any harmful material.

2) Non-flammable B1, in accordance with Chinese standard GB8624-1997

3) Heat retaining power

4) Sound insulating: effectively solve sound insulation and fire proof.

5) Not deforming, not cracking: keeping integrity and sound insulation for long under normal changes of.

6) Small expansion: Little coefficient of expansion, deforming under normal temperature.

7) Light weight, convenient to transport.

8) Special breathing performance, comfortable to live in.

9) Sunken proof. Dust proof. Easy clean. Good light reflection. Corrosion proof.

- Q:What is the general use of materials in the ceiling?

- Quality Standard 1, to ensure that the project: light steel keel and cover panel types, specifications and fixed methods must meet the design requirements; light steel keel installation must be correct, connected firmly, no loosening; cover panel should be no delamination, warping, , Missing edges and other defects, the installation must be strong, no loosening. 2, the basic items: light steel skeleton of the boom, large, medium and small keel should be the right position, straight, no bending, no deformation, hanging pieces, connectors should meet the requirements;

- Q:Gypsum board ceiling, need to use long self-tapping nail?

- Monolithic gypsum board (9.5mm or 12mm) with 25mm anti-rust self-tapping screws can be; double gypsum board with 35mm anti-rust self-tapping screws can; other circumstances according to the scene to set.

- Q:Detailed construction technology

- This you have to do more dynamic technology can ah, or certainly not work!

- Q:Home decoration must use gypsum board ceiling? Can you have a ceiling?

- Gypsum board ceiling is mainly used for living room ceiling, it is to gypsum as the main material, adding fiber, adhesive, modifier, by mixing to suppress, dry from. With fire, noise, heat insulation, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction, widely used in ceiling, Wall, plywood, gypsum board is characterized by light, adiabatic, non-combustible, can be sawing nails, sound absorption, humidity, beautiful.

- Q:Ceiling ceiling is gypsum board installed with wood screws will fall?

- Gypsum board although there is a certain strength, but the plasticity is poor, so the screw can only be directly knocked into, can not be screwed into the wood screw, or can not let the gypsum board tightly "hold" the screws. That is, with a straight nail, can only be knocked into the no longer move, a move, gypsum board can no longer "hold" the screws, for the installation of lamps, lamps must be considered after installation, may be affected by the wind, , The impact of screw tightening, coupled with gypsum board because of the installation and materials, etc. reasons, the latter will have a certain deformation, will affect the screw in the gypsum board is loose. Once the screws are loose, the fixture will definitely fall.

- Q:Gypsum board ceiling shot hole how to make up

- Rotten hole processing flat, with two long 45 cm (must be greater than the hole) of the wood keel, the wooden keel even nail in the gypsum board to be used to fill holes.

- Q:Gypsum board ceiling scraping putty treatment and preparation work

- Work: 1, wall treatment of the scraping putty The general wall scraping 2 putty can be, the flatness of the wall requires a lot of local scraping several times, more serious need to find plaster leveling, each putty scraping need to be more than 2 hours. 2, repair the wall to deal with the putty polished After the putty scraping, polished, you can at night, with more than 200 watts of light bulb close to the wall, while grinding side view flatness. Polished easy to produce a lot of dust, need to do a good job wearing masks and so on. 3, the decoration of the wall to deal with the brush primer The dust on the wall putty putty clean, the primer evenly brushing, waiting for the primer dry. 4, repair the wall to deal with the brush finish Under normal circumstances, the topcoat usually need to brush twice, the first pass to wait for its drying only need 2-4 hours. The second time it takes 1-2 days after the job.

- Q:Our living room and restaurant in the middle of a corridor, leading to the various rooms, if the corridor with gypsum board ceiling, living room and restaurant with gypsum line, will be ugly?

- Only the European style, pastoral style, the Mediterranean style and other Western culture as the carrier of the decoration was put gypsum line, or very ugly Oh.

- Q:Decoration with gypsum board ceiling joints need to gap, generally stay much

- Wood keel spacing 1, with the horizontal tube to find the level of the point, with the ink bucket along the horizontal point of playing the horizontal line; 2, light steel keel: wood keel for the edge of the dragon, the lamp slot position with wood keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30 cm is appropriate, hanging spacing 60-80 cm Is appropriate, gypsum board and board between the people to set aside 5-8 mm gap, gypsum board self-tapping screws 1-2 mm and anti-embroidered treatment, to be smooth and solid, shaped to do smooth lines; 3, wood keel: keel at least 3 * 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80 cm is appropriate, hanging bar is strictly prohibited direct use of wooden wedge nails to the top, brush tight fire paint until the wood keel color can not see , The keel on a layer of full-legged rice eucalyptus core 9% board and then on the gypsum board, gypsum board and board between the people to set aside 5-8 mm gap, gypsum board self-tapping screws 1-2 mm and do Anti-embroidered treatment, to be smooth and solid, shaped to do smooth lines; 4, aluminum plate: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board to the pit And the contact with the tile is not tight to use the sealant to play tight; 5, aluminum-plastic plate: wood keel at least 3 * 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80 cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core With a universal adhesive paste aluminum-plastic plate, aluminum-plastic plate and the board between the reserved 3-4 mm gap, has been filled with other colors to play the effect of grid, to be smooth and solid, shaped to do smooth lines , The angle of the fold surface can not be broken.

- Q:Ceiling installation lamp with a minimum of 10 cm, enough

- Ceiling Mount Light with a minimum of 8 cm. General installation requirements 8 to 10 cm can be.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gypsum Ceiling in Standard Size 595*595*8.5mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords