glass fiber continuous filament mat (CFM) for pultrusion profiles

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

- Option:

- 400g/m2

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Introduction

Continuous filament mat is made of continuous fiberglass flament,The filaments are randomly distributed by free fall and then compacted by adhesive bonding. Continuous filament mats suitable for FRP process, for example, pultrusion process, RTM process, flament winding process, molding process and so on.The continuous filament mats are widely used in auto interior, such as sun visor, rear shelf, spare tire cover, fender, refrigerated car box, high voltage resistant insulation for transformers, reinforced profiles, reinforced windows and doors and so on. It also can be used as reinforced materials in GMT, asphalt linoleum, plastic floor geotextile. The reinforced products have high product strength smooth appearance and good moldability.

2.Technical data

| Model No.: | EMS400 | |

| Weight: | 400 grams per sq/m | |

| Width: | 1050-2300mm | |

| Loss on Ignition: | 4-10 | |

| Moistrure: | ≤0.2% | |

3.Advantages

1.The tensile strength and bending strength are better;

2.Cleaning surface;

3.Excellent chemical stability,heating resistance and well insulation;

4.Anti UV, anti aging, to solve the problem of aging products.

5.Not disperse through the resin tank,The best choice for Pultrusion,

4.Application

5.Storage:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C - 35°C, 35% - 65% respectively. Best used within 12 months after production date. Fiberglass products should remain in their original packaging until just prior to use.

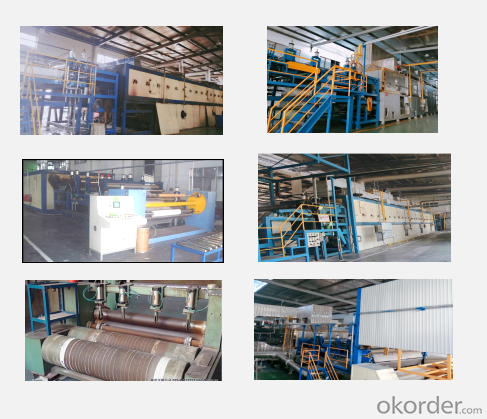

6.Our company:

Our Advantages:

1. Provide the high quality and low price product;

2. 24 hours online reply(English, Spanish and Chinese);

3. The most satisfying service Offered;

4. The safest package and transportation Offered;

5. Good after-sale service offered;

6.Your business relationship with us will be confidential to any third party.

FAQ:

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our top sales for the trade service.

Question 2: Can I try to get a SAMPLE before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: How about the lead time?

Answer: Within15-20 days after getting the prepayment.

Question 4: Where is your factory located? How can I visit there?

Answer: Our factory is located in Nanjing, Jiangsu, China. You can fly to Nanjing airport directly.

Welcome to your visit!

Question 5:Can you customize the product according to our needs?

Answer:Of course,Our company has more than ten years of experienced R & D design team, can customize products according to your needs.

- Q:How does the roll diameter of fiberglass mat tissue affect its handling?

- The roll diameter of fiberglass mat tissue can have a significant impact on its handling. A larger roll diameter generally means a heavier and bulkier roll, making it more challenging to handle and maneuver. This can be particularly important in situations where the fiberglass mat tissue needs to be transported or installed manually. A larger roll diameter may also require more physical effort to lift and move, which can lead to increased strain on the individuals handling it. Moreover, larger roll diameters can also take up more space, making storage and transportation more cumbersome. On the other hand, a smaller roll diameter can make the fiberglass mat tissue easier to handle, as it is lighter and more compact. This can be particularly advantageous in situations where frequent movement and installation are required, such as in construction sites or manufacturing facilities. Additionally, a smaller roll diameter may allow for more efficient storage and transportation, as it takes up less space and can be stacked more easily. This can help optimize logistics and minimize costs associated with storage and transportation. Overall, the roll diameter of fiberglass mat tissue directly affects its handling characteristics, with larger diameters making it more challenging to handle and smaller diameters providing easier handling and improved storage efficiency.

- Q:Can fiberglass mat tissue be used in high-temperature applications?

- No, fiberglass mat tissue is not suitable for high-temperature applications.

- Q:Can fiberglass mat tissue be used in wet environments?

- Yes, fiberglass mat tissue can be used in wet environments. It is resistant to water and can withstand exposure to moisture without losing its structural integrity.

- Q:Can fiberglass mat tissue be used for attic insulation?

- No, fiberglass mat tissue is not typically used for attic insulation. It is more commonly used in the manufacturing of composite materials and as a reinforcement layer in fiberglass products. Attic insulation typically requires materials like fiberglass batts, cellulose, or spray foam insulation, which are designed specifically for thermal insulation purposes.

- Q:How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue, widely utilized in industries such as construction, automotive, and marine, serves as a common type of reinforcement material. When evaluating fiberglass mat tissue in comparison to other reinforcement materials, several factors come into play. First and foremost, fiberglass mat tissue exhibits remarkable strength and durability. With its high tensile strength, it can endure substantial pulling or stretching forces without distorting or breaking. This strength is comparable, if not superior, to reinforcement materials like carbon fiber or aramid fibers. Furthermore, fiberglass mat tissue displays excellent resistance to chemical, moisture, and UV degradation, rendering it suitable for long-term usage in various environments. Another advantage of fiberglass mat tissue lies in its cost-effectiveness. In contrast to other reinforcement materials, fiberglass is relatively affordable, making it a popular choice for manufacturers and builders who require a cost-efficient solution without compromising quality. Its affordability expands its accessibility to a wider array of applications and industries. Moreover, fiberglass mat tissue is renowned for its versatility. It can be molded into different shapes and sizes, allowing for customization and flexibility in design. This adaptability makes fiberglass mat tissue suitable for a broad range of applications, ranging from simple repairs to complex structural reinforcements. However, it is important to note that fiberglass mat tissue may have certain limitations when compared to other reinforcement materials. For instance, it may not possess the same level of stiffness or strength as carbon fiber, which is often preferred in high-performance applications. Additionally, fiberglass mat tissue may exhibit lower resistance to impact or fatigue when compared to materials like aramid fibers. In conclusion, fiberglass mat tissue provides a favorable combination of strength, durability, cost-effectiveness, and versatility, making it a favored choice for numerous applications. While it may have some limitations when compared to other reinforcement materials, its overall performance and affordability render it a widely utilized and dependable option in various industries.

- Q:Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Indeed, insulation in chemical storage tanks can be achieved using fiberglass mat tissue. The exceptional insulation properties of fiberglass render it a fitting substance for tanks that house chemicals. Typically composed of finely interwoven glass fibers, the fiberglass mat tissue constitutes a robust and long-lasting material. Its application to the inner walls of the tank effectively insulates and thwarts heat transfer. Furthermore, fiberglass exhibits corrosion resistance and can endure the detrimental effects of the chemicals commonly stored within these tanks, making it an optimal option for insulation in chemical storage tanks.

- Q:What is the cost of fiberglass mat tissue?

- The cost of fiberglass mat tissue can vary depending on factors such as the thickness, size, and brand. It is best to check with suppliers or retailers for specific pricing information.

- Q:Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. Fiberglass mat tissue is a lightweight material made from randomly oriented fiberglass strands. It is commonly used in composite manufacturing to provide additional strength and reinforcement to fiberglass laminates. When making fiberglass molds, the mat tissue can be used as a surface layer to create a smooth and durable finish. It helps to prevent air bubbles, improve the overall strength of the mold, and provide a good surface for the application of release agents or gel coats. However, it is important to note that fiberglass mat tissue alone may not be sufficient to create a rigid and durable mold. It is often used in combination with other fiberglass materials, such as chopped strand mat or woven roving, to provide additional strength and thickness to the mold. Overall, fiberglass mat tissue can be a useful component in making fiberglass molds, but it is typically used in conjunction with other materials to achieve the desired properties.

- Q:How does fiberglass mat tissue compare to cellulose insulation?

- Fiberglass mat tissue and cellulose insulation differ in terms of material composition and insulation properties. Fiberglass mat tissue is made from fine glass fibers, while cellulose insulation is composed of recycled paper fibers treated with fire-retardant chemicals. Fiberglass mat tissue offers higher R-value, meaning it provides better thermal insulation and energy efficiency. Additionally, it is resistant to moisture and does not promote mold growth. On the other hand, cellulose insulation is more affordable, environmentally friendly, and provides better sound insulation. Ultimately, the choice between the two depends on specific insulation needs, budget, and environmental considerations.

- Q:Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- Yes, fiberglass mat tissue is suitable for insulation in high-rise buildings. Fiberglass mat tissue is a widely used insulation material that offers excellent thermal and acoustic properties. It is lightweight, flexible, and easy to install, making it ideal for use in high-rise buildings where efficiency and effectiveness are crucial. Fiberglass mat tissue also has excellent fire-resistant properties, which is an essential requirement for buildings with multiple floors. Additionally, it is resistant to moisture, mold, and pests, ensuring long-term durability and performance. The material can be easily customized to fit various areas of the building, including walls, floors, and ceilings, providing consistent insulation throughout the structure. Overall, fiberglass mat tissue is a reliable and cost-effective insulation option for high-rise buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

glass fiber continuous filament mat (CFM) for pultrusion profiles

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

- Option:

- 400g/m2

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords