Glass Blanket Glass Wool Glass Wool Building Materials With CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

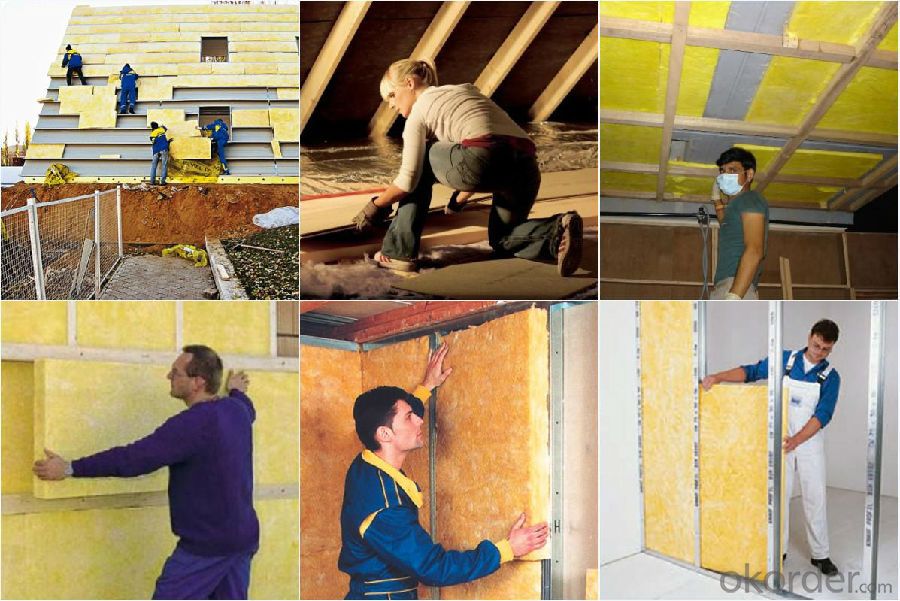

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the different reinforcement orientations available for fiberglass mat tissue?

- Fiberglass mat tissue offers several reinforcement orientations, each intended for specific purposes in different applications. One common orientation is unidirectional reinforcement, where fibers align in one direction. This orientation provides great strength and stiffness in that alignment, making it suitable for applications requiring resistance to tension or bending forces in a single direction. Another orientation is bidirectional reinforcement, where fibers align in two perpendicular directions. This orientation provides equal strength and stiffness in both directions, making it ideal for applications needing resistance to tension and compression forces. Structural components like panels, pipes, and tanks commonly employ bidirectional reinforcement. A third orientation is randomly oriented reinforcement, where fibers distribute randomly. This orientation offers isotropic properties, meaning it provides similar strength and stiffness in all directions. Random reinforcement is often used in applications requiring uniform strength and flexibility, like automotive parts, boat hulls, and sporting goods. Furthermore, hybrid reinforcement orientations are available, combining different fibers or orientations to meet specific performance requirements. These hybrids offer a combination of strength, stiffness, flexibility, and other desired properties, making them suitable for a wide range of applications. Overall, the choice of reinforcement orientation for fiberglass mat tissue depends on the application's specific requirements, including desired mechanical properties, forces to be resisted, and other performance considerations.

- Q:Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q:How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation are two different types of insulation with their own unique characteristics and benefits. Fiberglass mat tissue is a lightweight and flexible material made from spun glass fibers that are arranged into a mat. It is commonly used in the construction industry for thermal and acoustic insulation purposes. Fiberglass mat tissue is relatively easy to install and provides good thermal resistance, helping to regulate temperature and reduce energy loss. However, it may not be as effective in sealing air leaks or filling gaps compared to spray foam insulation. On the other hand, spray foam insulation is a liquid mixture that expands into a foam after being sprayed. It fills gaps and crevices, creating an airtight seal that helps to prevent air leakage and reduce energy consumption. Spray foam insulation can also provide a higher R-value (a measure of thermal resistance) compared to fiberglass mat tissue, making it more efficient in terms of insulation performance. However, the installation process for spray foam insulation can be more complex and may require professional assistance. In summary, fiberglass mat tissue is a cost-effective and easy-to-install insulation option that offers good thermal resistance but may be less effective in sealing air leaks. Spray foam insulation, on the other hand, provides superior insulation performance and air sealing capabilities, but may require professional installation and can be more expensive. Ultimately, the choice between the two will depend on factors such as budget, specific insulation needs, and the desired level of air sealing.

- Q:Can fiberglass mat tissue be used for repairing fiberglass bathtubs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass bathtubs. It is commonly used as a reinforcement material in fiberglass repairs, providing added strength and durability to the repaired area. The tissue can be easily applied and works well for repairing cracks, chips, or other damage on fiberglass bathtubs.

- Q:Can fiberglass mat tissue be used for insulating windows?

- Certainly! Insulating windows is possible with the utilization of fiberglass mat tissue. This lightweight and adaptable material is frequently employed for insulation objectives. With its commendable thermal resistance, it effectively diminishes the escape or entry of heat through windows. By simply affixing a layer of fiberglass mat tissue onto the window surface, it greatly enhances the window's insulation capabilities, thereby reducing drafts and heat transfer. Moreover, this multifunctional fiberglass mat tissue also effectively minimizes noise transmission, rendering it a versatile choice for both thermal and acoustic insulation purposes.

- Q:What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The lifespan of fiberglass mat tissue in cryogenic applications may vary, depending on factors like material quality, specific cryogenic environment, and maintenance and handling practices. Fiberglass mat tissue is renowned for its exceptional insulation properties and ability to withstand extreme temperatures. It is commonly utilized in cryogenic applications to offer thermal insulation and structural support. Under well-maintained and controlled cryogenic conditions, fiberglass mat tissue can endure for several decades. However, it should be noted that exposure to intense thermal cycling, mechanical stress, and chemicals can impact its performance and lifespan. To ensure the longevity of fiberglass mat tissue in cryogenic applications, it is crucial to conduct regular inspections, maintenance, and adhere to the manufacturer's guidelines. Promptly addressing any signs of degradation or damage is also recommended to prevent potential issues or failures.

- Q:Does fiberglass mat tissue provide any sound insulation?

- Yes, fiberglass mat tissue does provide sound insulation. Its dense and fibrous structure helps absorb and dampen sound waves, reducing noise transmission.

- Q:What are the different methods of bonding fiberglass mat tissue to other materials?

- There are several methods of bonding fiberglass mat tissue to other materials, each with its own advantages and considerations. Some of the common methods include: 1. Mechanical Bonding: This method involves physically interlocking the fiberglass mat tissue with the other material. It can be achieved through techniques such as stitching, stapling, or using mechanical fasteners like screws or nails. Mechanical bonding provides a strong and durable connection, but it may require additional hardware and can be time-consuming. 2. Adhesive Bonding: Adhesive bonding is a popular method that uses adhesives or glue to join the fiberglass mat tissue with the other material. This method offers flexibility, as there are various types of adhesives available for different applications. It is important to choose an adhesive that is compatible with both the fiberglass mat tissue and the other material. Proper surface preparation and application techniques are crucial for achieving a strong bond. 3. Resin Infusion: Resin infusion is a process where a liquid resin is infused into the fiberglass mat tissue and other materials, creating a strong bond when cured. This method is commonly used in manufacturing composite products, as it allows for a seamless and uniform bond. Vacuum bagging or resin infusion techniques are typically employed to ensure proper resin distribution and consolidation. 4. Thermal Bonding: Thermal bonding involves the use of heat to bond the fiberglass mat tissue to another material. This method is particularly suitable for thermoplastic materials, as they can be softened and fused together with heat. Techniques such as heat welding or ultrasonic welding are commonly used for thermal bonding. It is important to ensure that the heat does not damage or degrade the fiberglass mat tissue during the bonding process. 5. Fusion Bonding: Fusion bonding is a method where the fiberglass mat tissue and the other material are heated to a molten state and then brought into contact to form a bond. This technique is commonly used in the manufacturing of thermosetting plastics or joining thermoplastic materials. Fusion bonding can provide a strong and seamless bond, but it requires careful control of temperature and pressure to ensure proper bonding without causing damage. In summary, the different methods of bonding fiberglass mat tissue to other materials include mechanical bonding, adhesive bonding, resin infusion, thermal bonding, and fusion bonding. The choice of bonding method depends on factors such as the materials being bonded, the desired strength and durability, and the specific application requirements.

- Q:What is the expected lifespan of fiberglass mat tissue in power generation applications?

- The lifespan of fiberglass mat tissue in power generation applications can vary depending on a range of factors, including the specific application, environmental conditions, and maintenance practices. However, fiberglass mat tissue is renowned for its durability and longevity, making it a popular choice in power generation. Typically, fiberglass mat tissue can endure for approximately 20 to 30 years in power generation applications. This longevity is attributed to its exceptional resistance to corrosion, heat, and chemicals, which are commonly encountered in power generation facilities. Additionally, fiberglass mat tissue can withstand high mechanical stress and maintain its structural integrity over extended periods. Nevertheless, it is important to acknowledge that the lifespan of fiberglass mat tissue can be influenced by factors such as exposure to extreme temperatures, humidity, and chemicals, as well as the frequency and quality of maintenance and inspections. Ensuring regular inspections and proper maintenance is crucial for significantly extending the lifespan of fiberglass mat tissue in power generation applications. To determine the specific expected lifespan of fiberglass mat tissue for a particular power generation application and operating conditions, it is advisable to consult with manufacturers and industry experts.

- Q:What is the delamination strength of fiberglass mat tissue?

- The delamination strength of fiberglass mat tissue refers to its ability to resist separation or peeling of layers within the material. It is a measure of the adhesive strength between the fibers and the binder in the mat. The specific delamination strength of fiberglass mat tissue can vary depending on factors such as the manufacturing process, binder type, and overall composition of the material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Blanket Glass Wool Glass Wool Building Materials With CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords