Germany Standard GASS Aluminum Shoring System ledger frames located at any position along the leg

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000 m²/month

- Option:

- size

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

Benefits of the ledge frame:

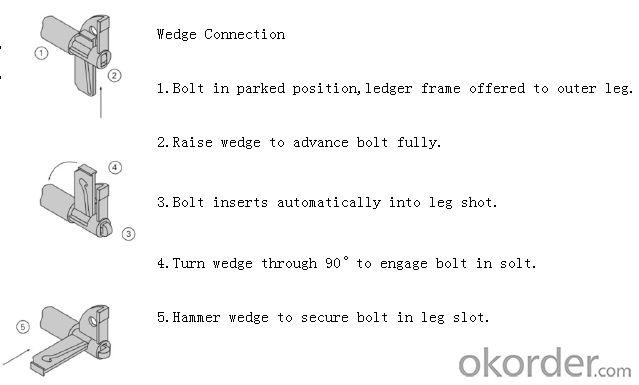

※ Only four wedge connections per frame result in fast installation

※ Clearly visible wedge results in easy identification

that ledger frame is safety and correctly installed.

※ Ledger frame can be removed from an erected structure

to enable personnel and material access.

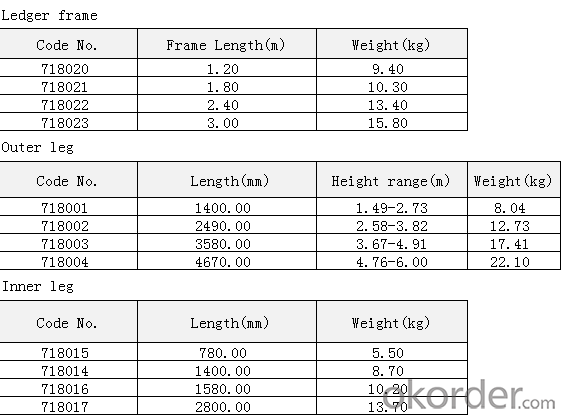

※ Ledger frames in four sizes offer the user versatility

with a minimum number of componens.

※ When utilising access platforms,top rung of ledger frame provides a secure handrail.

Benefits of the outer leg:

※ Eight slot profile allows versatility for attachment of ledge frames in multiple directions.

※ No loose parts.

※ Interlocking head plate eliminates eccentricity.

※ Raised "lip"on head ensures that bolted fixings,leg to leg and leg to beam are easily located and secured eliminating eccentricity.

※ Sprung latch design enables inner leg to be secured safely every time.

※ Eight point profile provides high rigidity to inner leg.

Benefits of the inner leg:

※ Provides up to 1314mm extension with the standard length inner leg (1680mm)2200mm extension with the special length inner leg.

※ Interlocking base plate eliminates eccentricity.

※ Dry-coated thread requires no additional lubricant.

※ Cast collar for optimum strength.

※ Removable grub screw to prevent over extension and to allow for collar replacement.

- Q:Mechanical bearings, all types? Roughly

- The separable bearing is composed of a raceway and a needle roller and cage assembly that can be arbitrarily assembled with a punched thin raceway (W) or a machined thick raceway (WS). A non separable bearing is an integral bearing consisting of a precision machined raceway and a needle and cage assembly. This type of bearing can bear one-way axial load. With small space, it is beneficial to the compact design of machinery. Most of them only use needle roller and cage assembly, and the installation surface of shaft and shell is used as raceway surface.

- Q:Construction Engineering, moving equipment and stationary equipment, respectively

- 2. Static equipment: reaction equipment (code R). Such as reactor, reaction kettle, decomposition pot, polymerizer, autoclave, converter, digester, steam ball, sulfonation pot, gas producer and so on. Heat exchange equipment (code H). Such as tubular waste heat boiler, heat exchanger, evaporator, condenser, cooler, heater, sterilization pot, water jacket, etc. for dyeing dryer, steamer, cooker, gas preheating. Separation equipment (code S)

- Q:Where are the hanging baskets for the building?

- It is strictly prohibited to use hanging baskets as vertical transport facilities for personnel and materials; no staff member is allowed to climb from a basket to a B basket

- Q:What is a door rack for a construction site? How high is it generally?

- This depends on the erection of the height of the general 3 steps and within 5-6 yuan a meter, assuming the erection of 4.5 meters high, 22.5-27 yuan a square. This is calculated in accordance with single-layer, the higher the more expensive, 9 meters in 65 yuan or so square. In accordance with the establishment of meters, in accordance with the erection of the volume of the calculation.

- Q:Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product qualification certificate means the qualified certificate, qualified label or qualified seal issued by the manufacturer to indicate the quality of the products manufactured by the factory and qualified on the package of the product or product. This is the producer's guarantee of the quality of its products, and also the obligation of a product to be stipulated by the law.

- Q:Where does Heilongjiang do the most construction machinery?

- It is mainly used for national defense construction project, the construction of transportation, energy industry construction and production, mining and other industrial raw materials, construction and production, forestry and water conservancy construction, industrial and civil construction, city construction and environmental protection.

- Q:What is the use of spare parts prices in Chinese market by foreign companies?

- You might be gathering information for him. You have no data for one person, if there are several people? They can analyze a lot of things through big data. You can't find out, you're OK. Once you find out, your whole life is over.

- Q:What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ eliminate dangerous source: eliminate the risk source of the system can fundamentally prevent accidents. But an important point of system safety is that it is impossible to completely eliminate all sources of danger and that people can only selectively eliminate several specific sources of danger. Generally speaking, when the risk of a dangerous source is higher, we should first consider whether we can take measures to eliminate it. A dangerous source can be completely eliminated by selecting the proper production process, technology, equipment, reasonable design, structural form or suitable raw material. For example: instead of the power system with pneumatic or hydraulic system, to prevent the occurrence of electrical accidents; instead of compressed air system for hydraulic system, to avoid the pressure vessel, pipeline rupture caused by shock wave; with incombustible materials instead of combustible materials, to prevent the occurrence of fire. It should be noted that sometimes measures are taken to eliminate certain sources of danger, but new sources of danger may be brought about. For example, an electric pneumatic system instead of a power system can prevent electrical accidents, but a physical explosion accident may occur in the compressed air system.

- Q:Construction machinery production need to deal with what documents?

- The person in charge of the enterprise, the person in charge of the project, full-time safety management personnel in "safety assessment qualified" column content according to the "three persons" Safety Assessment Certificate (fill in the contents of enterprise work safety management staff should meet the enterprise production safety management, the safety management department staff with the qualification to the total contract for not less than 5, not less than 3 professional contracting labor subcontracting, not less than 1; the construction site should be equipped with full-time safety management personnel according to the project size can be determined, according to the construction area of less than 10 thousand M2 project has at least a part-time staff of more than 10 thousand M2; project 1 - 2 full-time staff; more than 50 thousand M2 large sites, according to different professional safety management group);

- Q:What functions should be achieved in mechanical structure design?

- The function of the mechanical structure is mainly realized by the geometry of the machine parts and the relative position between the parts. The geometry of a part is made up of its surface, and a part usually has a number of surfaces, some of which are in direct contact with the surface of other parts, and this part of the surface is referred to as the functional surface. The connecting part between the functional surfaces is called the join surface

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Germany Standard GASS Aluminum Shoring System ledger frames located at any position along the leg

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 8000 m²/month

- Option:

- size

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords