Germany standard D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

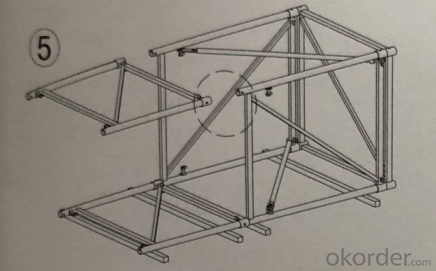

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

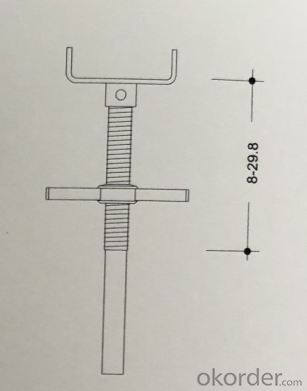

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

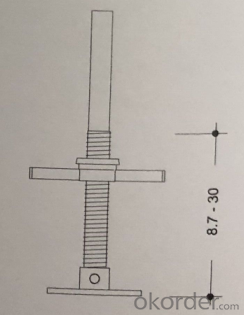

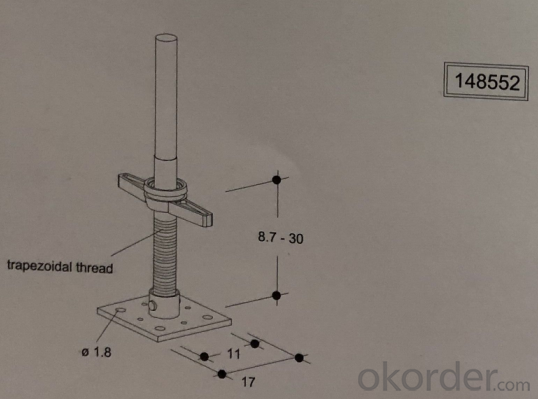

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

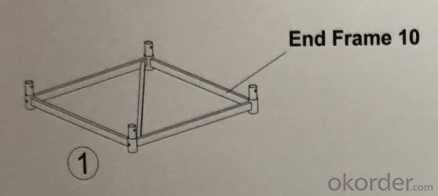

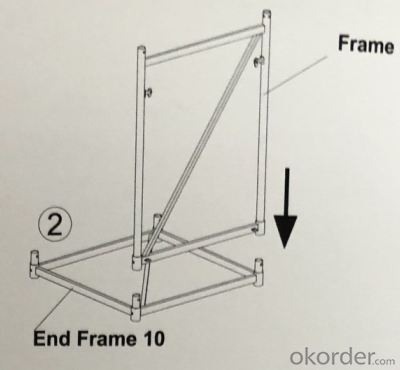

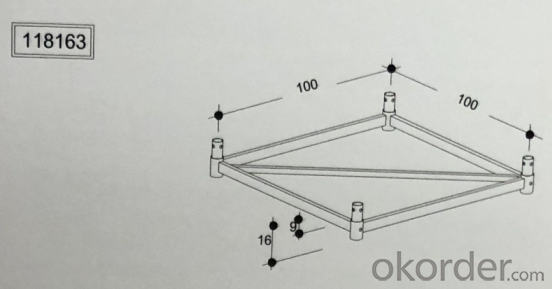

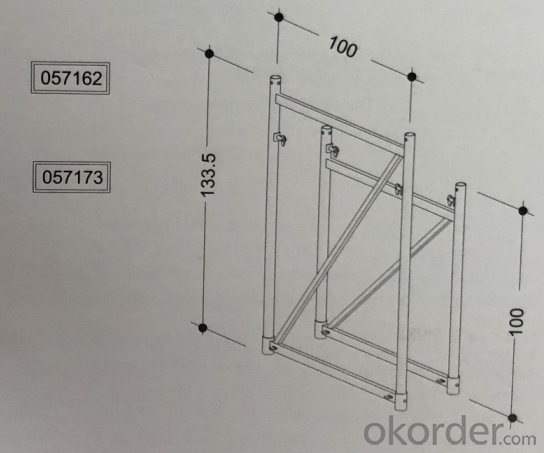

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

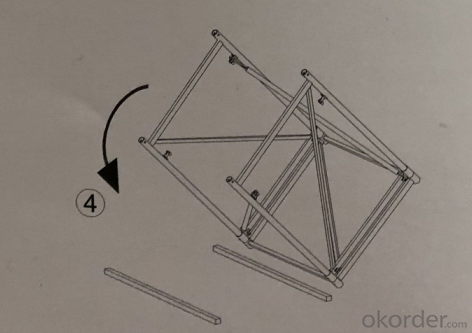

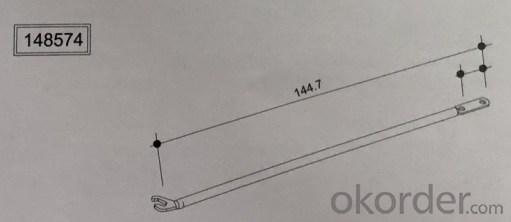

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q:Are steel props suitable for use in underground utility tunnel construction?

- Yes, steel props are suitable for use in underground utility tunnel construction. Steel props provide strong structural support and can withstand the weight and pressure of the surrounding soil or rock. They are durable, versatile, and easily adjustable, making them ideal for supporting the tunnel walls and roof during construction. Additionally, steel props can be used to maintain the stability of the tunnel throughout its lifespan, ensuring the safety and longevity of the underground utility infrastructure.

- Q:Can steel props be used for temporary support during demolition work?

- Yes, steel props can be used for temporary support during demolition work. Steel props are commonly used in construction and demolition projects to provide temporary support to structures or walls that are being removed. They are adjustable in height and can be easily installed and removed. Steel props are strong and sturdy, capable of withstanding the weight and pressure exerted during demolition work. They provide stability and prevent any potential collapse or damage to surrounding structures. Therefore, they are a reliable choice for temporary support during demolition work.

- Q:How do you prevent steel props from sliding on icy surfaces?

- In order to prevent steel props from sliding on icy surfaces, there are several actions that can be taken: 1. Incorporate anti-slip mats or grips: Position rubber or anti-slip mats beneath the steel props to establish traction and prevent sliding. These mats are specifically designed to grasp onto the icy surface, generating friction and ensuring stability. 2. Fasten props with straps or clamps: Utilize straps or clamps to secure the steel props to nearby structures, such as walls or poles. This will assist in stabilizing the props and preventing sliding on the icy surface. 3. Increase weight or ballast: Enhancing the weight on the steel props can enhance stability and decrease the likelihood of sliding. Additional weights can be attached to the props, or sandbags can be used as ballast to anchor them down. 4. Establish a stable base: Remove any snow or ice from the ground where the steel props will be placed. Level the surface and ensure it is free from any debris that could affect stability. If feasible, create a solid foundation for the props by using plywood or other flat materials. 5. Implement ice melt or traction aids: Apply ice melt or other traction aids to the surface surrounding and underneath the steel props. These substances can assist in melting the ice and improving grip, thereby reducing the risk of sliding. 6. Monitor and maintain: Regularly inspect the props and the surrounding area for any indications of movement or instability. If necessary, readjust the props, add more traction aids, or reinforce the stability measures to maintain a secure setup. Ensuring safety and taking necessary precautions when working with steel props on icy surfaces is of utmost importance. By implementing these preventive measures, you can minimize the risk of sliding and ensure a stable and secure setup.

- Q:Are steel props suitable for supporting walls during demolition?

- Yes, steel props are suitable for supporting walls during demolition. Steel props are strong and durable, making them effective in providing the necessary structural support to prevent collapses during the demolition process. They can be easily adjusted and installed, allowing for flexibility in supporting walls of different sizes and weights.

- Q:Can steel props be used in mining tunnel construction?

- Steel props are indeed capable of being utilized in the construction of mining tunnels. In construction, steel props are frequently employed to temporarily bolster structures while they are being built or maintained. During mining tunnel construction, steel props can play a vital role in upholding the tunnel's roof and walls, thus guaranteeing stability and averting collapses or cave-ins. Their height can generally be adjusted, enabling them to be tailored to the tunnel's specific demands. Furthermore, steel props are renowned for their robustness and immense load-bearing capacity, rendering them well-suited for the demanding conditions that are frequently encountered in mining operations.

- Q:What are the potential risks and hazards associated with steel props?

- Steel props, also referred to as adjustable steel props or acrow props, find frequent use in construction and temporary support systems. While they offer several advantages, their use comes with potential risks and hazards. 1. Structural Failure: One of the most significant hazards involves the possibility of structural failure. Steel props can collapse or buckle if subjected to excessive loads or if installed incorrectly. Such incidents can result in severe injuries or even fatalities for workers and bystanders. 2. Overloading: Another risk arises from overloading the props beyond their weight-bearing capacity. Should the load exceed the props' specifications, they may deform or fail, leading to accidents or damage to nearby structures. 3. Improper Placement: Inadequate placement of steel props can pose hazards. If not correctly and securely positioned, they may slip or fall, thereby causing instability in the supported structure and potential risks for workers. 4. Insufficient Bracing: Insufficient bracing can also give rise to risks. Steel props require proper bracing to ensure lateral stability and prevent buckling or collapse. Failure to provide adequate bracing may result in accidents or damage to the supported structure. 5. Inadequate Maintenance: Failure to conduct regular inspections and maintenance can lead to risks. Over time, steel props may develop rust, corrosion, or other structural weaknesses that compromise their integrity. Neglecting to promptly identify and address these issues can increase the likelihood of accidents. 6. Poor Training and Supervision: Insufficient training and supervision of workers using steel props can contribute to hazards. Without adequate knowledge of usage guidelines, workers may fail to assess loads properly, install the props correctly, or ensure appropriate bracing, thereby increasing the risks associated with their use. 7. Falling Objects: When steel props support scaffolding or other temporary structures, falling objects become a hazard. Insecurely fastened or stored materials or tools may fall from the elevated platform, potentially causing injuries to workers or bystanders. To mitigate these risks and hazards, it is crucial to comply with safety regulations and standards, provide comprehensive training to workers, regularly inspect and maintain steel props, and ensure proper installation and bracing. Additionally, employing suitable personal protective equipment and implementing safety measures like barricades or warning signs can help minimize the potential dangers associated with steel props.

- Q:What are the safety precautions to consider when working with steel props?

- When working with steel props, several safety precautions should be considered. Firstly, it is crucial to ensure that the props are inspected and properly maintained before use to identify any damage or defects. Additionally, workers should be trained on how to correctly assemble and dismantle the props to avoid accidents. It is important to follow the manufacturer's guidelines and recommendations for proper usage and weight limits. Adequate personal protective equipment, such as gloves and safety boots, should be worn to protect against potential injuries. Finally, a clear and designated work area should be established to prevent tripping hazards and ensure the safe movement of personnel and equipment around the props.

- Q:Can steel props be used in the construction of tunnels or underground passages?

- Tunnels or underground passages can indeed utilize steel props. These props, frequently employed in construction projects like tunnels and underground passages, serve as both temporary and permanent support systems. Their purpose is to ensure stability, strength, and load-bearing capacity, thus guaranteeing the structure's safety during construction and in the long run. Given their adjustability, steel props are easily installed and removed, making them suitable for a variety of underground construction applications. Furthermore, steel, being both durable and robust, can withstand the challenging conditions often encountered in tunneling projects, such as high pressure, ground movements, and vibrations. In summary, steel props are a dependable and widely used solution for supporting tunnels and underground passages during construction.

- Q:Can steel props be used for supporting temporary event structures?

- Yes, steel props can be used for supporting temporary event structures. Steel props are strong and durable, making them suitable for providing stability and support to temporary structures such as stages, tents, or exhibition booths. They can withstand heavy loads and are adjustable in height, allowing for flexibility in setup and ensuring the structural integrity of the temporary event structures.

- Q:How do steel props compare to telescopic props?

- Construction projects commonly use steel props and telescopic props to support vertical loads, but they have distinct differences. Adjustable steel props, also called acrow props or adjustable steel props, are usually made of steel tubes and have a screw thread mechanism for height adjustment. Their strength and durability make them ideal for supporting heavy loads. They are commonly used for shoring, formwork, and supporting beams and columns during construction. They can be easily adjusted to the desired height and come in various sizes to accommodate different load requirements. On the other hand, telescopic props, also known as aluminum props, are made of lightweight aluminum tubes. They have a telescopic mechanism that allows for quick and easy height adjustment. Telescopic props are known for their portability and ease of handling. They are commonly used in lightweight construction projects, like residential buildings, where smaller loads need support. When comparing steel props to telescopic props, several factors should be considered: 1. Load capacity: Steel props are generally stronger and have a higher load capacity than telescopic props. They are designed to handle heavier loads and are more suitable for supporting large structures or heavy equipment. 2. Durability: Steel props are known for their robust construction and longevity, making them suitable for long-term use. Telescopic props, while still durable, may not withstand heavy loads or rough handling as well as steel props. 3. Adjustability: Both types of props offer adjustability, but the mechanisms differ. Steel props use a screw thread mechanism for precise height adjustment and secure locking. Telescopic props, on the other hand, have a telescopic mechanism that allows for quick and easy height adjustments, but they may not provide the same level of precision as steel props. 4. Portability: Telescopic props are lighter and more portable than steel props due to their aluminum construction. This makes them easier to transport and handle on construction sites, especially in projects that require frequent adjustments. In conclusion, steel props are generally preferred for heavy-duty applications and projects that require higher load capacities, durability, and precise adjustments. Telescopic props, on the other hand, are more suitable for lightweight construction projects that require portability and quick height adjustments. The choice between these two types of props ultimately depends on the specific requirements of the construction project at hand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Germany standard D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords