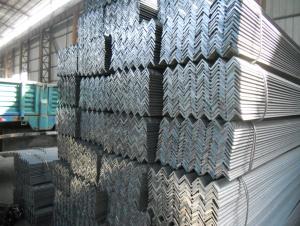

GB Standard Steel Angle Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request.

2. Length: 6m, 9m, 12m.

3. Sizes:

| Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

| 75*75*6 | 6.905 | 80*80*6 | 7.376 |

| 75*75*7 | 7.976 | 80*80*7 | 8.525 |

| 75*75*8 | 9.03 | 80*80*8 | 9.658 |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C.

Material details:

Alloy No | Grade | Element (%) | | ||||

C | Mn | S | P | Si | | ||

| | |||||||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | | ||||

Thickness (mm) | | ||||||

≤16 | >16--40 | >40--60 | >60--100 | | |||

≥ | | ||||||

|

|

|

|

|

| | |

Q235 | B | 235 | 225 | 215 | 205 | | |

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | | |||

Thickness (mm) | | ||||||

| ≤16 | >16--40 | >40--60 | >60--100 | | ||

≥ | | ||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q:Can steel angles be used for fencing and gates?

- Absolutely, fencing and gates can indeed utilize steel angles. Steel angles have gained significant popularity in the realm of fencing and gate installations owing to their exceptional strength, durability, and versatility. These angles offer structural reinforcement and can be effortlessly welded or bolted together, resulting in robust and impregnable fencing or gate frameworks. Moreover, steel angles possess remarkable resistance against weathering and corrosion, rendering them ideal for outdoor applications. Furthermore, they can be tailored to various lengths, heights, and designs, thereby allowing for boundless possibilities in creating diverse fence and gate styles. In conclusion, steel angles serve as a dependable and efficient material for all fencing and gate ventures.

- Q:Can steel angles be used in architectural sculptures and installations?

- Yes, steel angles can be used in architectural sculptures and installations. Steel angles are versatile and commonly used in construction due to their strength and durability. They can be easily welded, bolted, or attached using other methods, making them ideal for creating intricate and complex structures. Steel angles can be shaped and formed into various angles and curves, allowing for creative and unique designs in architectural sculptures and installations. Additionally, steel angles can be finished with different coatings or paints to enhance their aesthetic appeal and protect them from corrosion, making them a suitable choice for both indoor and outdoor installations. Overall, steel angles offer the necessary strength, flexibility, and aesthetic possibilities required for architectural sculptures and installations.

- Q:How do you calculate the buckling strength of a steel angle?

- To calculate the buckling strength of a steel angle, several factors need to be considered. The buckling strength refers to the ability of the angle to resist buckling or collapse under applied loads. Firstly, the geometry of the steel angle must be determined. This includes the dimensions of the angle, such as the length of the legs and the thickness of the steel. Additionally, the cross-sectional properties, such as the moment of inertia and the section modulus, need to be calculated. Next, the effective length of the angle needs to be determined. The effective length is a measure of how restrained the angle is against buckling. It depends on factors such as the boundary conditions and the connection details. The effective length can be different for different modes of buckling, such as flexural or torsional buckling. Once the effective length is determined, the critical buckling load can be calculated using an appropriate buckling equation. There are several buckling equations available, depending on the boundary conditions and the mode of buckling. For example, the Euler buckling equation can be used for long, slender angles subjected to axial compression. Other equations, such as the Johnson buckling equation, may be used for more complex loading scenarios. The critical buckling load can then be converted to an allowable stress using a suitable safety factor. The safety factor accounts for uncertainties in the calculation and ensures that the angle can safely carry the applied load without buckling. The safety factor is typically specified by design codes or industry standards. In summary, calculating the buckling strength of a steel angle involves determining the geometry and effective length of the angle, applying an appropriate buckling equation, and converting the critical load to an allowable stress using a safety factor. It is important to consult relevant design codes and standards to ensure accurate and safe calculations.

- Q:Can steel angles be used as reinforcement in concrete slabs?

- Yes, steel angles can be used as reinforcement in concrete slabs. Steel angles provide additional strength and support to the concrete, helping to prevent cracking and increase the load-bearing capacity of the slab. They are commonly used in construction projects where enhanced structural integrity is required.

- Q:What are the different types of steel angles used in bridges?

- There are several different types of steel angles that are commonly used in bridges for various purposes. These include: 1. Equal Leg Angles: These angles have equal legs and are commonly used for structural support in bridge construction. They provide stability and strength to the bridge structure. 2. Unequal Leg Angles: As the name suggests, these angles have unequal legs and are used in situations where additional strength or specific load-bearing requirements are necessary. They are often used in combination with equal leg angles to provide support and distribute weight evenly. 3. L-Shaped Angles: L-shaped angles are used for various purposes in bridge construction, such as connecting beams and columns or providing additional support at connection points. They are often used in combination with other types of angles to create a sturdy and well-supported bridge structure. 4. Tapered Angles: Tapered angles are used in bridges where a change in width or height is required. These angles are often used in bridge piers or abutments to provide a smooth transition between different sections of the bridge. 5. Bent Angles: Bent angles are used in bridges where a specific angle is required to accommodate the design or alignment of the bridge. These angles are often custom-made to fit the specific needs of the bridge construction project. 6. Hollow Structural Section (HSS) Angles: HSS angles are hollow steel sections that are used in bridge construction to provide additional strength and reduce the weight of the structure. These angles are commonly used in situations where weight reduction is a priority, such as in long-span bridges or bridges with high load-bearing requirements. Each of these steel angles serves a specific purpose in bridge construction, and their selection depends on factors such as the design requirements, load-bearing capacity, and structural stability needed for the bridge.

- Q:How do you inspect and measure the dimensions of a steel angle?

- To inspect and measure the dimensions of a steel angle, the following steps can be followed: 1. Tools required for the task are a measuring tape or ruler, a protractor, and a square. 2. Begin by examining the length of the steel angle. Place one end of the measuring tape or ruler on one side of the angle and extend it to the opposite side. Make sure the measuring tape is straight and aligned with the edge of the angle. Read the measurement in inches or millimeters to determine the length. 3. Proceed to measure the width or thickness of the angle. Position the measuring tape or ruler perpendicular to the length of the angle and measure the distance between the two parallel sides. This will provide the width measurement. 4. To measure the height or depth of the angle, position the measuring tape or ruler perpendicular to the width measurement. Again, ensure that the measuring tape is aligned with the edge of the angle and measure the distance between the two sides. This will yield the height measurement. 5. To verify the accuracy of the angle being 90 degrees, employ a square. Place the square against one side of the angle and ensure alignment with the adjacent side. Check if the corner of the angle fits perfectly within the square. If it does, the angle is indeed 90 degrees. If not, adjustments may be necessary. 6. Lastly, if the angle of the steel angle needs measurement, a protractor can be employed. Align one side of the protractor with one side of the steel angle and observe where the other side intersects with the protractor scale. Read the angle measurement to determine the exact angle. By adhering to these steps and utilizing the appropriate tools, one can effectively inspect and measure the dimensions of a steel angle.

- Q:What are the different types of connections used for steel angles in industrial settings?

- In industrial settings, there are several types of connections used for steel angles depending on the specific application and structural requirements. Some of the commonly used connection types include: 1. Welded Connections: Welding is a popular method for connecting steel angles in industrial settings. It involves joining the angles using heat and pressure, resulting in a strong and durable connection. Welded connections are typically used when high strength and rigidity are required. 2. Bolting Connections: Bolts and nuts are used to connect steel angles in bolting connections. This type of connection allows for ease of assembly and disassembly, making it suitable for applications where flexibility and adjustability are important. Bolting connections can be easily tightened or loosened as needed. 3. Riveted Connections: Riveting involves using metal rivets to connect steel angles. This connection type offers good strength and stability and is commonly used in heavy-duty applications. Riveted connections require specialized equipment and skilled labor for installation and removal. 4. Adhesive Connections: Adhesives can also be used to bond steel angles together. This type of connection provides good load distribution and can be used in applications where welding or bolting is not feasible. Adhesive connections require proper surface preparation and adhesive selection to ensure adequate bonding strength. 5. Mechanical Connections: Mechanical connections such as cleats, brackets, plates, or clips can be used to connect steel angles. These connections provide flexibility and ease of installation, allowing for adjustments and modifications in the future if needed. It is important to note that the selection of the connection type depends on various factors such as the load-bearing capacity required, the structural design, safety considerations, and the specific environmental conditions in the industrial setting. Consulting with structural engineers and following industry standards and codes is crucial to ensure the appropriate type of connection is used for steel angles in industrial applications.

- Q:What are the different load-carrying capacities for steel angles?

- The load-carrying capacities for steel angles can vary depending on several factors such as the size and shape of the angle, the type of steel used, and the specific application or use case. Generally, load-carrying capacities for steel angles are determined by considering the maximum allowable stress or load that the angle can withstand without experiencing permanent deformation or failure. This is often expressed in terms of the maximum axial or bending load that an angle can support. To determine the load-carrying capacity of a specific steel angle, engineers and structural designers refer to industry standards and guidelines, such as the American Institute of Steel Construction (AISC) Manual of Steel Construction. These standards provide tables and formulas that take into account various factors such as the angle's dimensions, thickness, and moment of inertia to calculate its load-carrying capacity. It is important to note that load-carrying capacities for steel angles are typically specified for specific loading conditions and safety factors. These factors include the type of load (e.g., axial or bending), the direction and magnitude of the applied load, and the safety factor required to ensure the structural integrity and durability of the angle. Therefore, it is essential to consult the relevant codes, standards, and engineering resources to determine the specific load-carrying capacity of a particular steel angle for a given application. Professional structural engineers and designers are best equipped to assess and determine the load-carrying capacities of steel angles based on their expertise and familiarity with the applicable design codes and standards.

- Q:How do steel angles contribute to sustainable transportation infrastructure?

- Steel angles contribute to sustainable transportation infrastructure in several ways. Firstly, steel angles are commonly used in the construction of bridges and other transportation structures due to their high strength-to-weight ratio. This enables the creation of lighter, yet durable, structures that require less material and resources for construction. Additionally, steel angles are highly resistant to corrosion, reducing maintenance needs and increasing the lifespan of transportation infrastructure. This longevity reduces the need for frequent repairs or replacements, resulting in lower carbon emissions and reduced waste. Furthermore, steel angles can be easily recycled at the end of their life, promoting a circular economy and reducing the demand for new steel production. Overall, the use of steel angles in transportation infrastructure helps create sustainable and resilient systems that minimize environmental impacts and promote long-term sustainability.

- Q:What are the different types of steel angles connections?

- There are several different types of steel angle connections used in construction and engineering projects. Some of the most common types include: 1. Welded Connection: This is the most straightforward type of steel angle connection, where the angles are joined together using welding techniques. It provides a strong and rigid connection, but it requires skilled welders and can be time-consuming. 2. Bolted Connection: In this type of connection, the angles are connected by bolts, nuts, and washers. It allows for easier disassembly and modification, making it a popular choice for temporary structures or where future changes may be required. Bolted connections can be used with or without additional reinforcement, such as gussets or plates. 3. Riveted Connection: Riveting involves joining the angles using rivets, which are metal pins with a head on one end. Rivets are inserted into pre-drilled holes and then hammered to form a permanent connection. Although less common nowadays, riveted connections were widely used in older steel structures and bridges. 4. Clip Angle Connection: This type of connection involves using clip angles, which are small steel angles that are bolted or welded to the main angles. Clip angles provide additional support and reinforcement to the primary connection, enhancing its strength and stability. 5. Pinned Connection: Pinned connections allow for rotational movement between the angles, providing flexibility and allowing for load redistribution. They typically involve a pin or bolt passing through holes in the angles, allowing them to rotate freely. 6. Gusset Plate Connection: Gusset plates are flat steel plates that are used to connect and reinforce the angles. They are usually bolted or welded to the angles and provide additional strength and stability to the connection. The choice of steel angle connection depends on various factors such as the load-bearing requirements, structural design, ease of installation, and the need for future modifications. Each type has its advantages and disadvantages, and engineers select the most suitable connection type based on the specific project requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GB Standard Steel Angle Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords