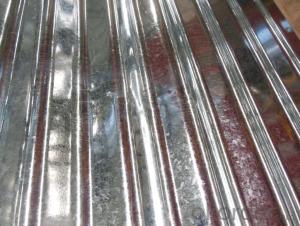

Galvanized Corrugated Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

- Q:What are the different grades of steel sheets available?

- There are several grades of steel sheets available, each with its own unique properties and uses. Some of the commonly used grades include: 1. Carbon Steel: This is the most common and widely used grade of steel sheet. It contains varying amounts of carbon and is known for its strength and durability. Carbon steel sheets are used in a wide range of applications, including construction, automotive, and manufacturing. 2. Stainless Steel: This grade of steel sheet contains high levels of chromium, which provides excellent corrosion resistance. Stainless steel sheets are commonly used in industries such as food processing, chemical, and medical, where resistance to corrosion is crucial. 3. Galvanized Steel: This type of steel sheet is coated with a layer of zinc to protect it from corrosion. Galvanized steel sheets are often used in outdoor applications, such as roofing, fences, and gutters, where exposure to moisture and the elements is common. 4. Alloy Steel: This grade of steel sheet is made by adding other elements, such as manganese, nickel, or chromium, to improve its mechanical properties. Alloy steel sheets are commonly used in applications that require high strength, such as construction equipment, aircraft parts, and machinery. 5. Tool Steel: This grade of steel sheet is designed to have high hardness and wear resistance, making it suitable for use in tools and dies. Tool steel sheets are commonly used in industries such as automotive, aerospace, and manufacturing. It's important to note that these are just some of the grades of steel sheets available, and there are many more specialized grades tailored for specific applications. The choice of grade depends on factors such as the required strength, corrosion resistance, and specific application requirements.

- Q:How do steel sheets perform in terms of electrical conductivity?

- Steel sheets are not good conductors of electricity compared to materials like copper or aluminum. While steel does conduct electricity, it has a relatively high resistance, which limits its ability to efficiently transmit electrical current.

- Q:What are the different types of steel sheet finishes for industrial applications?

- There are several types of steel sheet finishes commonly used in industrial applications, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q:Are steel sheets suitable for swimming pool construction?

- Yes, steel sheets are suitable for swimming pool construction. Steel sheets are known for their strength and durability, making them an excellent choice for building swimming pools. They provide a stable and sturdy structure that can withstand the weight of the water and the pressure exerted on the pool walls. Additionally, steel sheets can be easily molded and welded into various shapes and sizes, allowing for customization and flexibility in pool design. Moreover, steel is resistant to corrosion, which is crucial for maintaining the integrity of the pool over time, especially when exposed to chlorinated water. Therefore, steel sheets are a reliable and popular option for swimming pool construction.

- Q:How are steel sheets protected during cutting and fabrication?

- Steel sheets are protected during cutting and fabrication through various methods such as using protective coatings, applying lubricants, and utilizing automated cutting technologies. These measures help prevent corrosion, reduce friction, and ensure precise and efficient cutting without compromising the quality and integrity of the steel sheets.

- Q:Can steel sheets be formed into complex shapes?

- Yes, steel sheets can be formed into complex shapes through various processes such as bending, rolling, and pressing.

- Q:What is the cost of steel sheets compared to other materials?

- The cost of steel sheets typically varies depending on factors such as size, thickness, and specific type of steel. However, in general, steel sheets tend to be more affordable compared to other materials such as aluminum or titanium.

- Q:Can steel sheets be used for fire-rated doors?

- Yes, steel sheets can be used for fire-rated doors. Steel is a commonly used material for fire-rated doors due to its inherent fire-resistant properties and durability.

- Q:Can the steel sheets be cut easily?

- Yes, steel sheets can be cut easily with the right tools and techniques. Steel is a strong and durable material, but it can be cut using techniques such as shearing, sawing, or using plasma or laser cutting machines. The ease of cutting steel sheets also depends on their thickness and the specific type of steel being used. Thinner sheets are generally easier to cut than thicker ones. Additionally, using appropriate cutting tools and following proper safety measures can ensure a smooth and efficient cutting process.

- Q:What is the difference between galvanized and non-galvanized steel sheets?

- The main difference between galvanized and non-galvanized steel sheets is the presence of a protective zinc coating on the galvanized sheets. This coating helps to prevent corrosion and rusting, making galvanized steel sheets more durable and long-lasting compared to non-galvanized ones.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords