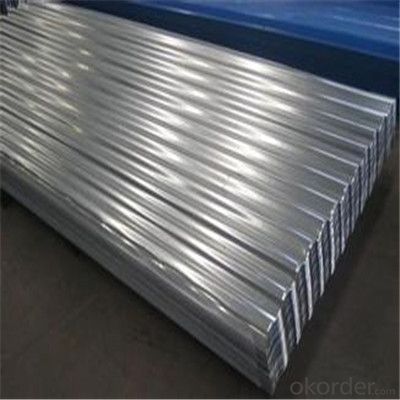

Galvanized Corrugated Iron Sheet for Roofing Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Corrugated Iron Sheet:

Smart appearance with subtle square fluting

Anti-capillary groove ensures leak-proof roof

Minimum yield strength of 550 MPa ensures required strength for roofing application

Accurate thickness, width and length gives a perfect fit for any roof

Wider valley ensures higher water discharge in case of heavy rains

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Raw material width 762mm, after corrugated width 665mm: 9 waves.

Raw material width 914mm ,after corrugated width 800mm:11 waves.

Raw material width 1000mm, after corrugated 890mm or 900mm :12 or 14 waves. as customer requirement

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:Can steel sheets be used for transportation equipment?

- Yes, steel sheets can be used for transportation equipment. Steel is a widely used material in the transportation industry due to its strength, durability, and cost-effectiveness. Steel sheets are commonly used in the construction of various transportation vehicles such as cars, trucks, buses, trains, ships, and airplanes. They can be used for the body panels, chassis, frames, and other structural components of these vehicles. Steel sheets offer excellent mechanical properties, including high tensile strength and impact resistance, making them suitable for withstanding the stresses and demands of transportation applications. Additionally, steel is also known for its ability to be easily formed and welded, allowing manufacturers to create complex shapes and structures required for transportation equipment.

- Q:Can steel sheets be used for outdoor sculptures?

- Yes, steel sheets can be used for outdoor sculptures. Steel is a durable and weather-resistant material, making it suitable for outdoor environments. Additionally, it can be shaped and welded to create intricate and unique sculptures.

- Q:Are steel sheets suitable for outdoor furniture?

- Yes, steel sheets are suitable for outdoor furniture. Steel is known for its durability, strength, and resistance to weather and corrosion, making it an ideal material for outdoor use. Additionally, steel sheets can be easily shaped and welded to create various designs, making them versatile for different styles of outdoor furniture.

- Q:How is the quality of steel sheets determined?

- Several factors and tests determine the quality of steel sheets. The chemical composition of the steel is a primary factor, including the presence and percentage of elements such as carbon, manganese, silicon, and alloying elements like chromium, nickel, and molybdenum. The specific composition impacts the steel's strength, durability, and resistance to corrosion. The mechanical properties of the steel are also important, assessed through tests like tensile strength, yield strength, elongation, hardness, and impact resistance. These tests determine the steel's ability to withstand forces and deformation without failure. Surface quality plays a crucial role as well. The surface must be defect-free, without cracks, scratches, pits, or any irregularities that could affect performance or appearance. Thickness and uniformity are crucial factors too. Thickness is measured using methods like ultrasonic gauges or micrometers to ensure compliance with specifications. Deviations from the required thickness can impact structural integrity and performance. Weldability, formability, and machinability are also tested, determining suitability for specific applications. These tests evaluate the steel's behavior during fabrication processes like welding, bending, or machining. Overall, the quality of steel sheets is determined through a comprehensive evaluation of their chemical composition, mechanical properties, surface quality, thickness, and other performance characteristics. These assessments ensure compliance with standards and suitability for intended applications.

- Q:What is the maximum load-bearing capacity of steel sheets?

- The maximum load-bearing capacity of steel sheets depends on various factors such as the thickness, grade, and type of steel, as well as the specific application and support structure. Generally, steel sheets have high load-bearing capacities ranging from a few thousand pounds to several hundred thousand pounds per square inch, making them suitable for a wide range of structural and industrial applications.

- Q:What are the different types of steel sheet coatings available?

- There are several types of steel sheet coatings available, including galvanized, galvalume, tinplate, and stainless steel coatings. Each type offers different properties and advantages depending on the specific application and requirements. Galvanized coatings provide excellent corrosion resistance, galvalume coatings offer enhanced durability and heat reflectivity, tinplate coatings provide superior solderability and food-grade suitability, while stainless steel coatings offer exceptional resistance to corrosion, heat, and staining. The choice of coating depends on factors such as the environment, intended use, and desired performance of the steel sheet.

- Q:How do steel sheets perform in flexural strength?

- Steel sheets have excellent flexural strength, meaning they are able to withstand and resist bending or deformation under applied loads. Due to their inherent stiffness and high tensile strength, steel sheets exhibit exceptional performance in flexural applications, making them a preferred choice in various industries such as construction, automotive, and manufacturing.

- Q:Are steel sheets resistant to scratching or abrasion?

- Yes, steel sheets are generally resistant to scratching and abrasion due to their high strength and durability. However, the degree of resistance may vary depending on the specific type of steel and the conditions in which it is used.

- Q:What are the different types of steel sheet surface coatings for corrosion resistance?

- There are several types of steel sheet surface coatings available for corrosion resistance, including galvanized coatings, zinc-rich coatings, aluminum coatings, and organic coatings such as paint or epoxy. Each coating offers unique benefits and application suitability depending on the specific requirements and environmental conditions.

- Q:What is the average lead time for manufacturing steel sheets?

- The average lead time for manufacturing steel sheets can vary depending on various factors such as the size and complexity of the order, the manufacturing process employed, and the current demand and capacity of the steel sheet production facility. However, in general, the average lead time for manufacturing steel sheets can range from a few weeks to a few months. If the order is relatively small and standard in size, the lead time may be shorter, typically ranging from 2 to 6 weeks. This time frame allows for the procurement of raw materials, processing, and quality control procedures to ensure the final product meets the required specifications. On the other hand, if the order is larger or involves more complex specifications, the lead time may be longer. This is because additional time may be required for customizing the steel sheets according to specific dimensions, finishes, or treatments. In such cases, the lead time can extend to several months. It is important to note that lead times can also be influenced by external factors such as supply chain disruptions, unforeseen delays in raw material procurement, or fluctuations in demand. Therefore, it is always advisable to consult with the steel sheet manufacturer or supplier for an accurate estimate of the lead time based on the specific requirements of the order.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000345 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords