Galvanized Color Coated Plate Roofing Sheet PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Galvanized Color Coated Plate Roofing Sheet PPGI

Details of Galvanized Color Coated Plate Roofing Sheet PPGI

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Specification of Galvanized Color Coated Plate Roofing Sheet PPGI

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

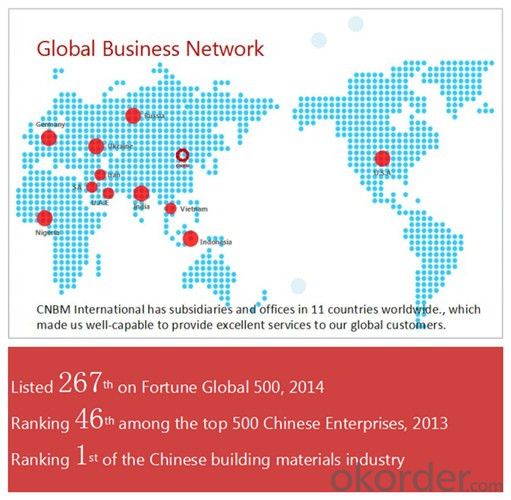

CNBM Introduction of Galvanized Color Coated Plate Roofing Sheet PPGI

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Galvanized Color Coated Plate Roofing Sheet PPGI

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

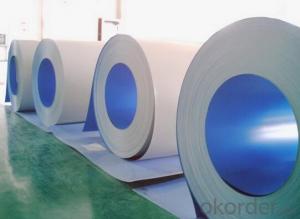

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the properties of mold steel?

- Mold steel possesses several properties that make it ideal for use in mold making. It typically has high hardness, excellent wear resistance, and good toughness. Mold steel also exhibits good machinability, allowing for intricate mold designs to be easily achieved. Additionally, it has good thermal conductivity, which aids in efficient cooling during the molding process. Overall, the properties of mold steel enable it to withstand the high pressures and temperatures involved in molding, ensuring durability and longevity of the molds.

- Q:What are the properties of magnetic steel?

- Magnetic steel is characterized by its ability to attract and hold a magnetic field. It has a high magnetic permeability, allowing it to easily magnetize and demagnetize. Magnetic steel also exhibits high coercivity, meaning it has a strong resistance to losing its magnetization. Additionally, it possesses high electrical conductivity and is often used in various applications such as transformers, motors, and magnetic storage devices.

- Q:Can special steel be used in the production of fasteners?

- Yes, special steel can be used in the production of fasteners. Special steel, such as alloy steel or stainless steel, offers enhanced strength, corrosion resistance, and durability, making it suitable for various fastening applications. Its unique properties ensure reliable and long-lasting connections in industries like automotive, construction, and aerospace.

- Q:What are the applications of special steel in the aerospace sector?

- Due to its exceptional properties and capabilities, special steel finds numerous applications in the aerospace sector. Firstly, it is utilized in the manufacturing of aircraft engines. Special steel's high strength and temperature resistance make it an ideal choice for components such as turbine blades and discs, which experience extreme heat and stress during operation. Moreover, special steel provides excellent corrosion resistance, ensuring the durability and reliability of vital engine parts. Another important application of special steel in the aerospace sector involves constructing aircraft structures. Special steel alloys are employed to fabricate landing gear, wing components, and other structural elements. The high strength-to-weight ratio of special steel enables the production of lightweight yet sturdy structures, contributing to fuel efficiency and overall performance. Special steel is also essential in producing aerospace fasteners, including bolts, nuts, and screws that secure various aircraft components together. Special steel's exceptional mechanical properties, fatigue resistance, and vibration resistance make it an ideal material for fasteners, ensuring the integrity and safety of aircraft assemblies. Furthermore, special steel is utilized in aerospace tooling and equipment. Tools used in the manufacturing process, such as cutting tools and molds, are often made from special steel. Its high hardness and wear resistance enable efficient and precise machining of aerospace components. Additionally, special steel is employed in the production of specialized equipment, such as test rigs, calibration devices, and ground support equipment, which are crucial for aerospace operations and maintenance. In conclusion, special steel plays a crucial role in the aerospace sector, contributing to the overall safety, performance, and reliability of aerospace systems. Its use in aircraft engines, structures, fasteners, and tooling is indispensable for the demanding and critical applications within the aerospace industry, thanks to its unique properties.

- Q:How does special steel perform in terms of thermal expansion?

- Special steel typically performs well in terms of thermal expansion. It has a low coefficient of thermal expansion, meaning it expands and contracts less with temperature changes compared to other types of steel. This makes it more dimensionally stable and less prone to warping or distortion when exposed to heat or cold.

- Q:How does special steel perform in oil and gas applications?

- Special steel is highly desirable and widely used in oil and gas applications due to its exceptional performance and superior properties. Special steel exhibits excellent resistance to corrosion, which is crucial in environments where oil and gas are present. This resistance to corrosion helps prevent equipment failure and ensures the longevity and reliability of the components. Moreover, special steel possesses high strength and durability, making it suitable for withstanding extreme conditions, such as high pressure and temperature. This strength allows the steel to withstand the demanding and harsh environments that oil and gas applications often present. Additionally, special steel can retain its mechanical properties even at elevated temperatures, providing stability and reliability in these challenging conditions. Another significant advantage of special steel is its excellent weldability. This property allows for easy fabrication and assembly of components, reducing production time and costs. It also ensures the integrity of the structures and equipment used in oil and gas applications. Furthermore, special steel offers exceptional resistance to fatigue and wear, which are common concerns in oil and gas operations. The ability of special steel to withstand cyclic loading and abrasive conditions ensures the longevity and reliability of the components, reducing maintenance and replacement costs. Overall, special steel performs exceptionally well in oil and gas applications due to its corrosion resistance, high strength, durability, weldability, and resistance to fatigue and wear. Its superior properties make it a preferred choice for critical components, ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q:Can special steel be used in the paper manufacturing industry?

- Yes, special steel can be used in the paper manufacturing industry. Special steel, such as stainless steel or corrosion-resistant steel, can be utilized in various applications within the paper manufacturing process, including equipment like rollers, blades, and drying cylinders. These types of steel offer durability, resistance to corrosion, and high strength, making them suitable for handling the demanding conditions and requirements of the paper manufacturing industry.

- Q:How is special steel used in the telecommunications supply chain?

- Special steel is used in the telecommunications supply chain for a variety of applications. It is commonly used in the manufacturing of telecommunication towers, antennas, and satellite dishes due to its high strength and durability. Special steel is also utilized in the production of transmission lines, cables, and connectors, where its corrosion resistance and electrical conductivity properties are essential. Additionally, special steel is employed in the fabrication of equipment racks, cabinets, and enclosures, providing a sturdy and secure housing for telecommunication devices. Overall, special steel plays a crucial role in ensuring the reliability and performance of telecommunications infrastructure.

- Q:How does cryogenic treatment affect the toughness of special steel?

- Cryogenic treatment has a significant impact on the toughness of special steel. It involves subjecting the steel to extremely low temperatures, typically below -150 degrees Celsius, for an extended period. This process transforms the microstructure of the steel, resulting in improved mechanical properties, including increased toughness. During cryogenic treatment, the steel undergoes a process called martensitic transformation, where the carbon atoms in the steel lattice rearrange themselves. This transformation leads to the formation of additional carbides, which are responsible for strengthening the steel and increasing its toughness. These carbides act as barriers, impeding the propagation of cracks and enhancing the resistance of the steel to fracture. Furthermore, cryogenic treatment also reduces the presence of retained austenite, a metastable phase in steel that can negatively impact its mechanical properties. The transformation of retained austenite into martensite during cryogenic treatment further improves the toughness of the steel. The increased toughness of cryogenically treated special steel makes it suitable for various applications that require high strength and resistance to fracture. It enhances the steel's ability to withstand heavy loads, impacts, and harsh environments. Additionally, cryogenic treatment can improve the wear resistance and dimensional stability of special steel. It is important to note that while cryogenic treatment can significantly enhance the toughness of special steel, it is not a standalone solution. Other factors, such as the initial composition and heat treatment of the steel, also play a crucial role in determining its overall mechanical properties. Therefore, cryogenic treatment should be considered as a complementary process to optimize the toughness of special steel.

- Q:How is special steel used in the construction manufacturing process?

- Special steel is used in the construction manufacturing process due to its unique properties and characteristics. It is commonly utilized in the production of structural components, such as beams, columns, and reinforcements, where high strength, durability, and resistance to corrosion are crucial. Special steel also finds application in the manufacturing of machinery, equipment, and tools used in construction, thanks to its ability to withstand heavy loads and extreme conditions. Additionally, it is used for specialized purposes like in the construction of bridges, skyscrapers, and other architectural marvels, where its exceptional strength and reliability are essential for ensuring the safety and longevity of the structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Color Coated Plate Roofing Sheet PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords