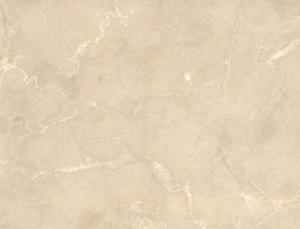

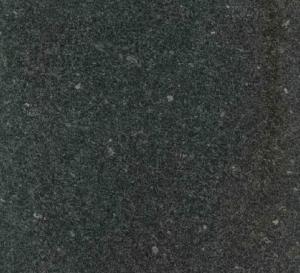

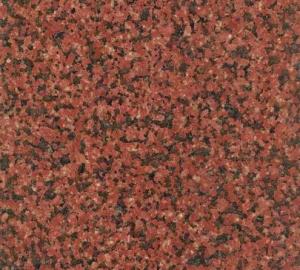

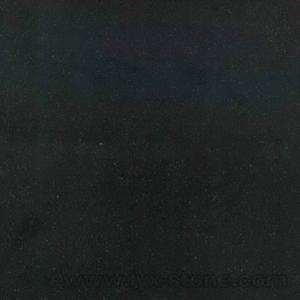

G355 Natural stone from Xiamen for exporting

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Natural Granite Interior Wall Wtone Decoration CHINESE GRANITE STONE | |||

Colors | Yellow,Pink,Grey,Dark,White,Green,Blue,Red,Brown etc . | ||

Finished | Polished,honed,flamed,bushhammered,sandblasted, chiseled, natural split,tumbled,pineapple,etc. | ||

Production | tile,slab,kerbstone,cube stone, paving stone, countertop. | ||

Dimension | Slabs | 600upx1800upx20~30mm | |

700upx1800upx20~30mm | |||

1200upx2400~3200upx20~30mm | |||

Tiles

| 305x305mm(12"x12") | ||

300x600mm(12"x24") | |||

400x400mm(18"x18") | |||

600x600mm(24"x24") | |||

Steps

| Stair: (90-180) x 30/32/33/35 | ||

Riser: (90-180) x14/15/16/17 | |||

Thickness | 10mm(3/8"),12mm(1/2"),20mm(3/4"),etc. | ||

Also Available | According to your requirement | ||

Packaging Details | Strong fumigated wooden pallets for export. | ||

Delivery Time | According to your purchase quantity. | ||

M.O.Q. | One 20' Container | ||

Quality Assurance | During the whole production process, from raw material choosing, fabrication to package, Our quality controller will strictly inspect each pcs and control each process to ensure quality standards and timely delivery. | ||

| |||

- Q:Granite Marble with what medicine is polished

- 1, the construction process: stone surface finish surface cleaning → stone gap marble glue repair → overall ground grinding 6-7 times → ground drying → ground crystal treatment (K2, K3 syrup) → overall ground conservation (K1 syrup) → ground Clean up. 2, the stone surface to complete the surface clean up: the stone before the crystallization of the ground processing, paving finish the overall surface formation, no color, each stone between the diagonal flush, the ground to clean up the whole, with dry and clean to drag clean, No sand on the ground, impurities. 3, stone gap marble glue repair: stone surface after the completion of the overall clean-up, with marble glue on each piece of stone above the small spots to repair, first of all the original damaged surface with the stone color of the marble glue to repair. And then use a special stone sewing machine on the original stone installation of the seam in the re-neat cutting slit, so that the width of the gap changed almost, and then close to the stone color of the marble glue to fill it (Note: If the past has been done in the seam Processing without the need for new openings). Venom glue must be repaired after the glue can be done under the next process.

- Q:How to distinguish between type I and S granite

- The difference between type I and S granites is that they form different source rocks. I type granite (I type granite) is a series of quasi-aluminum calcium alkaline granite rock in general, mainly a variety of British cloud diorite to granite diorite and granite. The granite source rock material is not the weathering of the igneous rock melting, is the product of the continental edge of the event, referred to as I-type granite. S-type granite (S type granite) is a source of sediment to the source rock, after part of the melting and crystallization of granite. Granite (Granite), the main component of the continental crust, is a kind of magma in the surface below the formation of igneous rock [1], belonging to the deep intrusive rocks. Mainly in the form of minerals such as quartz or feldspar. The granite language is the Latin granum, meaning grain or grain. Because granite is a deep diagenetic, often able to form a well-developed, visually discernible mineral particles, hence the name. Granite is not easy to weathering, beautiful color, the appearance of color can be maintained for more than a century, because of its high hardness, wear resistance, in addition to the use of high-level architectural decoration works, hall floor, or open-air carving of the preferred material.

- Q:How to identify strong weathering granite and granite granite?

- Mainly to combine the experience of the region to determine the site construction are not allowed to eat, it is best to ask the investigators to do this work. In general, most of the strong weathered rock structure is damaged, the mineral composition changes significantly, the rock mass is broken, the hopper can be excavated, and the structure of the weathered rock is partially broken, the weathering fissure develops, the rock is cut into rock blocks,

- Q:What is the hardness range of granite?

- The granite has a specific gravity of between 2.63 and 2.75 and has a compressive strength of 1,050 to 14,000 kg / cm2 (15,000 to 20,000 pounds per square inch) because the strength of the granite is greater than that of sandstone, limestone and marble. Granite formation of the special conditions and firm structural characteristics, it has the following unique performance: (1) has a good decorative performance, applicable to public places and outdoor decoration. (2) with excellent processing performance: saw, cut, polished, drilling, sculpture, etc. Its processing accuracy of up to 0.5μm below the luminosity of more than 1600. (3) wear resistance is good, 5-10 times higher than cast iron. (4) thermal expansion coefficient is small, not easy to deformation, and indium steel is similar to the temperature affected by minimal. (5) elastic modulus, higher than cast iron. (6) Rigid, internal damping coefficient, 15 times larger than steel. Can shock, shock. (7) granite with brittle, damaged only partial loss, does not affect the overall straightness. (8) granite chemical stability, not easy weathering, acid, alkali and corrosive gas erosion, the chemical and silica content is proportional to the service life of up to 200 years. (9) granite with non-conductive, non-magnetic, field stability.

- Q:Dry hanging granite how many square meters

- Granite, the main component of the continental crust, is a kind of magma formed in the surface below the formation of igneous rocks [1], the main components of feldspar, mica and quartz. The granite language is the Latin granum, meaning grain or grain. Because granite is a deep diagenetic, often able to form a well-developed, visually discernible mineral particles, hence the name. Granite is not easy to weathering, beautiful color, the appearance of color can be maintained for more than a century, because of its high hardness, wear resistance, in addition to the use of high-level architectural decoration works, hall floor, or open-air carving of the preferred material.

- Q:The same grade of marble and granite that expensive?

- The same grade of marble and granite compared to granite, because the granite corrosion resistance and weathering resistance is much stronger than the marble.

- Q:How to maintain the granite

- The daily protection of granite floors should be cleaned daily with dust. Weekly maintenance to spray maintenance is appropriate, you can 1-2 times per week with a heavy machine, red pad and granite crystal agent for jet maintenance. Spraying maintenance operation can be the amount of granite crystal brightener sprayed on the ground, each working area to 1-2 square meters is appropriate, when the grinding machine needs to be evenly filled with brightener, fine polishing to bright. Weekly maintenance can also use steel wool on the ground polishing, it should be noted that the steel wool should be kept clean, if found to be timely replacement or treatment of dirt. In case of light-colored granite ground, it should be switched to red polishing pad to prevent steel wool from getting black and making light-colored granite contaminated.

- Q:What is the density of granite?

- The granite language is the Latin granum, meaning grain or grain. Because granite is a deep diagenetic, often able to form a well-developed, visually discernible mineral particles, hence the name. Granite is not easy to weathering, beautiful color, the appearance of color can be maintained for more than a century, because of its high hardness, wear resistance, in addition to the use of high-level architectural decoration works, hall floor, or open-air carving of the preferred material.

- Q:What is the lychee panel in the granite?

- Granite fire board processing methods, involving granite processing technology. First, the natural granite saw the plate, the surface of the plate after the initial grinding, and then the original grinding surface flame burning, leaving it off 0.5 to 1 mm surface layer. The granite material processed by this method exposes the stone character, which is simple, rough and strong. Granite fire boards can be used on sidewalks, highways, indoor floors and walls. The following are the same as the " With liquefied gas and oxygen through the high temperature flame burned, due to uneven heating different expansion, and the formation of the same effect as litchi surface, a non-slip effect.

- Q:What can granite do

- Large grain rolling into gravel, is an excellent aggregate of concrete.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

G355 Natural stone from Xiamen for exporting

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords