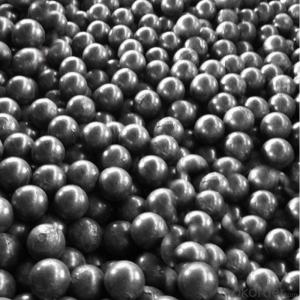

G10-G120 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Product Description:

1.18 years on metal abrasives manufacturing and exporting.

2. Delivery within 15 days.

3. Full transport insurance.

4. Sell to 32 countries on 5 continents.

Product Picture:

Size:

S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Chemistry Composition:

| C | Mn | Si | S | P |

| 0.70-1.20% | 0.60-1.20% | 0.40-1.20% | ≤0.05% | ≤0.05% |

Average degree of hardness:

| Normal | 40-50HRC (377-509HV) |

| Special | 52-56HRC (543-620HV) |

| Special | 56-60HRC (620-713HV) |

| Minimum density | 7.4g/cm3 |

Package:

25kgs/bag, 40bags/ton/pallet

1000kgs/ton bag

Product Standard:

SAE J827

We press American Cast steel association strictly"SFSA20-66 The Cast steel whets to anticipate the standard", American automobile engineer's association"SAE J1993Cast Steel GritThe standard", the People's Republic of China black metallurgy profession"YB/T5150-1993Cast Steel GritThe standard", the American soldier mark"MIL-S -851CTidy up and enhance to use the metals steel sand and the steel pill"and the nations standardize organization" ISO11124-3High carbon Cast steel pillCast Steel Grit Standard"the future life produce.

Product use:

Cast steel shot is wildly used for cleaning the rust of metal surface and the reinforced of metal parts. Such as Foundry Industry, Shipbuilding Industry, Container Industry, Marble Cutting, Petroleum Pipeline, Automotive Industry etc.

- Q:How is steel used in the manufacturing of HVAC systems?

- Steel is commonly used in the manufacturing of HVAC systems for its strength, durability, and ability to withstand high temperatures. It is used in various components such as air ducts, heat exchangers, and furnace enclosures, ensuring the system's structural integrity and longevity.

- Q:How does steel sheet metal fabrication work?

- Steel sheet metal fabrication is the process of transforming flat steel sheets into various shapes and structures through cutting, forming, and assembling. It typically involves steps such as cutting the sheet into the desired size, shaping it through bending or rolling, joining multiple pieces through welding or fastening, and adding finishing touches like painting or coating. This precise and intricate process allows for the creation of a wide range of products, from simple brackets to complex machinery components, by utilizing the versatility and strength of steel.

- Q:What are the uses of steel in the construction of schools and universities?

- Steel is widely used in the construction of schools and universities due to its superior strength and durability. It is commonly used in structural components like beams, columns, and frames, providing stability and support to the buildings. Additionally, steel is fire-resistant, making it a safe choice for educational facilities. Its versatility allows for flexible designs, accommodating various architectural styles and adapting to changing needs. Moreover, steel construction is efficient, reducing construction time and costs, while also being environmentally friendly as it is recyclable. Overall, steel plays a crucial role in ensuring the safety, longevity, and functionality of schools and universities.

- Q:What are the advantages of using steel in the construction of sports stadiums?

- There are several advantages of using steel in the construction of sports stadiums. Firstly, steel is a durable and strong material, which provides the necessary structural integrity and stability required for large-scale constructions like stadiums. Secondly, steel is highly versatile and allows for creative and innovative architectural designs. It can be easily shaped and manipulated to create unique and visually appealing structures. Additionally, steel is a cost-effective option as it is readily available and can be prefabricated off-site, reducing construction time and labor costs. Lastly, steel is also a sustainable choice as it is recyclable, minimizing waste and environmental impact.

- Q:How is steel used in the railway industry?

- Steel is used extensively in the railway industry for various purposes. It is used to manufacture rails, which form the tracks on which trains run. Steel is also used to construct train cars, locomotives, and various components such as wheels, axles, and couplers. Additionally, steel is utilized in the construction of bridges and tunnels, ensuring the safety and stability of railway infrastructure.

- Q:What are the different types of steel chains and their uses in lifting equipment?

- There are primarily three types of steel chains used in lifting equipment: alloy steel chains, carbon steel chains, and stainless steel chains. Alloy steel chains are incredibly strong and durable, making them suitable for heavy-duty lifting applications. Carbon steel chains are more affordable and offer decent strength, making them commonly used in medium-duty lifting tasks. Lastly, stainless steel chains are corrosion-resistant and often used in industries where exposure to moisture or chemicals is expected. Each type of steel chain has distinct properties that make them suitable for specific lifting needs.

- Q:What are the common uses of steel in the telecommunications industry?

- In the telecommunications industry, steel is commonly used for the construction of telecommunication towers and antennas. The high strength and durability of steel make it an ideal material for supporting heavy equipment and withstanding harsh weather conditions. Additionally, steel is often utilized in the manufacturing of various infrastructure components such as cabinets, racks, and enclosures, providing protection and stability to sensitive telecommunications equipment.

- Q:What are the advantages of using steel over other materials like aluminum or plastic?

- There are several advantages of using steel over other materials like aluminum or plastic. Firstly, steel is known for its superior strength and durability, making it highly resistant to impact, heat, and extreme weather conditions. This makes it ideal for applications that require high structural integrity and longevity. Secondly, steel possesses excellent load-bearing capabilities, allowing it to support heavy loads without deformation or failure. This property makes it suitable for constructing large-scale structures such as bridges, skyscrapers, and industrial buildings. Moreover, steel is a highly recyclable material, which contributes to its sustainability and reduced environmental impact. It can be melted down and reused countless times without losing its properties, making it an eco-friendly choice. Additionally, steel offers a wide range of design possibilities due to its versatility and malleability. It can be easily shaped, bent, and welded, allowing for complex and intricate designs that are difficult to achieve with other materials. Lastly, steel has excellent fire resistance properties, making it a preferred choice in industries where fire safety is crucial, such as construction and transportation. Overall, the advantages of steel, including its strength, durability, recyclability, versatility, and fire resistance, make it a reliable and cost-effective choice over other materials like aluminum or plastic in many applications.

- Q:How does steel pipe coating for marine applications work?

- Steel pipe coating for marine applications works by applying a protective layer of coating to the surface of the steel pipe to prevent corrosion and extend its lifespan. The coating acts as a barrier against harsh marine environments, preventing the pipe from being exposed to corrosive elements such as saltwater and chemicals. This coating can be achieved through various methods such as fusion bonded epoxy (FBE), polyethylene (PE), or polypropylene (PP) coatings. These coatings provide excellent adhesion to the steel surface, ensuring long-term protection against corrosion, abrasion, and mechanical damage. Additionally, the coating also enhances the pipe's resistance to UV radiation and provides insulation against temperature fluctuations.

- Q:How is steel used in the construction of wastewater treatment plants?

- Steel is commonly used in the construction of wastewater treatment plants for various purposes such as structural support, tanks, pipelines, and equipment. It provides durability, strength, and corrosion resistance, ensuring the longevity and reliability of the facility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

G10-G120 Steel Shot with ISO9001 & SAE Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords