FRP Molded Grating /GRP Grating / FRP Grating on Best Sales with All kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

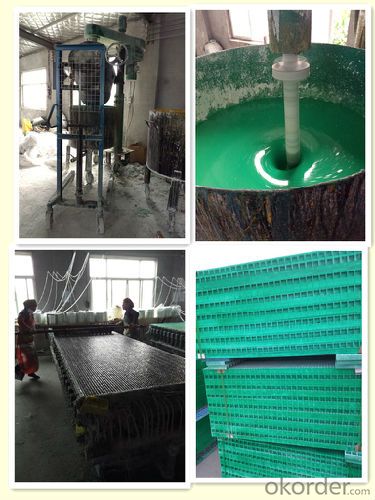

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles resistant to vibration or shock?

- FRP pultrusion profiles exhibit high resistance to both vibration and shock. Their exceptional properties, inherent in FRP materials, make them an ideal choice for applications that demand durability and strength in the face of dynamic loading conditions. The composition of FRP profiles typically entails a combination of reinforcing fibers and a resin matrix, resulting in superb stiffness and damping characteristics. As a result, FRP pultrusion profiles effectively absorb and dissipate vibrations and shock forces, effectively preventing damage or degradation. Moreover, the design flexibility of FRP enables tailored reinforcement and optimization, further bolstering their ability to withstand vibration and shock. Consequently, FRP pultrusion profiles prove to be a dependable option for industries such as aerospace, automotive, marine, and structural engineering, where these properties are of utmost importance.

- Q:Can FRP pultrusion profiles be used in the construction of water slides?

- Water slides can indeed utilize FRP pultrusion profiles. FRP, which stands for Fiber Reinforced Polymer, is a composite material that offers numerous advantages in the construction of water slides. To begin with, FRP pultrusion profiles possess a remarkable combination of lightweight construction and remarkable strength, making them an ideal choice for creating the structural components of water slides. These profiles boast impressive strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the overall structure. Moreover, FRP pultrusion profiles exhibit exceptional resistance to corrosion, which is of utmost importance in water slide construction. Given that water slides are constantly exposed to water, chemicals, and harsh weather conditions, traditional materials like steel tend to corrode and deteriorate over time. In contrast, FRP profiles are inherently corrosion-resistant, guaranteeing the longevity and durability of the water slide. Furthermore, FRP pultrusion profiles offer an abundance of design flexibility. They can be tailored to various shapes and sizes, enabling the creation of unique and thrilling water slide designs. These profiles are also easily moldable, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles possess exceptional thermal insulation properties. This proves advantageous for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. Such a feature enhances the comfort and enjoyment of users while simultaneously reducing energy consumption for heating or cooling the water. In summary, FRP pultrusion profiles are perfectly suited for water slide construction due to their lightweight nature, impressive strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q:Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q:Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical or telecommunications applications. FRP pultrusion profiles are known for their excellent electrical insulating properties, high strength-to-weight ratio, and corrosion resistance. These characteristics make them suitable for various electrical and telecommunications applications. In electrical applications, FRP pultrusion profiles can be used as electrical insulators, cable trays, busbar supports, and electrical enclosures. They provide insulation and protection against electrical shocks and are often chosen as an alternative to traditional materials like metal or wood due to their non-conductive properties. Additionally, FRP pultrusion profiles are lightweight and easy to install, which further adds to their suitability in electrical applications. In telecommunications applications, FRP pultrusion profiles are used for cable management systems, antenna supports, and equipment enclosures. Similar to electrical applications, the non-conductive nature of FRP pultrusion profiles ensures the safety and reliability of the telecommunications infrastructure. The profiles can also be customized to meet specific design requirements, such as incorporating cable routing channels or mounting brackets for equipment. Furthermore, FRP pultrusion profiles offer excellent resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them ideal for outdoor electrical or telecommunications installations, where exposure to these elements is common. Overall, FRP pultrusion profiles have proven to be a reliable and cost-effective choice for electrical and telecommunications applications, providing insulation, strength, durability, and resistance to environmental factors.

- Q:Are FRP pultrusion profiles resistant to high winds or hurricanes?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to high winds and hurricanes. FRP is a composite material that combines the strength of fiberglass with the durability of polymers. This results in a lightweight yet incredibly strong material that can withstand extreme weather conditions. FRP pultrusion profiles have been extensively tested and have proven to have excellent wind resistance properties. They have a high stiffness-to-weight ratio, allowing them to withstand the forces exerted by high winds without bending or breaking. Additionally, the inherent flexibility of FRP allows it to absorb and distribute the forces exerted by wind, reducing the risk of damage. In the case of hurricanes, FRP pultrusion profiles have demonstrated their ability to withstand the strong winds and flying debris associated with these severe weather events. They have been used in various applications such as building facades, bridges, and utility poles in hurricane-prone areas, with great success. Furthermore, FRP pultrusion profiles are corrosion-resistant, which is another advantage when it comes to withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or rot when exposed to moisture, making them even more suitable for these challenging weather conditions. Overall, due to their high strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications where resistance to high winds or hurricanes is required.

- Q:Are FRP pultrusion profiles resistant to hydraulic oils?

- Yes, FRP pultrusion profiles are generally resistant to hydraulic oils. The combination of fiberglass reinforcement and resin matrix used in pultrusion manufacturing makes these profiles highly resistant to various chemicals, including hydraulic oils. However, it is recommended to consult the specific resin manufacturer or supplier for detailed information on the compatibility of their FRP pultrusion profiles with different types of hydraulic oils.

- Q:Can FRP pultrusion profiles be used for structural applications?

- Certainly, FRP pultrusion profiles can be utilized for structural purposes. The process of pultrusion involves pulling fiber reinforcements through a resin bath and a heated die to cure the resin, resulting in robust, lightweight, and corrosion-resistant profiles with exceptional mechanical properties. The high strength-to-weight ratio of FRP pultrusion profiles makes them widely employed in different structural applications. These profiles can be engineered to possess specific load-bearing capacities, stiffness, and durability, making them suitable for a wide range of structural requirements. FRP pultrusion profiles find common use in various structural applications such as bridges, walkways, platforms, handrails, supports, beams, columns, and reinforcements in concrete structures. They are particularly advantageous in situations where traditional materials like steel or wood are unsuitable due to concerns regarding corrosion, electrical conductivity, or weight. The benefits of FRP pultrusion profiles are numerous. They are lightweight, making them easy to handle and transport. Furthermore, they exhibit resistance to corrosion, chemicals, and UV radiation, ensuring long-term durability even in harsh environments. Additionally, they possess excellent dimensional stability, remaining unaffected by warping, twisting, or shrinking over time. To summarize, FRP pultrusion profiles are highly suitable for structural applications owing to their strength, lightweight nature, corrosion resistance, and durability. They provide a cost-effective alternative to traditional materials while delivering superior performance in various structural projects.

- Q:Are FRP pultrusion profiles resistant to chemicals used in oil refineries?

- Yes, FRP pultrusion profiles are highly resistant to chemicals used in oil refineries. The combination of their fiberglass reinforcement and resin matrix makes them impervious to many corrosive substances, ensuring long-term durability and performance in such harsh environments.

- Q:Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Yes, FRP pultrusion profiles can be used in wastewater treatment facilities. FRP (Fiber Reinforced Plastic) pultrusion profiles are known for their high strength, corrosion resistance, and durability, making them suitable for various applications, including in harsh environments like wastewater treatment facilities. These profiles can be used for constructing structures, such as walkways, handrails, grating, and tanks, as well as for reinforcing or replacing traditional materials, such as steel or concrete, in different components of the facility. The corrosion resistance of FRP pultrusion profiles ensures their longevity and reduces maintenance costs, making them a viable option for wastewater treatment facilities.

- Q:Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Molded Grating /GRP Grating / FRP Grating on Best Sales with All kinds of Colors

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords