Forming Machine for Prestressed Hollow Core Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forming Machine for Prestressed Hollow Core Panels

1. Structure of Forming Machine for Prestressed Hollow Core Panels:

Forming Machine for Prestressed Hollow Core Panel works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Forming Machine for Prestressed Hollow Core Panels:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Forming Machine for Prestressed Hollow Core Panels Images:

4. Forming Machine for Prestressed Hollow Core Panels Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

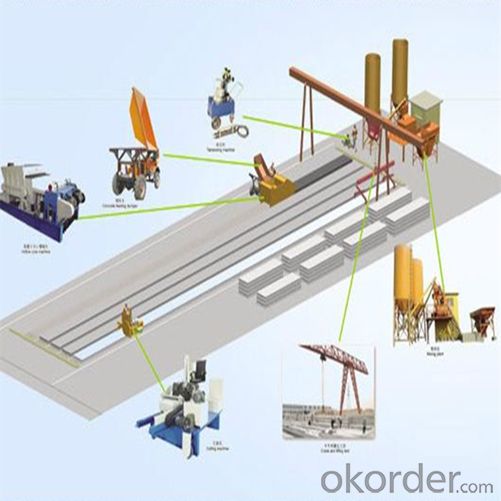

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q:What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- At present, other countries in the world, including international organizations, have not put forward the concept of equipment manufacturing. The concept of equipment manufacturing industry is unique to our country. Its formal appearance was seen in the central economic work conference in 1998, which explicitly stated: "we must energetically develop the equipment manufacturing industry."". (central economic work conference: Economic Daily, December 10, 1998, first edition) The core of the manufacturing industry is equipment manufacturing. People do not have the same understanding of equipment manufacturing industry, and there is no consensus definition and scope definition. It is generally believed that the manufacturing sector consists of the equipment manufacturing industry and the final consumer goods manufacturing industry. Equipment manufacturing industry is the general term of the industry which provides the production technology and equipment for the simple reproduction and extended reproduction of the national economy, namely the machine manufacturing industry for producing machines".

- Q:What are the mixing arms of the concrete mixer?

- Concrete mixer parts often due to operational mistakes and equipment damage, we should know that the correct use of Yantai mixer parts, mixing arm not only can complete the "workload" on time, but also to extend the service life

- Q:What is the difference and connection between equipment manufacturing and machine building?

- In accordance with the standards of classification, including metal products, general machinery manufacturing, machinery manufacturing, transportation equipment manufacturing, electronic and communication equipment manufacturing industry, electrical machinery and equipment manufacturing, instrumentation and office machinery manufacturing seven deducted 186 small consumer related manufacturing industry after class. Equivalent to the European countries referred to as "capital goods manufacturing", that is, we often say "the production of means of production industry."".

- Q:What are the principles, performances and uses of the commonly used construction machinery equipment?

- 2.: Principle: loader loader work, powered by a flywheel of the diesel engine to the hydraulic torque converter, the torque converter will drive to the gearbox, and before and after the output flange of the gearbox, the power output of the gearbox after the transmission shaft are respectively transmitted to the front and back drive axle to drive the wheels forward. Performance: 1) Central articulated frame, turning radius is small, flexible and convenient operation in narrow space; 2) using hydraulic mechanical transmission, according to the size of the external resistance and automatic stepless speed change, which can make full use of engine power, and improve the maneuverability, simplifies the loader operation. Is to protect the transmission parts and engine; 3) adopts full hydraulic steering, power shift transmission, hydraulic or flexible manipulation, portable and flexible machine; 4) stable and reliable operation; wide use of low-pressure off-road tires, rear axle swing, with good cross-country performance and through the performance by 5); gas cap oil disc brake system and brake foot up, emergency braking system, the braking performance is safe and reliable; 6) with advanced structure and bright cab. The air conditioning system operates more comfortably. Uses: loaders are mainly used for shovel, loading, unloading, transport of soil and stone a kind of bulk materials, rock and hard soil can also be slightly shovel operations.

- Q:Building materials, equipment, components and fittings products must have "three certificates" is what cards?

- Product quality certification, also known as product certification, internationally known as qualified certification. According to the 1991 implementation of the "people's Republic of China Quality Certification Management Regulations", the product quality certification is based on the product standard and relevant technical requirements, the certification institution confirmed by the certification and certification marks to prove that a particular product is in conformity with the relevant standards and technical requirements of the corresponding activities.

- Q:What kind of electrical equipment do you have? What are the main components of each device?

- Electrical equipment mainly refers to the transformer, reactor, capacitor, combination electric appliance, circuit breaker, transformer, lightning arrester, coupling capacitor, transmission line, power cable, grounding device, generator, condenser, motor, closed busbar, thyristor.

- Q:Where does Heilongjiang do the most construction machinery?

- All of the industry designated product range is roughly the same as that of China engineering machinery and other countries are also increased the railway engineering machinery, forklifts and industrial handling vehicles, decoration machinery, elevator, pneumatic tools and other industries.

- Q:Changsha Sanlian Building Machinery Fittings Factory

- The company in Changsha Hongdun business online can not find, provided by his address: two Changsha section of Xingsha Economic Development Zone Yuan Ming Road, I checked 114 specially call 12580 to booking the hotel near the road, not the road. Definitely a liar.

- Q:The building electrical iron pipe and the pipe line fixing member connected to what is called, what is called the iron pipe and the 86 fixed part of tin

- The distribution of the construction site, construction machinery and electric hand-held electric tools, lighting, construction site construction site: risk factors and lightning protection, the construction site of common electrical tools and instruments, the construction site of the electricity management, common electrical fault, accidents and accident cases.

- Q:What functions should be achieved in mechanical structure design?

- The design of mechanical structure is based on the overall design, according to the principle of the program to determine and draw a specific structure, in order to reflect the required functions. Is the working principle of the abstract concrete into some parts, the specific content in determining the structure of the material, shape, size, tolerance, heat treatment and surface conditions at the same time, we must consider the process, strength, stiffness, accuracy, and other parts of the relationship between each other and other issues. So, the direct product structure design is the technical drawings, but the design work is not a simple mechanical drawing, drawing only express design language, specific integrated technology is the basic content of structural design.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Forming Machine for Prestressed Hollow Core Panels

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords