Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

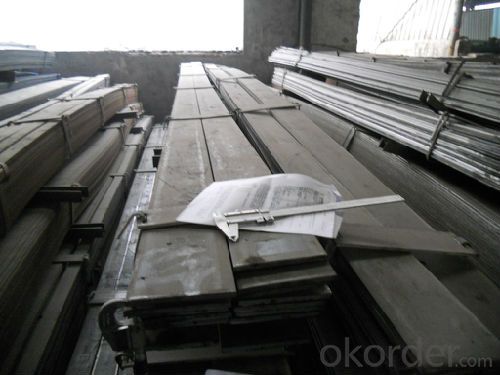

OKorder is offering Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Flat Steel

1.Thickness:1.5mm-14mm

2.Width:10mm-1010mm

3.Grade:Q235, Q345, A36

3.Factory producing, guaranteed material

| Flat Steel | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

| 20 | 2.0 | 6/9/12 | 0.31 |

| 20 | 2.5 | 6/9/12 | 0.39 |

| 20 | 2.75 | 6/9/12 | 0.43 |

| 25 | 2.5 | 6/9/12 | 0.49 |

| 25 | 3.75 | 6/9/12 | 0.74 |

| 30 | 2.5 | 6/9/12 | 0.59 |

| 30 | 3.5 | 6/9/12 | 0.82 |

| 30 | 9.75 | 6/9/12 | 2.30 |

| 40 | 3.5 | 6/9/12 | 1.10 |

| 40 | 4.75 | 6/9/12 | 1.50 |

| 40 | 11.75 | 6/9/12 | 3.69 |

| 50 | 2.75 | 6/9/12 | 1.08 |

| 50 | 4.5 | 6/9/12 | 1.77 |

| 50 | 9.75 | 6/9/12 | 3.83 |

| 60 | 5.5 | 6/9/12 | 2.60 |

| 60 | 7.5 | 6/9/12 | 3.53 |

| 60 | 11.5 | 6/9/12 | 5.42 |

| 80 | 5.5 | 6/9/12 | 3.45 |

| 80 | 7.5 | 6/9/12 | 4.71 |

| 80 | 11.75 | 6/9/12 | 7.38 |

| 100 | 3.25 | 6/9/12 | 2.55 |

| 100 | 4.75 | 6/9/12 | 3.73 |

| 100 | 7.5 | 6/9/12 | 5.89 |

| 120 | 9.75 | 6/9/12 | 9.18 |

| 120 | 11.75 | 6/9/12 | 11.07 |

| 150 | 9.75 | 6/9/12 | 11.48 |

| 150 | 11.5 | 6/9/12 | 13.54 |

| 150 | 13.5 | 6/9/12 | 15.90 |

| 160 | 11.75 | 6/9/12 | 14.76 |

| 200 | 9.5 | 6/9/12 | 14.92 |

| 250 | 5.75 | 6/9/12 | 11.28 |

| 340 | 7.75 | 6/9/12 | 20.68 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:What are the different certifications and standards for steel flat bars?

- There are several certifications and standards that apply to steel flat bars, ensuring their quality and suitability for various applications. Some of the most common certifications and standards include: 1. ASTM International (formerly known as the American Society for Testing and Materials): ASTM A108 is a standard specification for steel bars, carbon and alloy, cold-finished, while ASTM A36 is a standard specification for carbon structural steel that covers carbon steel shapes, plates, and bars of structural quality. 2. American Iron and Steel Institute (AISI): AISI 1018 is a common low carbon steel grade that is often used in steel flat bars. This grade conforms to AISI standards and is known for its excellent weldability and machinability. 3. Society of Automotive Engineers (SAE): SAE 4140 is a high-strength steel alloy commonly used in steel flat bars. It meets the SAE J404 standard, which specifies chemical composition limits for carbon and alloy steel bars. 4. European Norms (EN): EN 10025-2 is a standard specification for hot-rolled products of structural steels, including steel flat bars, that specifies technical delivery conditions for non-alloy structural steels. 5. International Organization for Standardization (ISO): ISO 683-3 is a standard that specifies the technical delivery requirements for steel bars, hot-rolled or forged, in various grades and conditions. 6. British Standards (BS): BS EN 10025-2 is a British standard that aligns with the European Norms and specifies the technical delivery conditions for non-alloy structural steels, including steel flat bars. It is important to note that specific applications may require additional certifications or standards. For example, steel flat bars used in construction may need to meet specific building codes or regulations set by local authorities. Additionally, industries such as aerospace or automotive may have their own unique certifications or standards to ensure the performance and safety of steel flat bars used in their applications.

- Q:What are the different methods of surface buffing for steel flat bars?

- There are several methods of surface buffing for steel flat bars, each with its own advantages and applications. Some of the most common methods include: 1. Hand buffing: This method involves using a handheld buffing wheel or pad to manually polish the surface of the steel flat bar. It is a cost-effective option for small-scale projects and provides a good level of control over the buffing process. 2. Machine buffing: Machine buffing utilizes powered buffing machines equipped with rotating wheels or pads to buff the steel flat bars. This method offers faster and more consistent results compared to hand buffing, making it suitable for large-scale projects or industrial applications. 3. Abrasive belt buffing: This method involves using abrasive belts, usually made of sandpaper or cloth, to remove imperfections and achieve a smooth surface on the steel flat bar. It is a versatile technique that can be used for both light and heavy buffing, depending on the grit size of the belt. 4. Chemical buffing: Chemical buffing involves the use of specialized chemicals or compounds to remove oxidation, stains, or other surface contaminants from the steel flat bar. This method is often used in conjunction with mechanical buffing to achieve a high-quality finish. 5. Electropolishing: Electropolishing is an electrochemical process that removes a thin layer of material from the steel flat bar's surface, resulting in a smooth, mirror-like finish. It is commonly used in industries where hygiene and corrosion resistance are critical, such as pharmaceutical or food processing. Each of these methods has its own advantages and limitations, and the choice of the most suitable method depends on factors such as the desired finish, project scale, available equipment, and budget. It is essential to consider these factors and consult with professionals or experts in the field to determine the best method for surface buffing steel flat bars.

- Q:Can steel flat bars be used for manufacturing conveyor systems?

- Yes, steel flat bars can be used for manufacturing conveyor systems. Steel flat bars are commonly used in conveyor system construction due to their strength, durability, and ability to support heavy loads. They provide a stable foundation and can be easily fabricated and assembled into various conveyor components.

- Q:How do steel flat bars compare to granite flat bars?

- Steel flat bars and granite flat bars have distinct differences in terms of material composition, properties, and applications. Steel flat bars, made from alloyed iron and carbon, offer high strength, durability, and versatility. They are commonly used in construction projects, industrial applications, and manufacturing due to their excellent load-bearing capacity and resistance to corrosion. Steel flat bars can be easily welded, machined, and shaped, making them suitable for a wide range of structural and decorative purposes. On the other hand, granite flat bars are composed of natural stone, formed from the cooling and solidification of magma. Granite flat bars are known for their aesthetic appeal, durability, and natural beauty. They are predominantly used in architectural and interior design applications, such as countertops, flooring, and decorative elements. Granite flat bars offer a unique and timeless look, with variations in color, pattern, and texture, making them a popular choice for enhancing the visual appeal of residential and commercial spaces. In summary, while steel flat bars are favored for their strength and versatility in structural applications, granite flat bars are valued for their aesthetic appeal and durability in architectural and design projects. The choice between the two depends on the specific requirements and desired outcome of the project at hand.

- Q:How do you determine the yield strength of a steel flat bar?

- The yield strength of a steel flat bar is typically determined through a tensile test. This involves subjecting the bar to an increasing tensile load until it reaches a point where it starts to deform plastically. The stress at which this occurs is the yield strength.

- Q:Can steel flat bars be used for creating supports or brackets?

- Indeed, supports or brackets can be fashioned using steel flat bars. Due to their robustness and longevity, steel flat bars are frequently employed to bear substantial weights or ensure structural steadiness. Custom brackets or supports for an array of purposes, including shelves, furniture, machinery, or construction undertakings, can be effortlessly crafted or welded using them. The availability of steel flat bars in various sizes and thicknesses further enhances their adaptability in design and application.

- Q:Why is it better to use round steel than that of flat steel in lightning protection?

- From the cross section, thermal stability as long as meet the discharge current can be, but from the lightning protection downlead selection, selection of round steel in order to prevent the tip discharge, so we generally do not choose flat edges as grounding, buried in the earth round and not flat how much difference, but in the same section of the case, of course, the contact area of flat steel and soil are large, relatively scattered large flow area, the construction is more convenient, in terms of price, we are willing to use flat, as for the problem of anti-corrosion, anti-corrosion paint, zinc can be taken, you know the thickness of galvanized steel pipe is generally not flat, so it really depends on the term for the use of galvanized flat steel is not bad.

- Q:Can steel flat bars be used in automotive applications?

- Yes, steel flat bars can be used in automotive applications. Steel flat bars are known for their strength, durability, and versatility, making them suitable for various automotive components and structures. They can be used in the construction of chassis frames, body panels, suspension components, and even in the fabrication of custom parts. The high tensile strength of steel flat bars allows them to withstand the significant forces and loads experienced by automotive parts during operation. Additionally, steel flat bars can be easily shaped, welded, and formed to meet the specific design requirements of automotive applications. Overall, the use of steel flat bars in automotive applications is common and widely accepted due to their excellent mechanical properties and cost-effectiveness.

- Q:How do you prevent steel flat bars from warping during welding or fabrication?

- To prevent steel flat bars from warping during welding or fabrication, there are several techniques and precautions that can be taken: 1. Proper storage and handling: Ensure that the steel flat bars are stored in a dry and stable environment to prevent any moisture absorption or exposure to extreme temperature fluctuations. Avoid bending or dropping the bars, as this can cause stress and deformation. 2. Preheating: Preheating the steel flat bars before welding can help reduce the risk of warping. This is especially important when working with thicker bars or when welding multiple bars together. Preheating helps to reduce thermal gradients and minimizes the stress caused by rapid cooling during welding. 3. Tack welding: Instead of welding the entire length of the bar at once, tack welding involves making a series of small welds along the joint. This helps to distribute the heat evenly and prevents excessive heat buildup in one area, which can lead to warping. 4. Welding sequence: Plan the welding sequence carefully, starting from the center and moving outward. This helps to evenly distribute the heat and reduces the risk of warping. Avoid welding too quickly or applying excessive heat, as it can cause distortion. 5. Proper fixturing: Using proper fixtures and clamps can help hold the steel flat bars in place during welding, minimizing movement and potential warping. Ensure that the bars are securely and uniformly clamped to prevent any bending or distortion during the welding process. 6. Backstep welding: This technique involves welding in short sections and moving backward along the joint. By applying heat in a controlled manner and allowing each section to cool before moving on, the risk of warping can be reduced. 7. Post-welding stress relief: After welding, it is important to relieve any residual stress in the steel flat bars. This can be done through various methods such as heat treatment or mechanical methods like hammering or rolling. Stress relief helps to minimize the risk of warping and improves the overall stability of the bars. By applying these precautions and techniques, it is possible to minimize the risk of warping during the welding or fabrication of steel flat bars, ensuring a more precise and reliable end product.

- Q:Are steel flat bars available in custom shapes?

- Yes, steel flat bars can be readily fabricated into custom shapes according to specific requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords