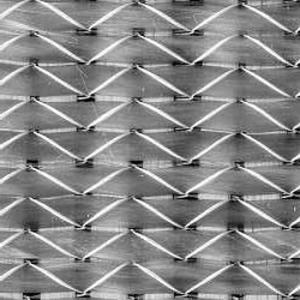

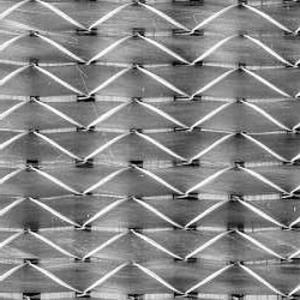

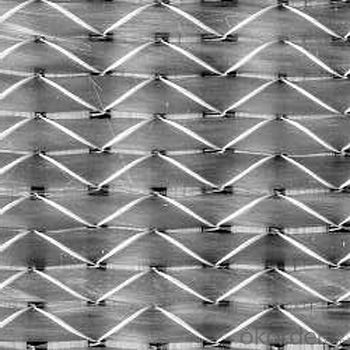

Fiberglass Multiaxial Fabric-UD (0° or 90°)880/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. It is commonly used as a core material in acoustic panels due to its excellent sound absorption properties. The fibers in the tissue help to dissipate sound energy and reduce echo and reverberation in a room.

- Q:How does the roll length of fiberglass mat tissue affect its handling?

- The roll length of fiberglass mat tissue can have an impact on its handling. A longer roll length can make it more cumbersome and difficult to handle, especially if it is heavy. It may require more physical effort to transport and maneuver, which can slow down the installation process. On the other hand, a shorter roll length may be more manageable and easier to handle, allowing for quicker and more efficient use during installation. Ultimately, the roll length should be chosen based on the specific requirements of the project and the capabilities of the individuals handling it.

- Q:Can fiberglass mat tissue be used for wall insulation?

- No, fiberglass mat tissue is not typically used for wall insulation. It is more commonly used in applications such as reinforcing and adding strength to composite materials like fiberglass panels or laminates. For wall insulation, other materials like fiberglass batts, mineral wool, or foam boards are typically used.

- Q:How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue directly affects its performance. Higher density mat tissue is typically stronger and more durable, providing better structural support and resistance to impact. On the other hand, lower density mat tissue is lighter and more flexible, making it suitable for applications where weight and flexibility are important factors. Ultimately, the density of fiberglass mat tissue plays a crucial role in determining its strength, flexibility, and overall performance.

- Q:Does fiberglass mat tissue require any special precautions during transportation?

- Special precautions must be taken during the transportation of fiberglass mat tissue as it is a delicate material that can easily be damaged if not handled correctly. To ensure safe transportation, several measures should be implemented. To begin with, it is necessary to pack the fiberglass mat tissue in a strong and durable material that can protect it from external impacts and vibrations. Heavy-duty cardboard boxes or wooden crates should be used to provide sufficient cushioning and support. Furthermore, it is vital to clearly label the packaging as "Fragile" or "Handle with Care" to alert handlers about the delicate nature of the product. This will help prevent any mishandling or rough treatment during transportation. In addition, the fiberglass mat tissue should be stored and transported in an upright position to minimize the risk of bending or folding that could potentially damage the material. It is also important to avoid placing heavy objects on top of the fiberglass mat tissue to prevent unnecessary pressure or crushing. Lastly, it is advisable to utilize secure and reliable transportation services with experience in handling delicate materials like fiberglass mat tissue. This ensures that the product is transported with the utmost care and attention, reducing the likelihood of damage during transit. By adhering to these special precautions, the risk of damage to the fiberglass mat tissue during transportation can be significantly reduced, guaranteeing its arrival in perfect condition.

- Q:Is fiberglass mat tissue resistant to fading?

- Fiberglass mat tissue is generally not resistant to fading. Fading occurs when a material loses its original color or brightness due to exposure to sunlight or other environmental factors. While fiberglass itself is known for its durability and resistance to weathering, the mat tissue used in fiberglass products is often susceptible to fading over time. This can be attributed to the binder or resin used to hold the fiberglass fibers together, as well as the pigments or dyes used to color the tissue. Exposure to UV rays and other outdoor elements can cause these components to break down and fade, resulting in a loss of color intensity or brightness. Therefore, if maintaining the aesthetic appearance of a fiberglass product is important, additional protective measures such as applying a UV-resistant coating or using pigments specifically designed for outdoor use may be necessary.

- Q:Can fiberglass mat tissue be used for insulating metal buildings?

- Fiberglass mat tissue is indeed capable of insulating metal buildings. This lightweight and flexible material offers efficient thermal insulation for metal structures. It is frequently applied as a layer between the metal panels and the interior of the building, effectively hindering heat transfer and enhancing energy efficiency. Moreover, fiberglass mat tissue resists moisture and discourages the growth of mold or mildew, making it an excellent option for insulating metal buildings. Nevertheless, it is crucial to ensure correct installation in order to optimize its insulation capabilities and avoid any gaps or air leakage.

- Q:Can fiberglass mat tissue be used for mold-making?

- Typically, fiberglass mat tissue is not used for mold-making. This lightweight material is made up of randomly oriented glass fibers that are bonded together with a binder. It is commonly utilized in the insulation, construction, and automotive industries for reinforcement purposes. When it comes to mold-making, other materials like silicone, latex, or polyurethane are more commonly employed. These materials possess the necessary properties to create molds that are flexible and capable of reproducing intricate details accurately. Moreover, they are user-friendly and can be poured or brushed onto the original object to form a mold. Conversely, fiberglass mat tissue lacks the flexibility and accuracy required for mold-making. It is not designed to easily conform to complex shapes or capture fine details. Additionally, it may not provide the desired level of flexibility needed to safely remove the original object from the mold without causing damage. Therefore, it is advisable to utilize specific mold-making materials that are specifically designed for this purpose instead of attempting to employ fiberglass mat tissue.

- Q:What is the expected lifespan of fiberglass mat tissue in chemical storage applications?

- The expected lifespan of fiberglass mat tissue in chemical storage applications can vary depending on factors such as the specific chemicals being stored, the conditions of storage (temperature, humidity, etc.), and the quality of the fiberglass material. However, fiberglass mat tissue is generally known for its durability and resistance to corrosion, making it suitable for long-term use in chemical storage applications. With proper maintenance and care, it can typically last for many years.

- Q:Is fiberglass mat tissue resistant to mildew and rot?

- Indeed, the resistance of fiberglass mat tissue to mildew and rot is undeniable. Crafted from delicate glass fibers interlaced to form a robust and enduring substance, fiberglass stands as a paragon. Its non-porous nature prevents moisture absorption, thus endowing fiberglass mat tissue with exceptional resistance against mildew proliferation and rot-induced decomposition. Moreover, fiberglass often receives protective coatings or additives that amplify its fortitude against these biological detriments. For this reason, fiberglass mat tissue emerges as an exemplary selection in settings where humidity or moisture pose a threat, such as bathrooms, outdoor structures, or regions prone to elevated humidity levels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Multiaxial Fabric-UD (0° or 90°)880/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords