Fiberglass Insect Screen Mesh/ Window Screen/Insect Mesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Insect Screen Mesh/ Window Screen/Insect Mesh

Introduction of Fiberglass Insect Screen Mesh:

Fiberglass Insect Screen Mesh is woven from PVC coated single fiber.

Fiberglass Insect Screen Mesh makes ideal material in industrial and agricultural buildings to keep away fly, mosquito and small insects or for the purpose of ventilation. The fiberglass insect mesh offers excellent properties of fire resistance, corrosion resistance, heat resistance, easy cleaning, good ventilation, high strength, stable structure, etc.

Features :

* Excellent Ventilation

* Sunshade

* Ultraviolet Radiation Proof

* Corrosion Resistance

* Resistance to Burn

* Easily cleaning

* Stable Shape

* Straight in Handle

* Long Service Life

Application:

1) Preventing the flies, mosquito etc from going into the house.

2) Filtering the fuzz and other sundries.

3) Decorating the windows and houses.

4) Protecting the children from falling.

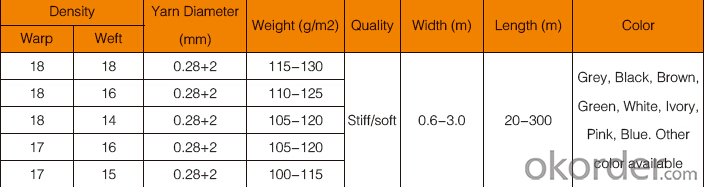

Specifications:

Products:

Pls feel free to contact me if any questions or inquiry,thank you!

- Q:Glue? What kind of glueWelded? How can weave mesh size of 0.12mm welding!!

- Of course, the welding, or want to other convenient glue certainly not. Hope can be adopted

- Q:Weaving method for mesh hammock?

- Take one of each of the two groups and hit a knot.

- Q:Wire mesh, barbed wire slope, diamond galvanized wire mesh, barbed wire money one square meter?

- Also used to protect and support the seawall, slope, Luqiao, reservoirs and other civil engineering. Is the flood control and flood of good material. Can also be used for the manufacture of Arts and crafts. Warehouse, tool room refrigeration, protective reinforcement, marine fishing fence and construction site fence, river, slope fixed soil (rock), residential safety protection, etc.

- Q:Method of weaving nets

- Two sets of yarns by twisting methods and machine twist twist, at the handover point with each other through the network into a network, called twist twist knotless net. Because the net yarn nodules without bending, the net is smooth, friction is reduced, but the twist twist machine of low efficiency, complicated preparation procedure, t-meshes Co., is only suitable for large woven mesh.

- Q:The difference between stainless steel gauze and 304 stainless steel gauze

- Different material316 nickel content of more than 304 nickel, and nickel is an important component of rust resistance of stainless steel

- Q:How to weave basketball net

- . Finally, from the Department of a vertical pull back to a place, with second straight (that is, ethylene propylene) parallel. So you have a square framework. Of course, the spider frame, not necessarily a full square, but it is always done in this way. This superb skill is the spider webs because it takes itself as the measuring instrument, determines the mechanical movement and position behind two on foot and textile process, so can be made into such a clearly demarcated screen. After a spider web, sometimes squatting in the network center; sometimes hidden in the shadows, and by a "signal" line, straight from the network center to the side, ready to accept online from the "signal" accurately, clever hunting food.

- Q:How to make a ring with a red rope?

- 3, take another one of the 40 cm red rope, folded in the middle, into the circle with a finger pinch, now divided into two lines;

- Q:HDMI line is woven nets play a role? Hope answer

- Ordinary woven wire is made of chemical fiber line, that is, to protect the inside of the wire bending and prevent external hard wire scratch. Followed by beauty.

- Q:Copper braid model TZ/TZX-15, what does it mean?

- TZX copper braided wire,

- Q:How to use the red rope weaving in the school fence

- First planning and then use the pattern of cross stitch embroidery on the line

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Insect Screen Mesh/ Window Screen/Insect Mesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords