Fiberglass Geogrid with CE Certificate and Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with CE Certificate and Best Price

Description Of Fiberglass Geogrid with CE Certificate and Best Price:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Main Features of Fiberglass Geogrid with CE Certificate and Best Price:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid with CE Certificate and Best Price:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with CE Certificate and Best Price:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

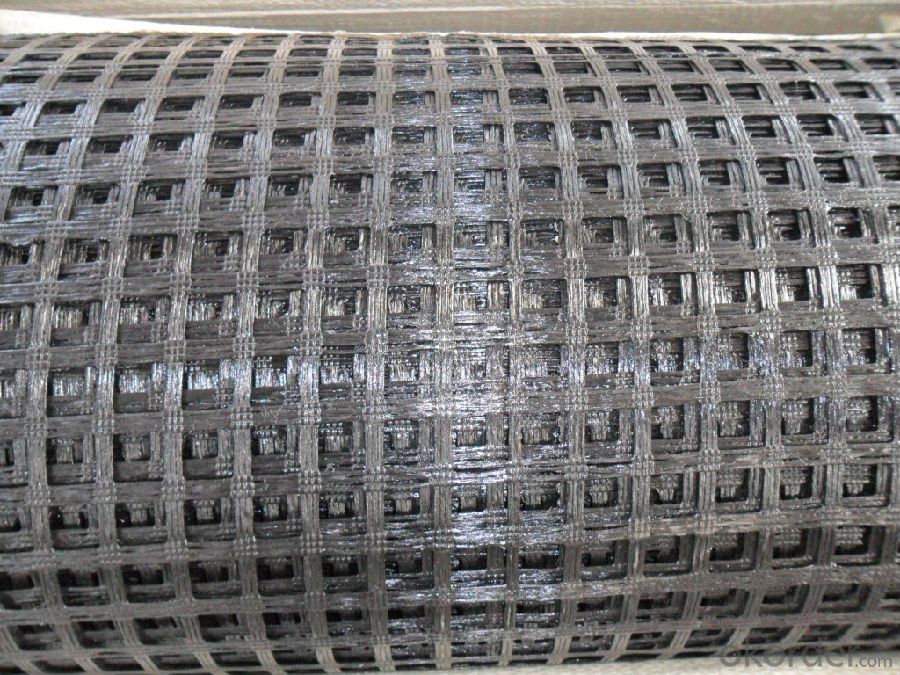

IMages of Fiberglass Geogrid with CE Certificate and Best Price:

FAQ of Fiberglass Geogrid with CE Certificate and Best Price:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Are geogrids resistant to hydrocarbons?

- Yes, geogrids are generally resistant to hydrocarbons.

- Q:Are geogrids suitable for use in soft soils?

- Yes, geogrids are suitable for use in soft soils. Geogrids are designed to provide reinforcement and stabilization to weak soils, including soft soils. They help to distribute loads and improve the overall strength of the soil, making them an effective solution for construction projects in areas with soft soil conditions.

- Q:Are geogrids resistant to chemical exposure?

- Yes, geogrids are generally resistant to chemical exposure. They are designed to withstand various environmental conditions, including exposure to chemicals, without significant degradation or loss of performance. However, the specific level of chemical resistance may vary depending on the type and composition of the geogrid material.

- Q:Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids are typically made of high-strength materials such as polyester or polypropylene, which provide excellent tensile strength and stability. They are designed to reinforce soil, prevent erosion, and improve the overall stability of slopes. Geogrids can effectively distribute loads and reduce soil movement, making them a reliable choice for slope reinforcement during excavation projects.

- Q:What is the typical installation time for geogrids?

- The typical installation time for geogrids can vary depending on various factors such as the size and complexity of the project, the type of geogrid being used, and the experience and efficiency of the installation crew. However, in general, geogrid installation can typically take anywhere from a few hours to a few days.

- Q:Are geogrids resistant to chemical leaching?

- Yes, geogrids are generally resistant to chemical leaching. Geogrids are typically made from high-density polyethylene (HDPE) or other chemically inert materials, which makes them highly resistant to chemical leaching. This resistance helps maintain the structural integrity and long-term performance of geogrids in various applications, including soil stabilization, erosion control, and reinforcement projects.

- Q:Can geogrids be used in ground stabilization for wastewater treatment plants?

- Yes, geogrids can be used in ground stabilization for wastewater treatment plants. Geogrids are often used in such applications to reinforce and stabilize the soil, preventing erosion and ensuring long-term stability of the facility's infrastructure. They provide additional support to the ground, reducing the risk of settling and maintaining the integrity of the wastewater treatment plant's structures.

- Q:PVC HF what is the material PVCHF bidirectional geogrid is like?

- General synthetic resin. Depending on the addition of plasticizers, can be divided into two types of hard and soft pvc.

- Q:What is the market price of the geotechnical grid in 2017

- (2) 0.3m thick medium (coarse) sand, artificial with mechanical leveling, 25T vibratory roller static pressure two times.

- Q:Can geogrids be used in reinforcement of underground parking structures?

- Yes, geogrids can be used in the reinforcement of underground parking structures. Geogrids are commonly used to provide stability and support to soil and rock structures. In underground parking structures, they can be used to reinforce the soil and prevent movement or collapse, ensuring the safety and longevity of the structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with CE Certificate and Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords