factory price!!! Galvanized/PVC Coated Welded Wire Mesh Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Factory price!!! galvanized/pvc coated Welded Wire Mesh Panel

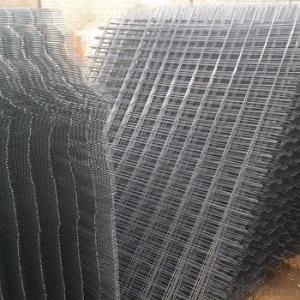

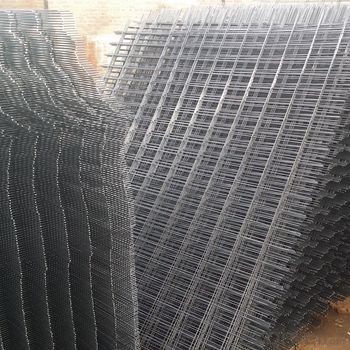

1. Welded Wire Mesh Description:

Welded wire mesh is made from stainless steel wire or galvanized wire,which shows good corrosion-resistance and oxidation-resistance,widely used for poultry houses,egg baskets,runway enclosures,draining racks,porch guards,rat-proofing, safety guards on machines, animal and plant pens and shelves, etc.

2.Main Features of the Welded Wire Mesh:

smooth mesh surface ,well-proportioned meshes ,strong welded points and bright luster .The mesh doesn’t come loose even if cut in parts or being exerted force on parts .Compared with general iron wire ,the products are better in respects of anti-corrosive and anti-rust.

3.Welded Wire Mesh Images

4.Welded Wire Mesh Specification

Specification List of Galvanized Welded Wire Mesh: | ||

Opening | Wire Diameter | |

In inch | In metric unit(mm) | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 |

5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 |

1" x 1/2" | 25.4mm x 12.7mm | 16,17,18,19,20,21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 |

1" x 2" | 25.4mm x 50.8mm | 14,15,16 |

2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 |

Technical Note: 1.Standard roll length: 30m;width: 0.5m to 1.8m 2.Special sizes available at request | ||

Special sizes are also available.

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Australia.

(2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What are the different types of steel wires and their applications in telecommunications?

- There are several types of steel wires commonly used in telecommunications. These include galvanized steel wires, stainless steel wires, and high-tensile steel wires. Galvanized steel wires are coated with a layer of zinc, which provides corrosion resistance and durability. They are commonly used for overhead transmission lines, telephone cables, and fiber optic cables. Stainless steel wires are highly resistant to corrosion and have excellent strength properties. They are often used in marine environments, underground installations, and for aerial cables where high tensile strength is required. High-tensile steel wires are known for their exceptional strength and toughness. They are used in applications where heavy loads and long spans are involved, such as suspension cables for bridges and power transmission lines. Overall, these different types of steel wires play a crucial role in the telecommunications industry by providing strength, durability, and reliability for transmitting signals and supporting communication infrastructure.

- Q:How does steel pipe coating for oil pipelines work?

- Steel pipe coating for oil pipelines works by applying a protective layer onto the surface of the pipe to prevent corrosion and extend its lifespan. The coating typically involves a combination of corrosion-resistant materials, such as epoxy or polyethylene, which are applied through various methods like hot-dip galvanizing or fusion bonded epoxy coating. This coating acts as a barrier against moisture, chemicals, and environmental factors, ensuring the pipeline's integrity and preventing leakage or degradation over time.

- Q:How is steel used in the production of fire-resistant materials?

- Steel is often used as a reinforcing material in the production of fire-resistant materials. It is used to strengthen and support structures, such as fire doors, fireproof walls, and fire-resistant coatings. Steel's high melting point and durability make it an ideal choice to enhance the fire resistance of these materials, providing added protection against heat and flames.

- Q:How are steel beams used in building structures?

- Steel beams are used in building structures as load-bearing elements that provide strength and stability. They are commonly used in the construction industry due to their high strength-to-weight ratio, allowing for the creation of large, open spaces without the need for excessive columns or supports. Steel beams distribute weight evenly, helping to support the weight of floors, walls, and roofs, and can withstand significant forces, such as wind and earthquakes. They are essential in constructing high-rise buildings, bridges, and industrial structures, where durability and structural integrity are paramount.

- Q:How is steel plate cut and shaped?

- Steel plate is typically cut and shaped using various methods such as plasma cutting, laser cutting, and water jet cutting. These techniques involve using high-energy sources to melt, burn, or erode the metal, allowing for precise and intricate shapes to be formed. Additionally, steel plate can be shaped through processes like bending, rolling, and stamping, which apply force to deform the material into desired forms.

- Q:How do steel products contribute to the agricultural and farming sector?

- Steel products contribute to the agricultural and farming sector in multiple ways. They are used in the construction of farm buildings, barns, and sheds, providing sturdy and durable structures to house livestock, store crops, and protect machinery and equipment. Steel fencing and gates are also commonly used to secure and divide farming land, ensuring the safety and containment of animals and crops. Additionally, steel is utilized in the manufacturing of agricultural machinery and equipment, such as tractors, plows, harvesters, and irrigation systems, due to its strength and versatility. These steel-made tools and implements enhance productivity, efficiency, and precision in various farming operations, leading to increased yields and overall agricultural performance.

- Q:What are the advantages of using steel in bridge construction?

- There are several advantages of using steel in bridge construction. Firstly, steel is a highly durable and strong material, ensuring the longevity and structural integrity of the bridge. Secondly, steel has a high strength-to-weight ratio, making it a lightweight option that can support heavy loads. Additionally, steel is flexible and can withstand extreme weather conditions, such as high winds or earthquakes, making it suitable for various environments. Moreover, steel bridges can be prefabricated off-site, reducing construction time and costs. Lastly, steel is a sustainable material as it can be recycled, minimizing its environmental impact.

- Q:What are the different types of steel chains and their uses in the automotive manufacturing process?

- There are several types of steel chains used in the automotive manufacturing process. Some common types include roller chains, timing chains, and conveyor chains. Roller chains are commonly used in engines and power transmission systems to transfer power from the engine to various components. Timing chains are used to synchronize the movement of engine valves and pistons, ensuring proper engine performance. Conveyor chains are utilized in assembly lines and production processes to move and transport automotive parts. These steel chains play a crucial role in the automotive manufacturing process by ensuring smooth operation, power transmission, and efficient production.

- Q:How do steel products contribute to the transportation industry?

- Steel products contribute to the transportation industry in various ways. Firstly, steel is used in the manufacturing of vehicles, such as cars, trucks, trains, and ships, providing them with structural strength and durability. Steel's high strength-to-weight ratio makes it ideal for constructing lightweight yet resilient bodies, frames, and components, enhancing overall safety and performance. Additionally, steel is employed in the production of infrastructure elements like bridges, tunnels, and railway tracks, ensuring their sturdiness and longevity. Overall, steel products play a crucial role in enhancing the reliability, efficiency, and safety of transportation systems worldwide.

- Q:What are the applications of steel mesh?

- Steel mesh is widely used in various applications such as construction, reinforcement, fencing, landscaping, and industrial sectors. It is commonly used for concrete reinforcement, providing strength and stability to structures like buildings, bridges, and highways. Steel mesh is also utilized in fencing systems, ensuring security and safety in residential, commercial, and agricultural settings. Additionally, it is employed in landscaping projects to support plants and prevent soil erosion. In industrial settings, steel mesh is used for filtration, sieving, and separation processes. Overall, the applications of steel mesh are diverse, making it a versatile and essential material in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

factory price!!! Galvanized/PVC Coated Welded Wire Mesh Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords