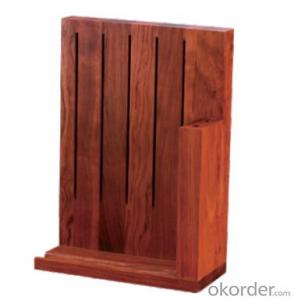

F-KB094 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:Carbonized bamboo

N.W.:4.636kg

MEAS:38.5*27*12cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization.

And after high temperature and high pressure, so that form a hard carbide particles layer on the surface.At the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.

At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q:Oblique bed CNC lathe in the row on the turret mounted electric turret, and then install the power head, you can also install the tailstock, I do not know this? Cheap not?

- If it is a CNC lathe that can install electric turret and four power head, but before installing X to find out the shaft of the motor power and torque (because you are inclined bed, before installation will calculate), and your head is driven by motor or pneumatic, according to the modified circuit and PLC the ladder diagram (if the pneumatic power head, aerodynamic outfit). Install the tailstock it depends on your machine is installed the tailstock, general CNC lathe should have the appropriate location to install the tailstock, you look to see if there is any guide, the tailstock in your machine is generally a mountain, or two. As for the price that depends on your choice of the tower and power head specifications, the brand to be there is the cost of renovation. It depends on the specific situation. You say these three kinds of knife tower and power head, good change is not very expensive, but artificial expensive

- Q:What is the difference between NC machine tool and tool holder

- In front of the turret with rear turret X axis is not the same, the general system programming does not have what difference, the front turret program got rear turret lathe bed on the same processing, but also have different, like Beijing DTM window system, front and rear arc knife tool that is just the opposite.

- Q:What is the difference between the NC lathe and the tool post

- Also, the most important thing is to look at the direction of the knife, there are positive and reverse difference, that is, M3 and M4

- Q:Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- In order to install the taper shank drill, you need to buy or process a tooling, the taper of the inner hole 1:16, the size of the outer circle is determined by the hole of the boring tool holder on your lathe.

- Q:What are the parts of the lathe and tool holder

- A lathe is a machine with many parts assembled.A part of a lathe.

- Q:The difference between the turret and the rear turret NC lathe

- The classification processing example scope advantages and disadvantages of different composition of 2.3 ordinary lathe and CNC lathe CNC lathe uses a directory of the two introduction 2.1 CNC lathe 2.2 CNC lathe 2.4 CNC lathe 2.5 CNC lathe CNC lathe CNC lathe 2.6 three 3.1 NC turning process and tooling 3.2 CNC lathe programming 3.3 part four references

- Q:GSK980TA CNC lathe tool holder how to move

- Hand hold tool motor, and then press the knife, I feel that there is no motor movements. 1, if the turret motor does not act, it should be a circuit problem, please check whether or not the work of the holder of the relay, the power supply is not normal, etc.. 2, if there has been support motor action and feeling in the action, that should be a tool of mechanical failure, please rest on the lower left one screw off with six angle wrench tool to see whether the worm shaft can rotate the turret rotation if it will rest to 45 degrees and then try to change the knife, if not to move it please remove the knife. 3, if the knife motor action and click No action, it may be broken or the knife knife signal line transmitting disk bad.Numerical control lathe: in the numerical control machine tool processing part, mainly depends on the processing procedure, it is different with the ordinary machine tool, does not need to make, the replacement many molds, the jig, does not need to adjust the machine frequently. Therefore, the NC machine is suitable for the processing of parts of frequent replacement of the occasion, which is suitable for single and small batch product development and production, and new products, so as to shorten the preparation cycle, save a lot of equipment costs.

- Q:What is the reason why the turret of NC lathe is not maintained?

- May rest inside the lines are wrong, may also have a lid on the knife frame out

- Q:CNC lathe turret and turret turret that good

- The rest of different structures, different forms of cutter positioning, tool installation precision, repeated installation accuracy, with the knife and machine are different, if you have this requirement, in the choice of when it is necessary to consider the.

- Q:The first reason is that the cutter shaft of the motor shaft is broken for a shaft / how long it will not be able to die!

- Open the cleaning to keep the knife holder into the garbage or not to check whether the motor is enough

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

F-KB094 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products