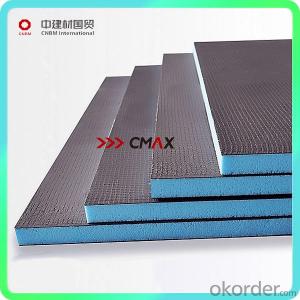

Extruded Polystyrene Boards - Superior Thermal Insulating material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | XPS600/1200 | Superior Thermal Insulating material: | Energy-saving XPS board | Safety recycled prefabricated XPS board: | CE approved XPS heat insulation foam board |

Packaging & Delivery

| Packaging Detail: | Plastic Bag,10pcs/package,wrapping with plastic film |

| Delivery Detail: | 5-10 working days |

Specifications

Extruded Polystyrene Boards - Superior Thermal Insulating material

CE approved

Thickness:20mm-50mm

Length: 1200mm-6000mm

Extruded Polystyrene Boards - Superior Thermal Insulating material

Heat Insulation, Water-proof, Noise-elimination, Anti-corrosion, Anti-aging, Light-weight, High Compressive Strength and Low Moisture permeability.

Like many construction materials, Extruded polystyrene boards made up of a 100% closed honey-comb cells structure is combustible. It should not be exposed to flame or other ignition sources. Extruded polystyrene boards should be covered with a thermal barrier or otherwise installed in accordance with applicable building codes.

Model | XPS600 | XPS1200 | ||

Width | 600mm | 1200mm | ||

Length | 1200mm 1800mm 2400mm | |||

Type | embossing,rough surface,fire retardant. | |||

Thickness | 20mm 30mm 40mm 45mm 50mm 75mm 100mm | |||

Color | grey | |||

Pcs/Pack | 25 pcs 16 pcs 12 pcs 11 pcs 10 pcs 6 pcs 5 pcs | |||

Common Specification | 20*600*2400mm 25*600*2400mm 30*600*2400mm 40*600*2400mm 45*600*2400mm 50*600*2400mm 75*600*2400mm 80*600*2400mm 100*600*2400mm | |||

Plastic Bag for Packing | 40'HQ | 40'GP | 20'GP | |

50mm-600mm-1200mm | 10pcs/package0.035m3/pc 0.35m3/package | |||

180packages | 138packages | 55packages | ||

65m3 | 50m3 | 20m3 | ||

1800pcs | 1380pcs | 550pcs | ||

In bulk | In bulk | In bulk | ||

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q:What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q:How to distinguish between good and bad insulation board insulation board

- Class flexible management refers to the class teacher in the student's psychological and behavioral laws on the basis of the use of non-mandatory way, in the minds of students to produce a potential persuasive, the use of the class teacher's own positive factors to influence and guide students

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Caigang rock wool sandwich panel Scope Caigang rock wool sandwich panels for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling , Cut off and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding the right amount of binder, curing processing and made. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on. Color rock wool sandwich panels Product Features 1. Rock wool is inorganic insulation materials, iron ore slag as the main raw material, by melting, with high-pressure steam jet cooling, with a light, thermal conductivity is small, good elasticity , Non-combustible, non-rotting, non-rotting, chemical stability, and excellent sound insulation.2 The rock wool sandwich panels are widely used in addition to the general structure of heat insulation and insulation To the use of a variety of fire insulation places. Caigang rock wool sandwich board specifications thickness Caigang rock wool sandwich board sub-system board and manual board two, Caigang sandwich panel is made of two layers of color coated steel Layer, through the automatic compound molding machine, in the steel plate coated with adhesive glue, while embedded in the board on both sides of the thin-walled steel, the pressure, blanking made of sheet metal. . the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × . L × 1150 × . L × 1150 × . handmade rock wool color steel sandwich panel specifications: L × 985 × . Sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. . rock wool density: ≥ 120kg / m. thermal conductivity: ≤ 0.046w / m.k. combustion performance: A-level (non-combustible)

- Q:Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- the inner wall insulation, as the name suggests is the wall inside the house Hu Dangan citrus spinning song dead building, the use of spraying, bonding, pouring, etc

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- Is a normal phenomenon, frost in the frost when the frost, and a temperature probe.

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q:Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruded Polystyrene Boards - Superior Thermal Insulating material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords