Embossed Stainless Steel Sheet metal with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

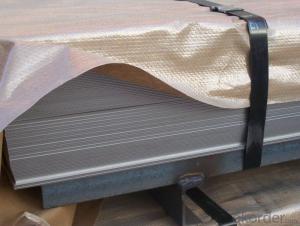

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:What are the different types of stainless steel sheet surface coatings available?

- There are several types of stainless steel sheet surface coatings available, including brushed or satin finishes, mirror finishes, bead blasted finishes, and embossed or textured finishes.

- Q:Do stainless steel sheets have a warranty?

- Stainless steel sheets usually have a warranty, which can differ in duration and terms depending on the manufacturer and specific product. It is advisable to consult with the supplier or manufacturer to obtain precise information regarding the warranty coverage. Generally, defects in material or workmanship are covered by the warranty, and if any problems occur within the specified warranty period, the stainless steel sheet can be replaced or repaired. To maintain the warranty's validity, it is crucial to adhere to the care and maintenance instructions provided by the manufacturer.

- Q:Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers. Stainless steel is a durable and corrosion-resistant material, making it suitable for exterior applications. It provides an attractive and modern finish that can enhance the aesthetic appeal of a building. Stainless steel sheets can be easily fabricated and installed to fit around columns, creating a sleek and seamless appearance. Additionally, stainless steel is low maintenance and easy to clean, making it a practical choice for column covers that are exposed to the elements.

- Q:How do you polish stainless steel sheets?

- Achieving a polished look for stainless steel sheets can be accomplished by following a few straightforward steps. Begin by ensuring that the surface is immaculate and devoid of any dirt or debris. To eliminate any stains or marks, a mild detergent or stainless steel cleaner can be used. Next, utilize a soft cloth or sponge to apply either a stainless steel polish or a mixture of vinegar and olive oil. Apply the polish in the direction of the grain, which typically appears as a linear pattern on the stainless steel surface. Once the polish has been applied, utilize another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to exhibit a shining, polished appearance. If necessary, repeat the process in areas that require further polishing, ensuring that all excess polish is wiped away to prevent streaks or residue. It is crucial to consider that different stainless steel finishes may necessitate specific polishing techniques or products. For optimal results, always consult the manufacturer's instructions or guidelines.

- Q:How do you prevent scratching on stainless steel sheets during handling and installation?

- To avoid scratching stainless steel sheets while handling and installing them, there are several precautions you can take: 1. Apply protective covering: Prior to handling or installation, it is advisable to apply a protective film or covering on the surface of the stainless steel sheets. This covering acts as a barrier, safeguarding against scratches and scuff marks during transportation and installation. It is important to ensure that the chosen covering is suitable for stainless steel and leaves no residue when removed. 2. Handle with caution: It is crucial to be mindful of how you handle the stainless steel sheets. Avoid dragging or sliding them against rough surfaces or each other, as this can result in scratches. Instead, use appropriate lifting techniques and handle the sheets with clean, dry hands or gloves to minimize the risk of leaving marks. 3. Utilize suitable tools: When working with stainless steel sheets, ensure that you use tools specifically designed for this purpose. Refrain from using tools with rough or abrasive surfaces that could potentially scratch the stainless steel. Opt for tools made from soft materials or those with protective coatings to reduce the chances of surface damage. 4. Keep work areas clean: Before installing stainless steel sheets, it is essential to ensure that the work area is clean and free from any debris or particles that could potentially scratch the surface. Use a clean cloth or soft brush to wipe down the area, removing any dirt, dust, or loose materials that could cause scratches during the installation process. 5. Secure sheets during transportation: If you need to transport stainless steel sheets, it is crucial to secure them properly to prevent any movement or shifting that could lead to scratches. Utilize appropriate packaging materials such as foam inserts, edge protectors, or straps to keep the sheets in place and minimize the risk of damage. By adhering to these preventive measures, you can significantly reduce the likelihood of scratching stainless steel sheets during handling and installation, ensuring a flawless finish and preserving the quality of the material.

- Q:What are the different surface finishes available for stainless steel sheets?

- There are several different surface finishes available for stainless steel sheets, each offering unique characteristics and aesthetics. 1. No.1 Finish: This is the most common and widely used finish for stainless steel sheets. It has a rough, dull appearance with visible grain lines. No.1 finish is obtained by hot rolling the stainless steel and is suitable for applications where a rough finish is acceptable. 2. No.2B Finish: This finish is obtained by cold rolling the stainless steel and then annealing it, resulting in a smooth, reflective surface with a slightly dull appearance. It is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. No.2D Finish: Similar to No.2B finish, No.2D finish is achieved by cold rolling and annealing the stainless steel. However, it has a smoother and shinier appearance, making it suitable for applications requiring a more polished look. 4. No.3 Finish: Also known as a brushed finish, No.3 finish is achieved by polishing the stainless steel with abrasive belts or brushes. It has a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. No.4 Finish: This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than No.3 finish. It has a more refined and smoother appearance, often used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. No.8 Finish: Also known as a mirror finish, No.8 finish is achieved by polishing the stainless steel with progressively finer abrasive materials until a highly reflective surface is obtained. It provides a glossy, mirror-like appearance, ideal for architectural and decorative applications. 7. Hairline Finish: Hairline finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are some of the most common surface finishes available for stainless steel sheets. The choice of finish depends on the desired aesthetics, functionality, and application requirements.

- Q:What are the different types of perforated patterns available for stainless steel sheets?

- Stainless steel sheets come in a variety of perforated patterns, each serving specific purposes and meeting different aesthetic preferences. Let's explore some commonly used patterns: 1. The round hole pattern is the most widely used and basic design. It consists of evenly spaced round holes that allow for excellent airflow and drainage. It finds its applications in industrial filtration systems or as decorative panels. 2. The square hole pattern, similar to the round hole pattern, offers a more geometric and uniform appearance. It is often preferred for architectural and decorative purposes, providing a modern and sleek look. 3. The slotted hole pattern consists of elongated and rectangular holes, allowing for more flexibility in terms of airflow and visibility. It is commonly used in grills or air ventilation systems where better drainage or a higher open area is required. 4. The hexagonal hole pattern offers a unique and visually appealing design. It provides excellent strength and structural integrity, making it suitable for applications requiring durability, such as safety barriers or machine guards. 5. In addition to the standard patterns, there are various decorative hole patterns available for stainless steel sheets. These patterns feature intricate designs or shapes, adding an artistic touch to architectural and interior design applications. When selecting a perforated pattern for stainless steel sheets, it is important to consider the specific requirements of your project, such as airflow, visibility, drainage, or aesthetic appeal. Consulting with a supplier or expert in the field can help you make an informed decision based on your needs.

- Q:Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q:What's the difference between stainless steel 302 and 304?

- Plate type heat exchanger, corrugated pipe, household appliances (1, 2 kinds of tableware, kitchen cabinet, indoor pipeline, water heater, boiler, bath), auto parts (windshield wiper, muffler, mold), medical appliances, building materials, chemical, food industry, agriculture, marine parts, millet mobile phone etc.. 304 stainless steel is a nationally recognized food grade stainless steel.

- Q:How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Stainless Steel Sheet metal with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords