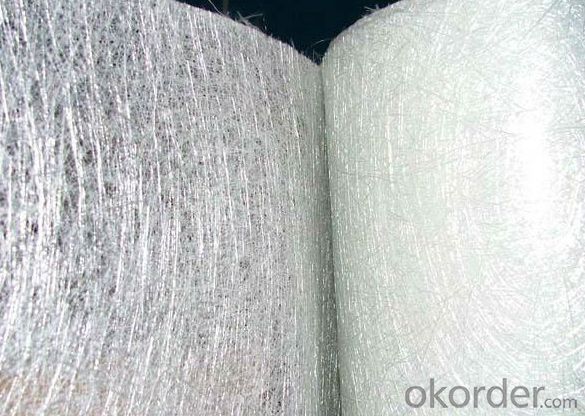

E-glass Chopped Strand Mat 2900mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Breif Introduction

Chopped strand mat with width 2900mm

2.Main Features

With Excellent compatibility with resin,heating resistance,Faster and well wet-out

Chopped strand mats are made of chopped strands of 50mm in length,which are randomly dispersed and bonded together by the polyester binder in powder or emulsion.

Chopped strand mats are mainly used in FRP fields,such as hand lay-up,filament winding and molding process. The typical products are panels,tanks,boats,automotive parts,cooling towers,pipes and so on.

3.Specification

AreaWeight :300GSM

Roll Weiht: 145KG

Roll Width: 2900mm

Binder: Emulsion

4.FAQ

Q: Which knid of payment terms can you accept?

A: We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q:Is fiberglass mat tissue suitable for insulation in chemical processing plants?

- Yes, fiberglass mat tissue is suitable for insulation in chemical processing plants. It is highly resistant to corrosion and chemicals, making it an ideal choice for such environments. Additionally, fiberglass mat tissue offers excellent thermal insulation properties, helping to maintain optimal temperature levels in the plant.

- Q:What is the density of fiberglass mat tissue?

- The density of fiberglass mat tissue may differ depending on its specific type and manufacturer. On average, it has a density of approximately 1.5 g/cm³ or 1500 kg/m³. It should be emphasized that the density might slightly vary depending on the thickness and composition of the fiberglass mat tissue.

- Q:Does fiberglass mat tissue require any special precautions during transportation?

- Yes, fiberglass mat tissue does require special precautions during transportation. It should be handled with care to avoid any damage or breakage as it can easily tear or become compromised. It is advisable to use proper packaging and secure the material to prevent movement or shifting during transportation. Additionally, protective measures such as wearing gloves, masks, and safety glasses should be taken to avoid any potential irritation or respiratory discomfort caused by the fiberglass fibers.

- Q:Can fiberglass mat tissue be used in wet environments?

- Yes, fiberglass mat tissue can be used in wet environments. Fiberglass mat tissue is designed to be resistant to moisture and can withstand exposure to water, making it suitable for applications in wet environments. It is commonly used in industries such as construction, marine, and automotive, where components or structures are exposed to water, humidity, or moisture. The material's resistance to water ensures that it maintains its structural integrity and does not degrade or lose its performance properties when subjected to wet conditions.

- Q:How does fiberglass mat tissue compare to cellulose insulation?

- Fiberglass mat tissue and cellulose insulation differ in terms of material composition and insulation properties. Fiberglass mat tissue is made from fine glass fibers, while cellulose insulation is composed of recycled paper fibers treated with fire-retardant chemicals. Fiberglass mat tissue offers higher R-value, meaning it provides better thermal insulation and energy efficiency. Additionally, it is resistant to moisture and does not promote mold growth. On the other hand, cellulose insulation is more affordable, environmentally friendly, and provides better sound insulation. Ultimately, the choice between the two depends on specific insulation needs, budget, and environmental considerations.

- Q:How does fiberglass mat tissue compare to mineral wool insulation?

- Fiberglass mat tissue and mineral wool insulation are two common types of insulation materials used in construction and other industries. While both materials serve the purpose of providing thermal insulation, there are some differences between the two. Fiberglass mat tissue is made from fine glass fibers that are bonded together to form a mat. It is lightweight and flexible, making it easy to handle and install. Fiberglass mat tissue is also resistant to moisture, mold, and pests, making it a durable option for insulation. It has a high R-value, which measures the material's ability to resist heat flow, making it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals such as basalt, diabase, or slag. It is typically denser and heavier than fiberglass mat tissue. Mineral wool insulation is known for its excellent fire resistance properties, as it is non-combustible and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, mineral wool insulation can absorb moisture, which can reduce its effectiveness over time. In terms of thermal performance, both materials offer similar levels of insulation. However, fiberglass mat tissue tends to be slightly more efficient due to its higher R-value. Additionally, fiberglass mat tissue is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between the two will depend on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is important to consider these factors and consult with professionals to determine the most suitable insulation material for a particular application.

- Q:Can fiberglass mat tissue be used for architectural facades?

- Yes, fiberglass mat tissue can be used for architectural facades. It is a versatile material that offers excellent strength, durability, and weather resistance, making it suitable for various applications including architectural facades.

- Q:Can fiberglass mat tissue be used for making lightweight furniture?

- Fiberglass mat tissue has the capability to create lightweight furniture. This material is composed of glass fibers bonded with resin, resulting in a thin and light substance. Its exceptional strength-to-weight ratio has made it widely used in different industries such as automotive, aerospace, and construction. In furniture production, fiberglass mat tissue can be layered and shaped into various forms, providing both structural support and rigidity while keeping the weight of the furniture low. This makes it an excellent choice for crafting lightweight furniture pieces that are easy to move and transport. Furthermore, fiberglass mat tissue exhibits impressive durability and resistance to moisture, chemicals, and heat, making it suitable for indoor and outdoor furniture applications. Its versatility empowers furniture designers and manufacturers to create innovative and distinctive designs while maintaining the desired lightweight characteristics. However, it is crucial to consider that the quality and performance of the final product also rely on the overall design, construction, and other materials used in conjunction with fiberglass mat tissue. To ensure the furniture's longevity, stability, and safety, proper engineering and manufacturing techniques should be applied.

- Q:What is the expected lifespan of fiberglass mat tissue in power generation applications?

- The expected lifespan of fiberglass mat tissue in power generation applications can vary depending on various factors such as the specific application, environmental conditions, maintenance practices, and quality of the material used. However, fiberglass mat tissue is typically designed to have a long lifespan and can often last for several decades in power generation applications when properly installed and maintained.

- Q:How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue can have a significant impact on its conformability. Generally, a wider width of fiberglass mat tissue allows for greater flexibility and adaptability to different surfaces and shapes. This is because a wider mat tissue can cover larger areas, allowing for smoother transitions and better conformability to irregular surfaces. On the other hand, a narrower width of fiberglass mat tissue may be more rigid and less able to conform to complex shapes or contours. It might struggle to properly adhere to uneven surfaces, resulting in potential gaps or imperfections. Additionally, a narrower width may limit the flexibility and maneuverability of the mat tissue during installation or application. Therefore, the width of fiberglass mat tissue is an important factor to consider when determining its conformability. A wider width generally offers better conformability and the ability to cover larger areas, while a narrower width may have limitations in adapting to complex surfaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Chopped Strand Mat 2900mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000MT m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords