Durable in use and corrosion-resistant GRE pipe

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

- Option:

- Pipe diameter:DN40-DN600 Operating temperature: 65℃ or 93 ℃ Design pressure: 1.0-5.0mpa

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Advantages:

1. Durable in use and corrosion-resistant:the surface of internal and external can resist many kinds corrosion of chemicals, crude oil. injected water and bacteria.

2. Light weight: 24% weight of ductile iron, it is convenient for installation in the absence of heavy machinery and large tools.

3. Low cost: Internal surface can reduce friction and the cost of transporting by pump.

4. Efficient and eneray saving: GRE pipe compared with steel tube can reduce the consumption of heat.

5. The solution of pipe system: The whole FRP pipe have different size, pipe joints, pressure rating for choice.

6. The long life cycle and low cost: There is almost no maintenance costs after installation and use, and it has higher lifetime cost compared with steel tube.

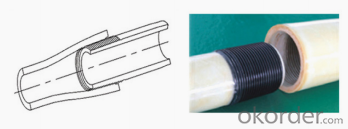

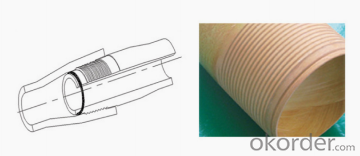

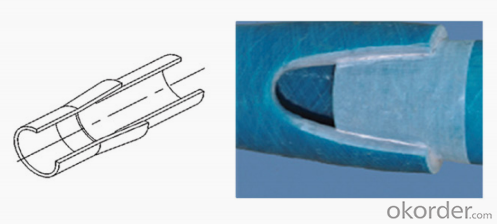

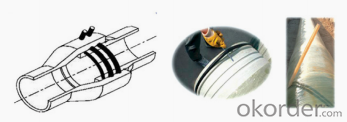

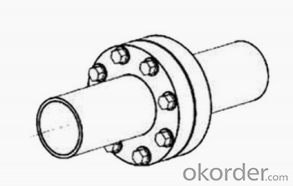

Joint type:

1. API thread application: High pressure oil & gas & water pipeline

2.T thread joint application: High pressure oil & gas & water pipeline

3.Bonding joint application: Underground low pressure pipeline

4.Locking key joint application: Underground low pressure pipeline

5.Flange joint application: Pipe and pipe or pipe joint other equipment

6.Lamination joint application: Low pressure pipeline connection

Produts Application:

1.Oil & gas-onshore:

Crude oil gathering line

Injected water

Macromolecule

Process pipeline in station

LNG pipeline

1. Vessel and offshore platform

Ballast water

Cooling water

DrainageFresh water pipe

Drinking water

Fire fighting water pipe

Sea water transport

Sewage transport

2. Bittern special purpose

Transport bittern

Transport sewage

3. Underground pipe and casing pipe

CBM casing pipe

Shale gas casing pipe

Underground oil pipe

Oil casing pipe

Product Performance:

The corrosion picture comparison between ordinary steel pipe and FRP pipe:

Performance comparison between ordinary steel pipe and FRP pipe:

Comparison Item | GRE pipe | Ordinary Steel Pipe |

Corrosion Resistance | Good corrosion resistance | Bad corrosion resistance |

Service Life | 20-30 years(the designed service life is more than 50 years ) | 5-10 years (nocathodic protection and preservative) |

Frictional Resistance | Smooth inner wall can reduce the accumulation of paraffin and scale;Low surface friction increase the flow of fluid velocity | The rough inner surface is easy to form scale and paraffin deposition;High surface friction leads to loss of workpressure |

Insulation Performance | There is no minimum and additional insulation material" requirement under high temperature and harsh environment | A lot of heat loss under the condition of high temperature |

Engineering Installation | Light weight, low cost of installation and transport | High weight, high cost of installation and transport |

Maintenance Fecs | It almost need no repair | Need anti-corrosive paint, cathodic protection and corrosion monitoring |

Environmental Performance | Low energy consumption in the process of productionand use | High energy consumption in the process of production and use |

Production Information:

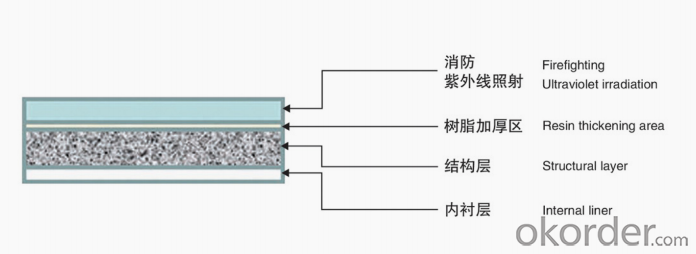

GRE wall structure:

∙ Pipe internal liner is used for anti-corrosion

∙ Pipe structural layer is used for pipe strength

∙ Anti-uv protection can used in pipe external to resist uv & the weathering exposure and environmental protection

∙ If high flow conducting electrostatic discharge need, GRE pipe can be used to conduct harmful static electricity discharged in the danger zone

In the fire, protective layer meet the fire resistance performance of protection box, required by firefighting, and produce less harmful gas.

Jet fire and fire-resistant experiment:

Level 3 fire-resistant experiment:

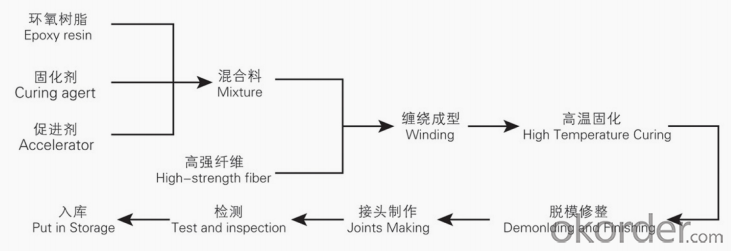

Production Method:

∙ Filament winding is used for both pipe and fitting production.

∙ The fiber glass will be winded on the mandrel after soaked into the resin. The mandrel will be rotated according to programmed mode.

∙ Multiply mandrels can be winded at the same time with one winding machine which has improved the work efficiency and guaranteed the quality.

∙ The winding of pipe fittings I flange, elbow, tee, coupling ) are made of two axis winding machines.

Production Process:

Quality Control:

Universal tester Differential scanning calorimeter (DSC)

Drying oven Fatigue tested machine

Before delivery, all pipes conduct 100% hydrostatic pressure monitoring in accordance with API standard.

Standard & Specification:

∙ API 15HR Specification for High Pressure Fiberglass Line Pipe

∙ API 15LR Specufcation for Low Pressure Fiberglass Line Pipe and fittings

∙ ISO 14692 Petroleum and natural gas industries - Glass-reinforced plastics (GRP) piping

∙ AWWA C950 Standard for fiberglass pressure pipe

∙ AWWA M45 Fiberglass pipe design

∙ IMO Res.A753(18) Plastic pipes on the ship

∙ ASTM F1173 Standard Specification for Thermosetting Resin Fiberglass Pipe Systems to Be Used for Marine Applications

∙ ASTM---D2996 Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

∙ API 5B Casing, tubing. line pipe thread specification

- Q:What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- FRP material has the characteristics of excellent corrosion resistance, no underground water or sewage pipe tube with acidic or alkaline causes no damage to the use of the product, and the product itself, do not need to do any protective measures, steel pipe and concrete pipe does not have the advantage.

- Q:Glass fiber reinforced plastic pipe to withstand 1.0MPa pressure, pipe wall to do how much thickness?

- Glass tube wall thickness is generally determined by the manufacturer design, with stereotypes products and sequences, you can choose according to the pressure level.

- Q:What is the thickness of all types of FRP pipes?

- The standard effective length of the tube is 6m and 12M, and the production methods include fixed length winding process, centrifugal casting process and continuous winding process of three kinds. Classification can be carried out according to the product process method, pressure grade PN and stiffness grade SN.

- Q:Why more and more people choose FRP pipe?

- The cost performance of FRP pipes is higher than that of PP, PVC, PE or concrete, and the strength, hardness and toughness of PP, PE and PVC are not as good as those of FRP pipes

- Q:What are the advantages of FRP pipes?

- The relative density is between 1.5~2.0 and only 1/4~1/5 of carbon steel, but the tensile strength is close to or even higher than that of carbon steel, while the specific strength can be compared with that of advanced alloy steel.

- Q:There is a gap between the new glass fiber reinforced plastic pipe and its through wall. How can the plug be prevented from leaking through the cracks around the pipe?

- Large glass fiber reinforced plastics plants such as the United States and Asia, with FRP through the cabin, can be used to solve your problem, the gap is filled with special blowing agent. In this way, the continuity of FRP material can be guaranteed.

- Q:What are the disadvantages of glass fiber reinforced sand pipe?

- In brief, the disadvantage of FRP sand pipe is that the pipe is restrained by external environment, such as construction environment and span of support. Used in drinking water engineering, loess and sandy soil in the north are more suitable, but in ponds, marshes, mountains, then the pipeline backfill will increase the project investment. Used for overhead glass steel pipe lines, supporting the size of the gap is also the success or failure of the pipeline.

- Q:The role of glass fiber reinforced plastic cooling towers

- Central air conditioning also has cooling tower function is to play the role of cooling circulation.

- Q:FRP pipe and 0.7 thick galvanized pipe which cost is low?

- Glass steel pipeline, FRP pipe and 0.7 galvanized steel pipe glass steel pipes cost is obviously low, FRP pipe material factory manufacturing costs and labor costs are relatively low, the price is only about the same thickness of galvanized pipe 60-70%, I hope you can help!

- Q:Glass tube has different diameters with different prices. Who can elaborate?

- If it is a sand lined pipe, the rigidity grade is 25005000750010000Prices are calculated according to these

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Durable in use and corrosion-resistant GRE pipe

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m

- Supply Capability:

- 5000 m/month

- Option:

- Pipe diameter:DN40-DN600 Operating temperature: 65℃ or 93 ℃ Design pressure: 1.0-5.0mpa

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.

Lianyungang Zhongfu Lianzhong Composites Group Co.,Ltd.