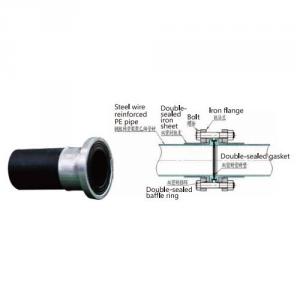

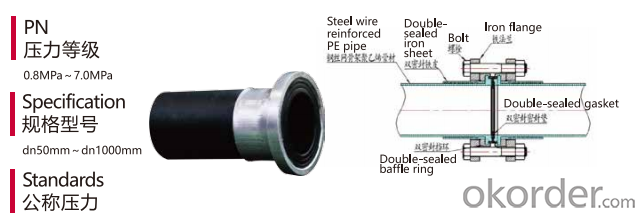

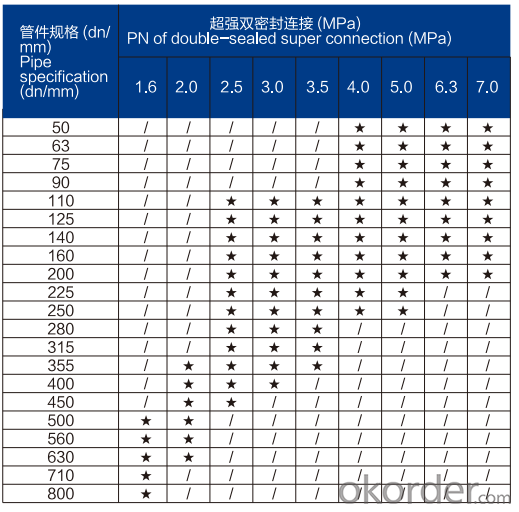

Double Sealed Super Connection for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Double Sealed Super Connection for Pipeline System

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Are plastic pipe fittings suitable for chemical injection systems?

- Yes, plastic pipe fittings can be suitable for chemical injection systems, depending on the specific chemicals being used. It is important to consider the compatibility of the chemicals with the type of plastic used in the fittings to ensure they can withstand the chemical's corrosive properties and maintain structural integrity.

- Q:How do you repair a broken plastic pipe fitting?

- To repair a broken plastic pipe fitting, you can start by turning off the water supply and draining any remaining water from the pipe. Then, remove the broken fitting by cutting it out using a hacksaw or pipe cutter. Once removed, clean the ends of the pipe and the new fitting thoroughly. Apply a generous amount of PVC primer to both the pipe and fitting, followed by PVC cement. Quickly join the two together, making sure they are aligned properly. Allow the cement to dry according to the manufacturer's instructions before turning on the water supply again.

- Q:Plastic pipe fittings and plastic doors and windows on the stain in what way?

- With the immersion of detergent in warm water, and then wipe with a sponge that wash water. Then wipe it with a dry towel.

- Q:How do you remove a plastic pipe fitting?

- To remove a plastic pipe fitting, you typically need to follow these steps: 1. Turn off the water supply: Locate the main water valve and shut it off to prevent any leaks or water flow while removing the fitting. 2. Drain the pipe: Open a faucet or valve downstream from the fitting to drain any water remaining in the pipe. 3. Cut the pipe: Using a pipe cutter or hacksaw, carefully cut the plastic pipe on both sides of the fitting. Be cautious not to damage the adjacent pipe or the fitting itself. 4. Loosen the fittings: Depending on the type of fitting, you may need to use a wrench or pliers to loosen and remove any nuts, clamps, or rings securing the fitting to the pipe. 5. Separate the fitting: Once the nuts/clamps are loose, gently twist and pull the fitting away from the pipe. If it's stubborn, applying heat with a heat gun can help soften the plastic and make it easier to remove. 6. Clean the pipe ends: After removing the fitting, use a utility knife or sandpaper to clean any burrs or debris from the pipe ends before installing a new fitting or reconnecting the existing one.

- Q:How do plastic pipe fittings handle changes in water pressure?

- Plastic pipe fittings are designed to withstand changes in water pressure quite effectively. The materials used, such as PVC or CPVC, have inherent flexibility that allows them to expand and contract with variations in pressure. Additionally, these fittings are typically designed with features like ribbed or threaded connections, which enhance their ability to handle different pressure levels. Overall, plastic pipe fittings are known for their durability and reliability in managing variations in water pressure.

- Q:Can plastic pipe fittings be used in industrial applications?

- Yes, plastic pipe fittings can be used in industrial applications. They are commonly used in various industries such as chemical processing, water treatment, and food processing, among others. Plastic pipe fittings offer several advantages such as corrosion resistance, lightweight construction, and ease of installation. However, the specific application requirements and conditions should be considered to determine the most suitable type of plastic and fitting material.

- Q:Are plastic pipe fittings resistant to high-temperature fluids?

- Yes, plastic pipe fittings are generally resistant to high-temperature fluids. However, the specific resistance may vary depending on the type of plastic used and the temperature range. It is important to select fittings made from materials that are suitable for the desired temperature conditions to ensure their durability and performance.

- Q:Can plastic pipe fittings be used in fish farming systems?

- Yes, plastic pipe fittings can be used in fish farming systems. Plastic fittings are commonly used in aquaculture due to their durability, chemical resistance, and affordability. They are suitable for various applications, such as water supply, drainage, aeration, and filtration systems in fish farming operations.

- Q:How do plastic pipe fittings handle seismic activity?

- Plastic pipe fittings generally have the ability to handle seismic activity well. The flexibility and elasticity of plastic materials help absorb and distribute the forces generated during an earthquake, reducing the risk of pipe damage or failure. Additionally, plastic fittings often have a higher tolerance for movement and can withstand ground settlement or shifting without cracking or leaking. However, it is important to ensure that the fittings are properly installed and meet the necessary building codes and seismic design requirements to ensure optimal performance.

- Q:Are plastic pipe fittings suitable for use in pharmaceutical manufacturing?

- No, plastic pipe fittings are not suitable for use in pharmaceutical manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Double Sealed Super Connection for Pipeline System

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords