DI Pipes in Water Infrastructure,Ductile Iron Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

DI Pipes in Water Infrastructure

Ductile iron pipe is a pipe made of ductile iron commonly used for potable water transmission and distribution.

Specifications:

1. ISO 2531 & EN 545 Standard

2. K8, K9, K10 C Class

3. Internal Linings: Portland Cement

4. External Coating: Bitumen/ Epoxy

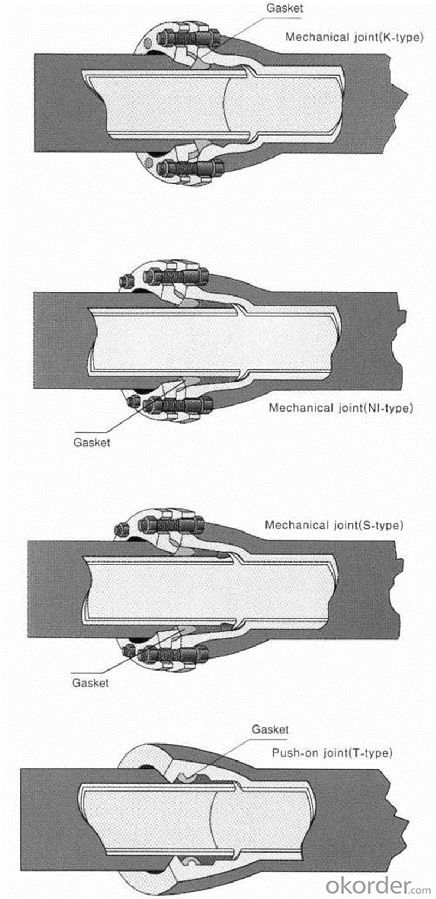

5. Joint Type: T Joint, K Joint, N1 Joint, MJ Joint and Flange Joint.

| DN(mm) | OD(mm) | Wall Thickness(mm) | Weight of Socket (kg) | Unit Weight for Barrel (kg/m) | Total Weight(kg) (Standard Length=6000mm) | ||||||

| K8 | K9 | K10 | K8 | K9 | K10 | K8 | K9 | K10 | |||

| 80 | 98 | 6 | 6 | 6 | 3.7 | 12.2 | 12.2 | 12.2 | 76.8 | 76.8 | 76.8 |

| 100 | 118 | 6 | 6.1 | 6.1 | 4.7 | 14.9 | 15.1 | 15.1 | 94.1 | 95.4 | 95.4 |

| 150 | 170 | 6 | 6.3 | 6.3 | 8.5 | 21.8 | 22.8 | 22.8 | 139.4 | 145.4 | 145.4 |

| 200 | 222 | 6 | 6.4 | 6.4 | 10.9 | 28.7 | 30.6 | 30.6 | 183.6 | 194.6 | 194.6 |

| 250 | 274 | 6 | 6.8 | 7.5 | 15 | 35.6 | 40.2 | 44.3 | 228.8 | 255.8 | 280.8 |

| 300 | 326 | 6.4 | 7.2 | 8 | 22.2 | 45.3 | 50.8 | 56.3 | 293.3 | 326.3 | 360.3 |

| 350 | 378 | 6.8 | 7.7 | 8.5 | 26.5 | 55.9 | 63.2 | 69.6 | 361.8 | 405.8 | 443.8 |

| 400 | 429 | 7.2 | 8.1 | 9 | 32.5 | 80 | 75.5 | 83.7 | 433 | 482 | 532 |

| 500 | 532 | 8 | 9 | 10 | 50.6 | 92.8 | 104.3 | 116 | 607.8 | 676.8 | 743.8 |

| 600 | 635 | 8.8 | 9.9 | 11 | 71.9 | 122 | 137.3 | 152 | 803.6 | 894.6 | 983.6 |

| 700 | 738 | 9.6 | 10.8 | 12 | 85.3 | 155 | 173.9 | 193 | 1015 | 1129.2 | 1243.2 |

| 800 | 842 | 10.4 | 11.7 | 13 | 108.7 | 192 | 215.2 | 239 | 1261 | 1400.1 | 1543.1 |

| 900 | 945 | 11.2 | 12.6 | 14 | 140.1 | 232 | 260.2 | 289 | 1532 | 1701.1 | 1874.1 |

| 1000 | 1048 | 12 | 13.5 | 15 | 174.3 | 275 | 309.3 | 343 | 1824 | 2030 | 2234 |

| 1200 | 1265 | 13.6 | 15.3 | 17 | 267.5 | 374 | 420.1 | 466 | 2512 | 2787.8 | 3063.8 |

- Q:How does ductile iron pipe handle changes in pipe diameter or size?

- Ductile iron pipe is designed to handle changes in pipe diameter or size with relative ease. It possesses excellent flexibility and can accommodate variations in pipe dimensions without compromising its structural integrity. This is mainly due to its unique composition, which includes a significant amount of graphite nodules that provide ductility and elasticity to the material. When faced with changes in pipe diameter or size, ductile iron pipe can be easily manufactured or modified to meet specific requirements. It can be cast or fabricated in various diameters and lengths, allowing for seamless integration and adaptability within a pipeline system. This versatility is particularly beneficial in scenarios where different pipe sizes need to be connected or when the pipeline layout requires alterations. Moreover, ductile iron pipe's superior mechanical properties make it capable of withstanding the stresses and forces associated with changes in pipe diameter or size. It exhibits high tensile strength, impact resistance, and durability, ensuring that it can handle the internal and external pressures exerted on the pipe during operations. Additionally, the jointing systems used with ductile iron pipe contribute to its ability to handle changes in diameter or size. Various joint types, such as push-on, restrained, or mechanical joints, provide secure and leak-free connections between different pipe sections. These joints allow for easy assembly and disassembly, enabling efficient adjustments to the pipe diameter or size as needed. In conclusion, ductile iron pipe is well-equipped to handle changes in pipe diameter or size due to its inherent flexibility, adaptability, and robustness. Its composition, manufacturing capabilities, and jointing systems all contribute to its ability to accommodate variations in pipe dimensions without compromising its performance.

- Q:Does the cast iron have size 250? What's the performance?

- You should be the casting grade or material, if it is ductile iron, said generally between QT400-15 or QT700-2 different indicators, said in front of the tensile strength, the elongation rate refers to the back, China is now the lowest grade of nodular cast iron material is QT400-15, such as QT250.In addition, the number 250 you refer to may also be a code name for ductile iron parts, such as 200, 300, etc., which are manufactured by the factory as required by the project.Gray iron, which has a 250 brand, is generally referred to as HT250, but it is not ductile iron.The machine on the ductile iron and gray iron are used, but generally not made of grey cast iron gear

- Q:What is the lifespan of ductile iron pipes?

- The lifespan of ductile iron pipes can vary depending on various factors such as the quality of the pipes, the installation conditions, and the environment in which they are used. However, on average, ductile iron pipes have a lifespan of around 50 to 100 years. This makes them a durable and long-lasting option for water and sewer infrastructure. With proper maintenance and regular inspections, ductile iron pipes can continue to function effectively and efficiently for several decades. It is important to note that factors like corrosion, soil conditions, and water chemistry can impact the lifespan of these pipes, so monitoring and addressing these issues can help extend their lifespan.

- Q:Are ductile iron pipes resistant to impact damage?

- Ductile iron pipes are known for their exceptional strength and durability, making them highly resistant to impact damage. Due to their unique composition, which includes a higher percentage of carbon and silicon, ductile iron pipes possess excellent toughness and flexibility. This allows them to withstand external forces and impacts, such as heavy construction equipment or accidental impacts during installation or maintenance activities. Additionally, ductile iron pipes have a high resistance to cracking and fracturing, further enhancing their ability to withstand impact damage. However, it is important to note that while ductile iron pipes are highly resistant to impact damage, they are not completely immune. Extreme or repeated impacts may still cause damage, albeit to a lesser extent than other types of pipes. Regular inspections and maintenance are crucial to identifying and addressing any potential impact damage to ensure the long-term integrity and performance of ductile iron pipes.

- Q:How are leaks repaired in ductile iron pipe?

- Leak repairs in ductile iron pipes are typically carried out using various methods depending on the severity and location of the leak. One commonly used technique is the application of epoxy-based sealants or leak repair clamps. For small leaks, epoxy sealants are commonly used. This involves applying a specialized epoxy compound to the leaking area, which then hardens and forms a durable seal over the leak. The epoxy is carefully applied to the surface of the pipe, covering the leakage point and any surrounding damaged areas. This method is effective for small leaks and can provide a long-lasting solution. In cases where the leak is larger or more severe, leak repair clamps are often employed. These clamps are designed to provide a mechanical seal over the leak, using rubber gaskets and bolts to secure the clamp tightly around the pipe. The pressure from the clamp compresses the gasket onto the pipe, creating a watertight seal and preventing further leakage. Leak repair clamps are available in various sizes to accommodate different pipe diameters. In both cases, it is crucial to properly prepare the pipe surface before applying the repair method. The area around the leak must be cleaned and dried thoroughly to ensure good adhesion of the epoxy or proper sealing with the clamp. Additionally, it is essential to follow the manufacturer's instructions and guidelines for the chosen repair method to ensure a successful and long-lasting repair. It is important to note that these repair methods are temporary solutions and may not be suitable for all situations. In some cases, particularly for extensive pipe damage or aging infrastructure, it may be necessary to replace the affected pipe section entirely. Professional assessment and guidance from qualified technicians or plumbers are recommended when dealing with leaks in ductile iron pipes to ensure proper repairs and minimize the risk of future issues.

- Q:What is the maximum allowable deflection for ductile iron pipes?

- The maximum allowable deflection for ductile iron pipes is typically specified by industry standards and guidelines, such as those provided by the American Water Works Association (AWWA) and the Ductile Iron Pipe Research Association (DIPRA). These standards specify the maximum allowable deflection as a percentage of the pipe's outside diameter. According to AWWA C150/A21.50 and DIPRA's Technical Bulletin No. 10, the maximum allowable deflection for ductile iron pipes can vary depending on factors such as pipe size, wall thickness, and soil conditions. However, a common rule of thumb is that the maximum allowable deflection should not exceed 3% of the pipe's outside diameter. It is important to note that exceeding the maximum allowable deflection can result in potential structural issues and reduced performance of the ductile iron pipe. Therefore, it is crucial to adhere to the industry standards and guidelines to ensure the proper installation and functioning of ductile iron pipes.

- Q:How do ductile iron pipes handle water hammer?

- Ductile iron pipes are well-suited to handle water hammer due to their inherent strength and flexibility. The high tensile strength of ductile iron helps absorb and dampen the pressure surges caused by water hammer, preventing any significant damage to the pipes. Additionally, the inherent ductility of these pipes allows them to flex and absorb the impact of water hammer, reducing the likelihood of cracks or bursts. Overall, ductile iron pipes provide a reliable and durable solution for managing water hammer in water distribution systems.

- Q:How does ductile iron pipe handle thermal expansion and contraction?

- Ductile iron pipe is able to handle thermal expansion and contraction effectively due to its inherent flexibility and strength. Its unique composition allows it to withstand the expansion and contraction caused by temperature fluctuations without breaking or becoming brittle. This property is crucial in preventing any damage to the pipe or its fittings, ensuring a reliable and durable pipeline system.

- Q:What is the typical lifespan of ductile iron pipe?

- The lifespan of ductile iron pipe can differ based on several factors, including the pipe's quality, the conditions it faces, and the maintenance practices employed. On average, ductile iron pipe typically lasts about 100 years. This longevity is a result of its inherent strength and durability, allowing it to withstand high pressure and various environmental conditions. Furthermore, ductile iron pipe is often coated with protective materials like cement mortar lining or polyethylene encasement, which further enhance its durability. Regular inspections and maintenance can also contribute to extending the lifespan of ductile iron pipe by promptly identifying and addressing any issues or potential damages.

- Q:How does ductile iron pipe perform in areas with high groundwater contamination?

- Ductile iron pipe is renowned for its durability and resistance to corrosion, rendering it an appropriate option for regions with significant groundwater pollution. By means of its protective lining and coating, the pipe effectively obstructs direct contact between the iron and groundwater, thereby minimizing the likelihood of corrosion and decay. Furthermore, ductile iron pipe possesses the capacity to withstand external pressures, making it less susceptible to harm resulting from shifting soils or groundwater flow. This characteristic proves particularly advantageous in areas with high groundwater contamination as it guarantees the pipe's structural integrity remains intact, preventing leaks or bursts. Moreover, ductile iron pipe boasts a lengthy service life, which in turn diminishes the necessity for frequent replacements and reduces the potential for groundwater pollution caused by pipe failures. On the whole, ductile iron pipe performs exceptionally well in regions plagued by high groundwater contamination, providing a dependable and robust solution for transporting water or wastewater while simultaneously safeguarding the surrounding environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DI Pipes in Water Infrastructure,Ductile Iron Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords