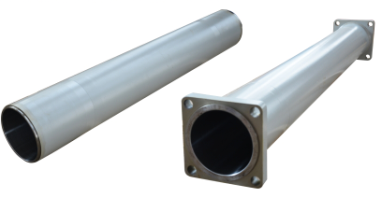

DELIVERY CYLINDER(SCHWING ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2125MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q:Are there any specific warranty options available for concrete pump spare parts?

- Yes, there are specific warranty options available for concrete pump spare parts. These warranties may vary depending on the manufacturer or supplier, but they typically cover defects in materials or workmanship for a specified period of time. It is advisable to check with the manufacturer or supplier to understand the specific warranty options and terms available for concrete pump spare parts.

- Q:Are there any regulatory requirements for the quality and standards of concrete pump spare parts?

- Concrete pump spare parts are subject to regulatory requirements that govern their quality and standards. These requirements are in place to guarantee safety, performance, and durability. These regulations are established by entities such as governmental agencies or industry associations, with the aim of safeguarding consumers and ensuring the proper functioning of concrete pumps. Several common regulatory requirements apply to concrete pump spare parts: 1. Certification: Authorized organizations may certify spare parts or subject them to specific testing processes to verify compliance with quality and performance standards. This certification helps ensure the safety and reliability of the spare parts. 2. Material Standards: Specific material standards may be imposed on spare parts. For example, the materials used in their construction must meet requirements for strength, corrosion resistance, or temperature resistance. 3. Design and Manufacturing Standards: The design and manufacturing processes of spare parts must adhere to certain standards. These standards cover dimensions, tolerances, manufacturing techniques, and quality control procedures in order to ensure consistent and reliable performance. 4. Performance and Compatibility Standards: Spare parts should be designed and manufactured to perform within defined parameters and be compatible with the concrete pump system they are intended for. This guarantees proper and safe functioning of the spare parts when installed in the pump. 5. Documentation and Labeling: Regulatory requirements often mandate that spare parts be accompanied by proper documentation, including user manuals, installation instructions, and maintenance guidelines. Additionally, labeling requirements may exist to clearly identify the spare parts and their specifications. Manufacturers, suppliers, and users of concrete pump spare parts must be aware of and comply with these regulatory requirements to ensure the safety and effectiveness of the concrete pump system.

- Q:Can I get spare parts for concrete pump hoppers and agitators?

- Yes, it is possible to get spare parts for concrete pump hoppers and agitators. Many manufacturers and suppliers of concrete pumps and equipment offer spare parts for their products. You can contact the manufacturer or supplier of your specific concrete pump hopper or agitator to inquire about the availability and pricing of spare parts. Additionally, there are also specialized companies that provide spare parts for various brands and models of concrete pumps and equipment. These companies typically have a wide range of spare parts in stock and can ship them to you as needed.

- Q:What is the concrete delivery pump?

- The utility model relates to a machine for continuously conveying concrete along a pipeline by utilizing pressure, which is mainly used for building, bridges and tunnels

- Q:What is the role of a concrete pump hopper agitator blade?

- The role of a concrete pump hopper agitator blade is to ensure the consistency and flow of the concrete while it is being pumped. The agitator blade is designed to mix the concrete in the hopper, preventing it from settling or becoming too thick. By continuously stirring the concrete, the agitator blade helps to maintain its proper consistency, making it easier to pump and ensuring a more uniform distribution of the material. This is particularly important when working with large volumes of concrete or when pumping over long distances, as it helps to prevent blockages and maintain a smooth and efficient pumping process. Overall, the agitator blade plays a crucial role in the successful operation of a concrete pump, ensuring that the concrete remains in a workable state throughout the pumping process.

- Q:How do concrete pump spare parts help in the pumping process?

- Concrete pump spare parts play a crucial role in the pumping process by ensuring the smooth and efficient operation of the concrete pump. These spare parts are designed to enhance the performance and longevity of the pump, ultimately leading to increased productivity and cost savings. One of the key advantages of using concrete pump spare parts is their ability to improve the overall pumping efficiency. These parts are manufactured with precision to maintain the optimal flow of concrete through the pump. For instance, the wear plate, wear ring, and S valve play a vital role in reducing friction and enhancing the pumping performance. By minimizing friction and maintaining a consistent flow, these spare parts prevent clogging and blockages, enabling the concrete to be pumped smoothly and efficiently. Furthermore, concrete pump spare parts are essential for minimizing downtime and maintenance costs. As the pump operates continuously, wear and tear are inevitable. However, regularly replacing worn-out parts with high-quality spare parts can significantly extend the lifespan of the pump and reduce the need for frequent repairs. By investing in durable and reliable spare parts, operators can avoid unexpected breakdowns and costly repairs, ensuring uninterrupted and efficient pumping operations. Moreover, concrete pump spare parts contribute to the safety of the pumping process. Components such as the safety valve, hopper grate, and control system play a critical role in preventing accidents and ensuring the well-being of the operators. These spare parts are designed to ensure the safe and controlled pumping of concrete, minimizing the risk of equipment failure and potential hazards. In conclusion, concrete pump spare parts are essential in the pumping process as they improve efficiency, reduce downtime and maintenance costs, and enhance safety. By investing in high-quality spare parts, operators can optimize the performance of the pump, increase productivity, and achieve cost savings in the long run.

- Q:Are there any specific troubleshooting steps for identifying issues with concrete pump spare parts?

- Concrete pump spare parts can be identified for issues by following specific troubleshooting steps. These steps include conducting a thorough visual inspection of the spare parts to look for signs of wear, damage, or misalignment. Cracks, breaks, or any visible signs of damage should be checked for. The functionality of the spare parts can be tested by operating the concrete pump and paying attention to abnormal noises, vibrations, or irregular movements. A pressure test can be performed by connecting a pressure gauge to the pump and checking if it reaches the desired pressure levels. Any abnormal pressure fluctuations can indicate issues. A flow test can be conducted to evaluate the flow rate of the concrete through the pump and check for any blockages or irregular flow patterns. The spare parts should be inspected for leaks or fluid seepage, which can indicate faulty seals, gaskets, or fittings. Technical manuals provided by the manufacturer can be consulted for troubleshooting guidelines specific to the concrete pump spare parts. If unable to identify the issue, it is advisable to seek expert advice from a qualified technician or the manufacturer's technical support team. By following these troubleshooting steps, it becomes easier to promptly identify and address any issues with concrete pump spare parts.

- Q:What do these types of concrete pumps mean?

- Concrete conveying pump HBT80-18-16: according to the national standard "GB/T13333-2004_ concrete pump"

- Q:What is the purpose of a concrete pump electric motor?

- The concrete pump electric motor serves the purpose of supplying the necessary power and energy to operate the concrete pump. By converting electrical energy into mechanical energy, the motor propels the hydraulic system of the pump. This hydraulic system is accountable for drawing in concrete from the hopper and propelling it through the pipes to the intended destination. Through its smooth and efficient operation, the electric motor guarantees precise placement of the concrete and enhances productivity at construction sites. Moreover, the utilization of an electric motor eradicates the requirement for manual labor and minimizes emissions in contrast to conventional diesel-powered pumps, thereby presenting a more environmentally conscious alternative.

- Q:What is the function of a concrete pump hopper grate handle?

- The function of a concrete pump hopper grate handle is to provide a means of manually controlling the opening and closing of the hopper grate on a concrete pump. The hopper grate is a crucial component of the pump that allows for the introduction of concrete into the pumping system. By operating the handle, the operator can adjust the position of the grate to regulate the flow of concrete and prevent any large debris or foreign objects from entering the pumping system. This helps to ensure the smooth operation of the pump and maintain the quality of the concrete being pumped. Additionally, the handle allows for easy and convenient access to the hopper grate for maintenance and cleaning purposes. Overall, the concrete pump hopper grate handle plays a vital role in controlling the flow of concrete and maintaining the efficiency and reliability of the pumping process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DELIVERY CYLINDER(SCHWING ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:2125MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords