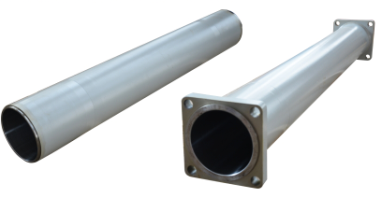

DELIVERY CYLINDER(SCHWING ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1775MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

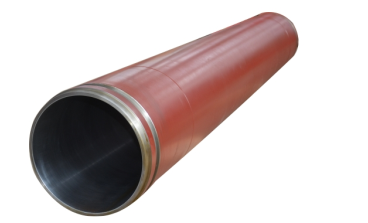

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q:How often should concrete pump accumulators be inspected and replaced?

- Concrete pump accumulators should be inspected at least once a year to ensure their proper functioning and identify any potential issues. However, the frequency of replacement depends on various factors such as usage, maintenance, and the manufacturer's recommendations. It is recommended to consult the equipment manual or contact the manufacturer for specific guidelines on replacement intervals.

- Q:How often should carbide wear plates be replaced in a concrete pump?

- The frequency of replacing carbide wear plates in a concrete pump depends on various factors such as the quality of the carbide, the amount of usage, and the conditions in which the pump operates. Generally, carbide wear plates may need replacement every 6 to 12 months, but regular inspection and monitoring of their condition is essential to determine the actual replacement interval.

- Q:What are the performance characteristics of concrete pump?

- Wear resistant alloy glasses plate and floating cutting ring, long service life

- Q:How can a damaged concrete pump piston affect the pumping efficiency?

- A damaged concrete pump piston can significantly affect the pumping efficiency by compromising the seal between the piston and cylinder. This can lead to leakages and loss of pressure, resulting in reduced pumping force and efficiency. Additionally, a damaged piston can cause irregular movements and vibrations, leading to instability and potential damage to other components of the pump. Overall, a damaged concrete pump piston can hinder the smooth flow of concrete, decrease output, and require more energy to operate, ultimately affecting the pumping efficiency.

- Q:How can a faulty water pump affect the concrete pumping operation?

- A faulty water pump can adversely affect the concrete pumping operation in various ways. Firstly, the water pump is responsible for supplying water to the concrete mix, which helps in maintaining the correct consistency and hydration of the concrete. If the water pump is faulty and not functioning properly, it may result in inadequate water supply, leading to an improper mix ratio and compromised quality of the concrete being pumped. Additionally, a faulty water pump may cause interruptions or delays in the pumping process. If the pump fails, it can halt the entire operation until the issue is resolved or a backup pump is brought in. This can result in project delays, increased labor costs, and potential concrete setting issues if the concrete remains stagnant for an extended period. Furthermore, a faulty water pump can also impact the overall efficiency and productivity of the concrete pumping operation. With reduced or inconsistent water supply, the pumping equipment may experience increased wear and tear, resulting in more frequent breakdowns and maintenance requirements. This not only leads to additional costs but also hampers the smooth flow of work. In summary, a faulty water pump can have significant consequences on a concrete pumping operation, affecting the quality of the concrete mix, causing delays, and decreasing overall efficiency. Thus, it is crucial to regularly inspect and maintain water pumps to ensure their proper functioning.

- Q:How often should hopper grate handles be inspected or replaced in a concrete pump?

- Regular inspections should be conducted on hopper grate handles in a concrete pump to identify any signs of wear and tear or damage. The frequency of these inspections and the need for replacement may vary depending on the equipment's usage and condition. It is suggested that the hopper grate handles be inspected at least once a month or after every 500 hours of operation, whichever occurs first. During the inspection, it is important to verify that the handles are firmly attached to the hopper grate and to examine them for any cracks, bends, or other structural problems. If any damage is detected, it is recommended to promptly replace the handles to prevent accidents or further harm to the equipment. It is also crucial to adhere to the manufacturer's guidelines and recommendations for the maintenance and replacement of hopper grate handles. By regularly inspecting and replacing the handles as necessary, the safe and efficient operation of the concrete pump can be ensured.

- Q:What are the signs of a malfunctioning concrete pump control valve?

- There are various indications that a concrete pump control valve is malfunctioning. Some of the most frequently observed signs are as follows: 1. Concrete flow inconsistency or unevenness: A malfunctioning control valve can cause concrete to flow in an irregular manner, resulting in uneven distribution or even complete cessation of flow. 2. Fluctuating pressure: When the control valve is not functioning properly, it can cause pressure fluctuations in the concrete pump. This can lead to inconsistent output and potential damage to the pump or other components. 3. Heightened noise levels: An improperly functioning control valve can generate unusual or excessive noise during operation. This may indicate internal issues or improper valve functioning. 4. Leakage or dripping: The presence of leaks or drips around the valve or its connections is another indication of a malfunctioning control valve. This can suggest seal failure or other problems that require attention. 5. Difficulties in pump control: When the control valve is not operating correctly, it can become challenging to control the pump's operations. This can include problems with starting or stopping the pump, as well as controlling the speed and direction of concrete flow. 6. Increased energy consumption: A malfunctioning control valve may result in heightened energy consumption as the pump compensates for the valve's inefficiencies. This can lead to higher operating costs and reduced overall efficiency. If any of these signs are observed, it is crucial to address the issue promptly. Malfunctioning control valves can lead to costly repairs, downtime, and potential safety hazards. It is advisable to consult a professional technician or service provider who can diagnose and resolve the problem.

- Q:Can I get spare parts for concrete pump hopper agitators and vibrators?

- Generally, spare parts for concrete pump hopper agitators and vibrators can be easily found. These components are readily available from various manufacturers and suppliers who specialize in construction equipment and machinery. To check for availability and pricing, it is advisable to reach out to the concrete pump manufacturer or their authorized dealer. Another option is to explore online platforms and marketplaces that offer a diverse selection of spare parts for construction equipment, including concrete pump components. To ensure compatibility and optimal performance, it is crucial to provide detailed information about the make and model of the concrete pump when purchasing spare parts.

- Q:How does a concrete pump clamp work?

- A concrete pump clamp is a device used to secure and hold the different components of a concrete pump system together during operation. It acts as a connector between the pipes, hoses, and couplings in the system, ensuring a tight and leak-free connection. The clamp generally consists of two halves that are tightened together using bolts, creating a strong grip around the components. This tight grip prevents any movement or separation of the pipes and hoses, allowing for efficient and safe concrete pumping.

- Q:How can I extend the lifespan of my concrete pump spare parts?

- There are several ways to extend the lifespan of your concrete pump spare parts. 1. Regular maintenance: Develop a maintenance schedule and stick to it. This includes cleaning, lubricating, and inspecting the parts for any signs of wear or damage. Replace any worn-out parts promptly to prevent further damage. 2. Proper storage: Store your spare parts in a clean and dry environment to prevent rust and corrosion. Keep them away from moisture, extreme temperatures, and direct sunlight. 3. Use quality parts: Invest in high-quality spare parts from reputable manufacturers. These parts are usually more durable and have a longer lifespan compared to cheaper alternatives. 4. Follow manufacturer guidelines: Always follow the manufacturer's guidelines for operating and maintaining your concrete pump. This ensures that you use the spare parts correctly and minimize the risk of premature wear. 5. Train operators: Properly train your operators on the correct usage and handling of the concrete pump and its spare parts. This reduces the chances of accidental damage caused by improper operation. By implementing these practices, you can significantly extend the lifespan of your concrete pump spare parts and maximize their performance and efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DELIVERY CYLINDER(SCHWING ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1775MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords