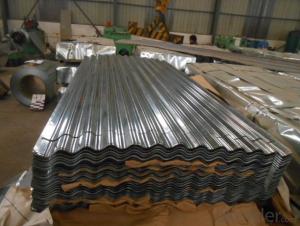

CORRUGATED HOT DIPPED GALVANIZED STEELSHEETS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORRUGATED HOT DIPPED GALVANIZED STEEL SHEETS

THICKNESS TOLERANCE: (+/-0.01mm)

ZINC COATING: 50g/m2 (+/-10g/m2)

WIDTH: 900mm (0/+5mm; AFTER FORMING)

STANDARD:JIS G 3302, SGCH

SURFACE:REGULAR SPANGLE, CHROMATED, DRY

PACKAGE: 2- 3 TON/PALLET

SPECS: 0.18mm X 900mm X 2000mm

Specifications

1. Zinc coating :60-180g( as required)

2. thickness:0.14-0.80mm

3. width:700-1250mm( 750mm,900mm,1215mm,1250mm,1000mm the most common)

6. surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7.application: with excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Package:Standard seaworthy export packing: 3 layers of packing, inside is

kraft paper, water plastic film is in the middle and outside GI steel

sheet to be covered by steel strips with lock.

- Q:What are the main applications of steel sheets?

- Steel sheets have a wide range of applications, including construction projects, automotive manufacturing, shipbuilding, appliance production, and industrial machinery. They are used for structural components, such as beams and columns, as well as for cladding, roofing, and flooring. Additionally, steel sheets are utilized in the production of various consumer goods, such as furniture, containers, and electrical appliances.

- Q:Can steel sheets be used for manufacturing machinery parts?

- Indeed, machinery parts can be manufactured using steel sheets. Steel, as a material, possesses remarkable versatility and durability, thereby offering exceptional strength and rigidity necessary for the production of diverse machinery components. The malleability, ease of cutting, and weldability of steel sheets enable the creation of intricate shapes and structures essential for machinery parts. Furthermore, steel exhibits commendable resistance against corrosion, guaranteeing the longevity of the machinery components. Moreover, steel sheets ensure dimensional stability and can endure substantial loads and elevated temperatures, rendering them a perfect selection for the manufacturing of machinery parts.

- Q:What is the thickness of the steel sheets?

- The thickness of the steel sheets is typically measured in millimeters or gauge, and it can vary depending on the specific application or industry standards.

- Q:Can steel sheets be laminated with other materials?

- Yes, steel sheets can be laminated with other materials. Lamination is a process where multiple layers of materials are bonded together to create a composite structure. Steel sheets can be laminated with various materials such as plastics, polymers, wood, or other metals, depending on the desired properties and application requirements. This lamination process enhances the strength, durability, and overall performance of the steel sheets.

- Q:Can steel sheets be customized in terms of size and shape?

- Yes, steel sheets can be customized in terms of size and shape. They can be cut, bent, or formed to meet specific size requirements or to achieve desired shapes for various applications.

- Q:What is the difference between stainless steel and regular steel sheets?

- Stainless steel and regular steel sheets have distinct differences in their composition and properties. Stainless steel is an alloy comprising iron, chromium, and other elements like nickel and molybdenum. In contrast, regular steel is predominantly made of iron with small amounts of carbon and impurities. The primary disparity between stainless steel and regular steel sheets lies in their corrosion resistance. Due to the presence of chromium, stainless steel exhibits high resistance to corrosion. When exposed to oxygen, chromium forms a protective layer called a passive film on the surface of the steel, preventing rust formation. This makes stainless steel suitable for applications in environments with moisture or chemical exposure. On the other hand, regular steel sheets are susceptible to corrosion as they lack the protective chromium layer. To enhance their corrosion resistance, they may require additional coatings or treatments. Without proper protection, regular steel sheets can rust and deteriorate when exposed to moisture or corrosive substances. Strength and hardness are additional distinguishing factors between stainless steel and regular steel sheets. Stainless steel, with its alloy composition, is generally stronger and more durable than regular steel. It can withstand higher temperatures and has better resistance to wear and tear. Regular steel, while strong, may not offer the same level of strength and durability as stainless steel. Aesthetic appeal is another contrasting aspect. Stainless steel sheets have a shiny, reflective surface, imparting a modern and sleek appearance. They are commonly used in architectural and decorative applications where visual appeal is desired. Regular steel sheets, on the other hand, have a more dull and matte finish and are primarily utilized for structural and industrial purposes rather than for their visual appeal. In conclusion, stainless steel sheets surpass regular steel sheets in terms of corrosion resistance, strength, and aesthetic appeal. They are the preferred choice for applications where durability, hygiene, and maintenance-free performance are essential, such as in kitchens, medical equipment, automotive parts, and construction projects. Regular steel sheets, although less expensive, may require additional protective measures and are commonly employed in structural and industrial applications where corrosion resistance and visual appeal are not primary concerns.

- Q:How are steel sheets priced?

- Steel sheets are typically priced based on factors such as the type and grade of steel used, the size and thickness of the sheet, market demand and supply, and any additional processing or finishing required.

- Q:Can the steel sheets be easily drilled for fastening purposes?

- Yes, steel sheets can be easily drilled for fastening purposes.

- Q:What is the typical thickness tolerance of a steel sheet?

- The typical thickness tolerance of a steel sheet can vary depending on the specific grade of steel and the manufacturing process used. However, in general, the typical thickness tolerance for a steel sheet is around ±0.005 to ±0.010 inches.

- Q:What is the difference between a HRPO and HRSPO steel sheet?

- The main difference between a HRPO (Hot Rolled Pickled and Oiled) and HRSPO (Hot Rolled Skin Pass) steel sheet lies in the manufacturing process and the resulting properties of the two types of sheets. HRPO steel sheets are produced by hot rolling a steel slab and then subjecting it to a pickling process where the surface scale is removed using an acid bath. After pickling, the steel sheet is then oiled to provide a protective coating. The pickling process imparts a clean, smooth surface to the sheet, while the oiling helps prevent corrosion and improve formability. HRPO sheets are typically used in applications that require good surface finish and paintability. On the other hand, HRSPO steel sheets undergo an additional skin pass rolling process after pickling and oiling. This process involves passing the sheet through a set of rolls to further improve its surface quality, resulting in a smoother and more uniform surface finish compared to HRPO sheets. The skin pass process also imparts better flatness and dimensional accuracy to the sheet. HRSPO sheets are commonly used in applications that demand higher surface quality, such as automotive panels, appliances, and electrical enclosures. In summary, while both HRPO and HRSPO steel sheets are pickled and oiled, the additional skin pass rolling step in the manufacturing process of HRSPO sheets enhances their surface quality, flatness, and dimensional accuracy, making them suitable for more demanding applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CORRUGATED HOT DIPPED GALVANIZED STEELSHEETS

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords