Concrete Pump Truck Parts Bend ZX-HD DN125 R1000 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump elbows have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Adopt high chromium and manganese as standard material, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.Two production lines, wear-resistant pipe 100pcs daily, trailer pipe 400pcs daily.

2. The experiment done abroad shows that the life of our concrete pump pipes can reach 6000-15000cbm,got the customers' praise. Uniform baking finish.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. Normal and female/male flanges are both available to suit for normal or high pressure concrete pumping

5. OEM service available.

6. Fitting to PUTZMEISTER, SCHWING Sany, Zoomlion concrete pumps

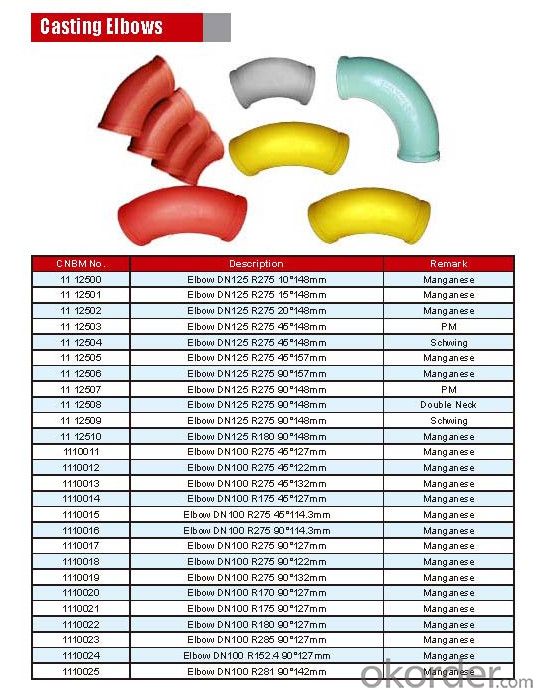

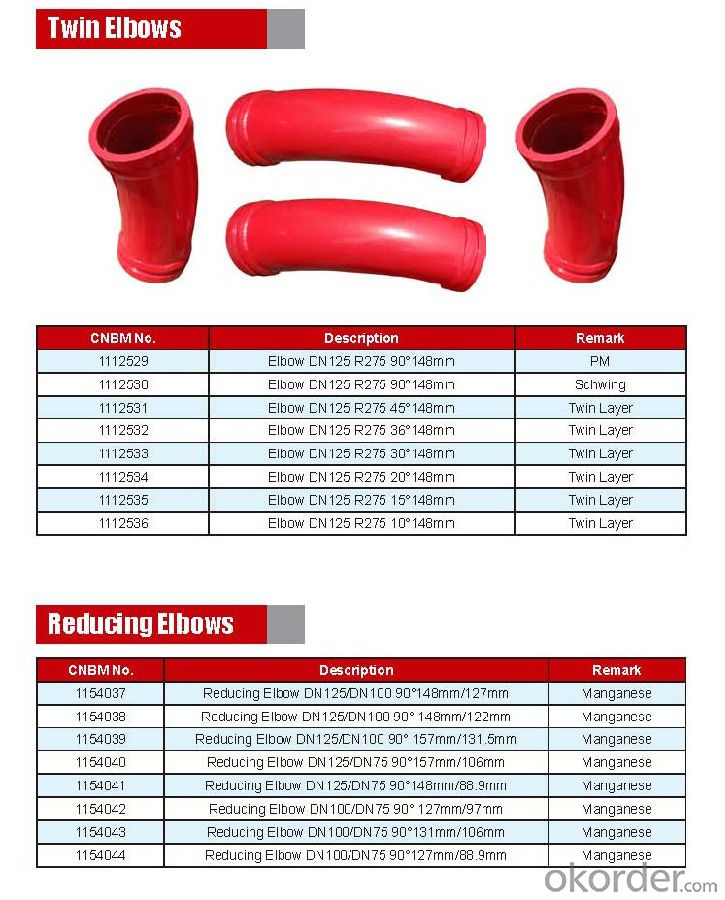

Product Specifications:

Technical: Casting

Radius: 1000mm

Degree: 45

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q:What are the signs of a damaged or malfunctioning electric motor?

- Some signs of a damaged or malfunctioning electric motor may include unusual noises such as grinding or screeching, overheating, excessive vibration, sudden power loss or fluctuations, and a burning smell.

- Q:What is the role of a concrete pump hopper grate pin retainer?

- The safety and functionality of a concrete pump heavily rely on a concrete pump hopper grate pin retainer. Its main function is to secure the grate pins, thereby firmly holding the hopper grate in position. The hopper grate serves as a crucial element in a concrete pump as it acts as a barrier, preventing the entry of debris or foreign objects into the hopper. This is important to avoid any potential damage to the pump or interference with the concrete mixing process. The grate pins, located on the sides of the hopper, contribute to the secure placement of the grate. Specifically designed for the pumping operation, the concrete pump hopper grate pin retainer ensures the firmness of the grate pins, preventing them from becoming loose or dislodged. This guarantees the continuous stability of the grate, keeping the hopper free from unwanted materials and ensuring a smooth and uninterrupted flow of concrete. Moreover, the pin retainer plays a significant role in minimizing the occurrence of accidents or injuries. It reduces the risk of the grate coming loose or falling off during operation. This aspect is particularly crucial in construction sites or other high-risk environments where the utmost importance is given to the safety of workers and equipment. To sum up, the concrete pump hopper grate pin retainer provides stability and security to the hopper grate by firmly holding the grate pins in place. It supports the smooth functioning of the concrete pump by preventing debris from entering the hopper and maintains a safe working environment by reducing the risk of accidents or injuries.

- Q:What are the common issues that require replacement of concrete pump spare parts?

- Concrete pumps can experience various issues that necessitate the replacement of spare parts. One prevalent problem is the gradual deterioration of pump components due to wear and tear. Continuous movement of concrete through the pump causes deterioration of parts like the piston, wear plate, and seals, which then need to be replaced. Another issue that may arise is blockages or clogs in the pump line. This occurs when hardened concrete or other debris accumulates, obstructing the flow of concrete. In such cases, replacing parts like the delivery pipe, hose, or even the entire pump line becomes necessary to ensure proper functioning. Leaks are also a common problem in concrete pumps. These leaks often result from damaged or worn-out seals, gaskets, or O-rings. If left unattended, leaks can lead to reduced pump performance and potential safety hazards. Replacing the affected parts helps prevent further damage and ensures efficient pump operation. Additionally, pump malfunctions can be attributed to electrical or mechanical issues. Faulty electrical components, such as switches or sensors, may require replacement to restore proper functionality. Mechanical problems, such as a worn-out gearbox or a malfunctioning hydraulic system, may also necessitate the replacement of specific pump parts. In summary, common issues that call for the replacement of concrete pump spare parts include wear and tear, blockages, leaks, electrical malfunctions, and mechanical failures. Regular maintenance and inspection of the pump enable early identification of these issues, allowing for timely replacement of the necessary spare parts to maintain smooth pump operation.

- Q:What are the different types of concrete pump hopper cylinders?

- There are primarily two types of concrete pump hopper cylinders: single-acting cylinders and double-acting cylinders. Single-acting cylinders have only one piston that pushes the concrete out of the hopper. On the other hand, double-acting cylinders have two pistons, one for pushing the concrete out and the other for bringing it back into the hopper.

- Q:What are the advantages of using carbon fiber components in concrete pump spare parts?

- There are several advantages of using carbon fiber components in concrete pump spare parts. Firstly, carbon fiber is extremely lightweight yet incredibly strong, which allows for reduced weight and increased durability of the spare parts. This not only makes them easier to handle and transport, but also enhances their overall performance and longevity. Secondly, carbon fiber has a high resistance to corrosion and chemicals, making it highly suitable for use in concrete pumping applications where exposure to various substances is common. This significantly extends the lifespan of the spare parts, reducing maintenance and replacement costs in the long run. Additionally, carbon fiber components offer improved fatigue and impact resistance, ensuring they can withstand the demanding conditions and high stresses involved in concrete pumping operations. This enhances the reliability and safety of the equipment, minimizing the risk of failure or breakdown during use. Furthermore, carbon fiber has excellent thermal and electrical insulation properties, reducing heat transfer and the risk of electrical conductivity. This makes it ideal for use in concrete pump spare parts that operate in extreme temperatures or are exposed to electrical currents, enhancing their overall performance and safety. In summary, the advantages of using carbon fiber components in concrete pump spare parts include lightweight yet strong construction, high resistance to corrosion and chemicals, improved fatigue and impact resistance, as well as enhanced thermal and electrical insulation properties.

- Q:Are there any specific cleaning procedures for concrete pump spare parts?

- Yes, there are specific cleaning procedures for concrete pump spare parts. It is recommended to clean the parts with water and a mild detergent to remove any dirt or debris. It is important to avoid using harsh chemicals or abrasive materials that may damage the parts. Additionally, regular maintenance and lubrication of the parts is essential to ensure their optimal performance and longevity.

- Q:Can I get spare parts for both piston and rotary concrete pumps?

- Yes, you can get spare parts for both piston and rotary concrete pumps. Many manufacturers and suppliers offer a wide range of spare parts for these types of pumps. These parts include but are not limited to pistons, seals, valves, wear plates, hydraulic components, and bearings. It is important to ensure that you purchase genuine spare parts from reputable suppliers to ensure the quality and compatibility with your specific pump model. Additionally, it is recommended to have a regular maintenance and inspection schedule for your concrete pump to identify any worn-out parts and replace them promptly to avoid any potential breakdowns or disruptions in your construction projects.

- Q:Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Yes, it is possible to get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve. Concrete pump manufacturers and suppliers usually offer a wide range of spare parts for their equipment, including valves. These spare parts can be ordered directly from the manufacturer or through authorized distributors. It is important to provide specific information about the concrete pump model, valve type, and any other relevant details when ordering spare parts to ensure compatibility. Additionally, there are specialized companies that focus on supplying spare parts for concrete pumps, regardless of the valve system type. These companies often have a comprehensive inventory of spare parts and can assist in identifying and sourcing the required parts for your specific concrete pump.

- Q:What is the function of a concrete pump hydraulic accumulator?

- The operation of a concrete pump heavily relies on a crucial component known as the hydraulic accumulator. Its primary objective is to store and release hydraulic energy, which is instrumental in maintaining a seamless and uninterrupted flow of concrete during pumping activities. The hydraulic accumulator acts as a reservoir for pressure, being directly connected to the hydraulic system of the concrete pump. When the pump is not actively engaged, the accumulator stores hydraulic fluid that is pressurized. This accumulated energy can be unleashed when necessary, particularly during the pumping process, effectively providing supplementary power to the main hydraulic system. During concrete pumping, the accumulator proves invaluable in upholding a steady stream of concrete by compensating for any fluctuations in hydraulic system pressure. It functions as a buffer, absorbing any excessive pressure and subsequently releasing it back into the system whenever required. This mechanism is pivotal in averting sudden surges or drops in pressure, which could potentially lead to irregular concrete flow or even inflict damage upon the pump. Moreover, the hydraulic accumulator also contributes to reducing energy consumption and optimizing the overall efficiency of the concrete pump. By storing and reusing energy, it diminishes the reliance on a constant power supply from the primary hydraulic system, subsequently easing the burden on the pump's engine and enhancing fuel efficiency. To summarize, the concrete pump hydraulic accumulator serves the paramount purpose of storing and releasing hydraulic energy, guaranteeing a consistent and uninterrupted flow of concrete during pumping activities. Additionally, it plays a significant role in energy efficiency and safeguarding the pump from potential harm.

- Q:How can the concrete pump pipe be cleaned?

- Take some concrete out of the first straight pipe and connect with the air wash joint. The joint shall be filled with sponge balls soaked in water. The inlet, the exhaust valve and the compressed air hose shall be installed on the joint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pump Truck Parts Bend ZX-HD DN125 R1000 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords