Colored Metallic Yarn With High Quality From China

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 MT m.t.

- Supply Capability:

- 15MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification Of Colored Metallic Yarn With High Quality From China

1 Thickness : 12 micron, 23micron,30 micron,50micron

2 Color : Golden, Slivery,Green,Blue,Yellow etc.

3 Material : cutting aluminum-plated and dyed polyester films

4 Technics : Ring Spun

5 Style: M-Type

6 Package : net weight 300g/bobbin ,64bobbins/carton

19.2kilo/carton . one 20 GP can contain 545cartons = 10464 kg

Feature Of Colored Metallic Yarn With High Quality From China

High Tenacity, Anti-Pilling

Application Of Colored Metallic Yarn With High Quality From China

Sewing, Knitting, Weaving

Usuage Of Colored Metallic Yarn With High Quality From China

Sewing, Hand Knitting, Knitting, Weaving

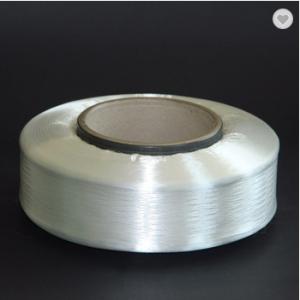

Pictures Of Colored Metallic Yarn With High Quality From China

- Q:What is the difference between textile sizing and paper making?

- The modified starch used in papermaking is mainly: acid modified starch (surface sizing), oxidized starch (surface sizing, coating), phosphate starch (surface sizing, coating), oxidized acetate starch (coating) Cationic starch, amphoteric starch (pulp added), grafted starch (coated. Market less) a technology is not up to standard, and then a cost can not accept

- Q:What is the reason for the low strength of cotton yarn

- We have experimented with the increase in the twist of the tube after passing through the windings, and the control of the normal spun yarns is about 340-350.

- Q:What are the types of cotton yarns?

- (5) according to the use of yarn points: ① warp yarn is woven in the direction of parallel cloth in the direction of the yarn, a greater strength, the general twist; ② weft yarn is woven in the vertical direction of the yarn, Strong requirements lower than the warp yarn, twist is generally lower than the warp, to maintain a certain degree of softness; ③ knitting yarn is required to clean, uniform, twist small, to prevent damage in the knitting caused by broken; ④ industrial yarn such as tire cord, Conveyor belt yarn, health medicine yarn.

- Q:Textile spinning workshop car car summary and plan

- Summary must have a brief overview of the situation and narrative, some relatively simple, some more detailed. Achievements and shortcomings. This is the main content of the summary. The purpose of the summary is to be sure to score and find out the shortcomings. What are the results, how big, what aspects of performance, how to obtain; the number of shortcomings, in what areas, how to produce, should be written clearly.

- Q:40s / 2 What does it mean, is this yarn 40 or 80?

- We love the veil is dedicated to do the cotton yarn, so I give you the answer is that 40 2 shares of yarn, the two lines are 40, that is, 20 per share

- Q:Calculation formula of yarn twist

- Yarn twist refers to the yarn to have a certain strength, elasticity, elongation, gloss, feel and other physical and mechanical properties, must be twisted by changing the yarn, the fiber structure to achieve yarn twist, in fact, is the use of cotton yarn cross-section To produce a relative angular displacement, so that the original straight parallel fibers and yarn shaft tilt to change the yarn structure

- Q:What is the yarn inside the textile industry is what kind of yarn?

- As for the thickness of the yarn, is to rely on weighing to determine. And the twist of the yarn, measured with a twist meter

- Q:What is the number of yarns used in cotton textiles to mean what is meant

- When the fibers are spun into yarn, they can be woven into a fabric. Because the weaving machine used in the principle of the machine is different, weaving the fabric of the internal structure is different. Usually can be divided into two categories of woven and knitted.

- Q:What are the benefits of the steaming machine to the textile industry?

- (4) knitting process, the coil forming uniform; (5) the size of the finished product size and stability; (6) no additional humidification system; (7) to eliminate static electricity.

- Q:Textile spinning mill management system

- The cube net table in this regard is done in place, both from the supplier, procurement, production, to sales, are able to provide timely data and synchronization, can make the various departments of the staff through the query can understand their own The information and circumstances required.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | North America, South America, Western Europe, eastern Europe, east Asia, central Asia, southeast Asia, the Middle East, Africa, Oceania |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Colored Metallic Yarn With High Quality From China

- Loading Port:

- Ningbo Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 MT m.t.

- Supply Capability:

- 15MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords