Color Corrugated Steel Roof Panels in Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

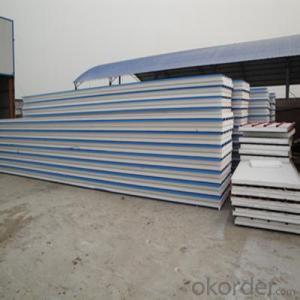

High Quality Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How to guarantee the quality of the products?

4) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5) How long can we receive the product after purchase?

6) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel sheets are commonly used in construction for their strength and durability, making them suitable for supporting the load requirements of mezzanine floors. They can provide a solid and stable surface for various applications, such as storage or additional workspace.

- Q:How thick are steel sheets available?

- A wide variety of thicknesses can be found for steel sheets, catering to the specific needs of each application. Steel sheets commonly come in thicknesses ranging from 0.5mm (or 0.020 inches) up to several inches. Gauge is typically used to measure the thickness of steel sheets, with lower gauge numbers indicating thicker sheets. Nevertheless, it's worth mentioning that the availability of steel sheets in particular thicknesses might differ depending on the supplier and the type of steel employed.

- Q:Can steel sheets be used for manufacturing jewelry?

- Yes, steel sheets can be used for manufacturing jewelry, particularly for creating industrial or bold statement pieces. However, due to its durability and heaviness, steel sheets are not commonly used for traditional or delicate jewelry designs.

- Q:What is the yield strength of steel sheets?

- The yield strength of steel sheets can vary depending on the specific grade and thickness, but typically ranges between 250 and 400 megapascals (MPa).

- Q:What is the average cost of steel sheets per square foot?

- The average cost of steel sheets per square foot can vary depending on factors such as thickness, quality, and market conditions. It is recommended to contact suppliers or conduct research to get the most accurate and up-to-date pricing information.

- Q:Can steel sheets be used for insulation?

- Steel sheets are not suitable for insulation as they lack the ability to retain heat or prevent effective heat transfer due to their good conductivity of heat and electricity. Instead, steel sheets can even conduct heat and cold, rendering them ineffective as insulators. On the other hand, materials like fiberglass, foam, or cellulose are far superior for insulation as they excel at trapping and preventing the transfer of heat, making them the ideal choice for insulation purposes.

- Q:Can steel sheets be used for playground equipment?

- Yes, steel sheets can be used for playground equipment. Steel is a highly durable and strong material that can withstand heavy use and harsh weather conditions, making it suitable for playground structures such as climbing frames, slides, and swings. Additionally, steel sheets can be shaped and formed into various designs, offering flexibility in creating engaging and safe play structures for children.

- Q:How do steel sheets perform in thermal expansion?

- Steel sheets have a relatively low coefficient of thermal expansion, meaning they expand and contract less compared to many other materials when exposed to changes in temperature. This property makes steel sheets a suitable choice for applications where thermal stability and minimal dimensional changes are required.

- Q:What is the typical coefficient of thermal expansion of a steel sheet?

- Steel sheets typically have a coefficient of thermal expansion of approximately 10-12 ppm/°C. This signifies that for every degree Celsius rise in temperature, the steel sheet will expand uniformly in all directions by 10-12 ppm. However, it is crucial to acknowledge that the coefficient of thermal expansion may differ based on the precise type and composition of the steel. Various steel alloys may exhibit slightly varied coefficients, although the range of 10-12 ppm/°C is widely accepted as the average.

- Q:What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets compared to fiberglass can vary depending on various factors. Generally, steel sheets tend to be more expensive than fiberglass sheets. This is mainly due to the higher cost of raw materials and the manufacturing process involved in producing steel sheets. Additionally, steel sheets are known for their durability and strength, making them a popular choice for applications where strength and resistance to impact or harsh weather conditions are required. On the other hand, fiberglass sheets are typically less expensive due to the lower cost of raw materials and the simpler manufacturing process. Fiberglass sheets are commonly used in applications where weight and corrosion resistance are important factors, such as in the construction of boats or aircraft. However, it is important to note that the cost of steel sheets compared to fiberglass can also be influenced by market fluctuations, availability, and specific requirements of the project. Therefore, it is recommended to obtain quotes and compare prices from suppliers to get an accurate understanding of the average cost in a given context.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Corrugated Steel Roof Panels in Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords