Cold Rolled Steel Coils 304,Cold Rolled Steel Plates 316 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

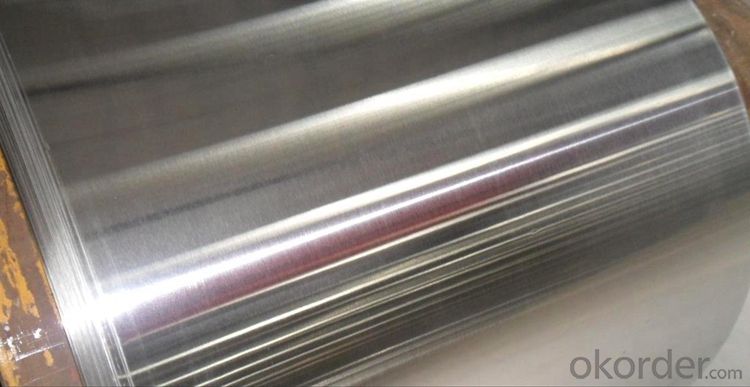

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Stainless steel plate laser cutting how to charge?

- It depends on which laser machine you use, and the specific model, and the processing materials are also different. Consumption is mainly: electricity, laser gas, auxiliary gas, consumables, general machine tool software has billing function, but not allowed.

- Q:How do you remove adhesive from stainless steel sheets?

- One effective way to remove adhesive from stainless steel sheets is by applying a small amount of rubbing alcohol or acetone to a soft cloth and gently rubbing the adhesive residue. Another option is to use a mixture of warm water and mild soap, followed by scrubbing with a non-abrasive sponge or cloth. If the adhesive is particularly stubborn, using a commercial adhesive remover specifically designed for stainless steel can also be effective.

- Q:Can stainless steel sheets be used for fermentation tanks?

- Fermentation tanks can indeed utilize stainless steel sheets. The reason behind this preference lies in stainless steel's durability, resistance to corrosion, and capability to maintain the desired temperature. Its non-reactive nature guarantees the purity and quality of the product by preventing any interaction with the fermenting substances. Furthermore, stainless steel's easy-clean and sanitize properties are vital in ensuring hygienic conditions throughout the fermentation process. On top of all that, stainless steel sheets can be shaped and sized according to specific requirements for fermentation tanks. Consequently, stainless steel sheets are a dependable and popular choice in multiple industries, including brewing, winemaking, and food processing.

- Q:What is the fatigue strength of stainless steel sheets?

- The fatigue strength of stainless steel sheets may differ based on various factors, including the specific grade of stainless steel, the manufacturing process, the surface finish, and the testing conditions. Generally, stainless steel sheets exhibit high fatigue strength due to their inherent properties, such as their ability to withstand cyclic loading and their resistance to corrosion. Typically, the fatigue strength of stainless steel sheets is measured in terms of stress amplitude (σa) or stress range (σr), indicating the level of stress the material can endure for a specific number of cycles before failure. Fatigue testing is often conducted to determine this, involving subjecting the material to repeated cyclic loading until it fails. The number of cycles required for failure is referred to as the fatigue life. Different grades of stainless steel possess varying fatigue strengths, with higher grades usually demonstrating greater resistance to fatigue. Austenitic stainless steels like 304 and 316, for example, exhibit excellent fatigue strength and are commonly employed in applications with significant cyclic loading, including structural components and automotive parts. The fatigue strength of stainless steel sheets can also be impacted by surface finish. Inadequate surface conditions, such as scratches, notches, or roughness, can act as stress concentrators and decrease fatigue strength. Hence, it is essential to ensure that stainless steel sheets possess a smooth and defect-free surface to maximize their resistance to fatigue. Additionally, environmental factors like temperature, humidity, and corrosive substances can influence the fatigue strength of stainless steel sheets. Elevated temperatures and aggressive environments can decrease the fatigue life of stainless steel. Therefore, it is crucial to consider these factors when designing for fatigue resistance. To summarize, the fatigue strength of stainless steel sheets is generally high due to their inherent properties. However, it can vary depending on factors such as the grade of stainless steel, surface finish, and environmental conditions. Conducting fatigue testing and considering these factors during the design process can help guarantee the optimal performance and durability of stainless steel sheets in applications involving cyclic loading.

- Q:Can stainless steel sheets be bent or formed without cracking?

- Yes, stainless steel sheets can be bent or formed without cracking, as they have high ductility and excellent formability properties.

- Q:What is the fire resistance rating of stainless steel sheets?

- Stainless steel sheets lack an inherent fire resistance rating as they are not naturally fire resistant materials. Nevertheless, stainless steel can demonstrate commendable fire resistance attributes due to its high melting point and low thermal conductivity. Consequently, stainless steel sheets are less prone to melting or transferring heat during a fire, thus impeding the spread of flames. Furthermore, stainless steel possesses corrosion resistance, which further bolsters its performance in fire scenarios. However, it should be emphasized that the fire resistance of a structure or system hinges on a combination of diverse factors, encompassing the comprehensive design, construction, and utilization of fire-resistant materials. Consequently, the fire resistance rating of stainless steel sheets may fluctuate depending on the specific application and the overarching fire protection measures implemented.

- Q:Are stainless steel sheets resistant to heat and high temperatures?

- Stainless steel sheets possess exceptional resistance to heat and high temperatures. Their remarkable heat resistance properties enable them to maintain both their strength and structural integrity even under extreme temperature conditions. Consequently, stainless steel sheets are highly suitable for a diverse range of applications that involve heat and high temperatures. These applications include industrial furnaces, boilers, heat exchangers, and automotive exhaust systems. Stainless steel is capable of enduring temperatures of up to 1200 degrees Celsius (2192 degrees Fahrenheit) without compromising its structural properties, rendering it a favored option in industries requiring materials that can withstand intense heat. Furthermore, stainless steel also exhibits excellent resistance to oxidation, thereby preventing the formation of rust or scale when exposed to high temperatures for extended durations. In sum, stainless steel sheets serve as an exceptional choice for applications necessitating resistance to heat and high temperatures.

- Q:How do you prevent galvanic corrosion when using stainless steel sheets?

- To prevent galvanic corrosion when using stainless steel sheets, there are several measures you can take: 1. Avoid direct contact with dissimilar metals: Galvanic corrosion occurs when two different metals come into contact in the presence of an electrolyte, such as moisture. To prevent this, ensure stainless steel sheets are not in direct contact with dissimilar metals, especially those with a higher anodic index, such as aluminum or copper. If contact is unavoidable, use insulating materials like plastic or rubber gaskets to separate the metals. 2. Select compatible fasteners: When fastening stainless steel sheets, it is crucial to choose fasteners made from the same or compatible metals. Using dissimilar metals can create galvanic cells, leading to corrosion. Stainless steel fasteners or those made from materials with similar corrosion resistance, like galvanized steel, are recommended. 3. Use protective coatings: Applying protective coatings to stainless steel sheets can provide an additional barrier against galvanic corrosion. Consider using paint, epoxy, or other appropriate coatings that are compatible with stainless steel. These coatings act as a sacrificial layer, preventing direct contact between the stainless steel and the surrounding environment. 4. Insulate electrical connections: If stainless steel sheets are involved in electrical systems, ensure proper insulation of electrical connections. This prevents the flow of electrical current between dissimilar metals, reducing the risk of galvanic corrosion. Insulating materials like plastic or rubber sleeves can be used to separate the metals and inhibit the formation of galvanic cells. 5. Control environmental factors: Galvanic corrosion is often accelerated in the presence of moisture, saltwater, or acidic environments. Controlling these factors can help prevent corrosion on stainless steel sheets. Regularly clean and dry the sheets, especially in areas where moisture accumulates. Avoid exposing the sheets to saltwater or corrosive chemicals, and maintain proper ventilation to minimize humidity levels. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using stainless steel sheets. However, it is important to regularly inspect the sheets for any signs of corrosion and address them promptly to maintain their integrity and longevity.

- Q:Can stainless steel sheets be used in food processing industries?

- Yes, stainless steel sheets are commonly used in food processing industries due to their excellent corrosion resistance, hygiene, and durability. The smooth and non-porous surface of stainless steel makes it easy to clean and maintain, ensuring sanitary conditions. Additionally, stainless steel is resistant to chemicals and can withstand high temperatures, making it suitable for various food processing applications such as equipment, storage tanks, and work surfaces.

- Q:What is the maximum length available for stainless steel sheets?

- The maximum length available for stainless steel sheets can vary depending on the manufacturer and supplier. However, it is common for stainless steel sheets to be available in lengths of up to 120 inches or 10 feet.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Steel Coils 304,Cold Rolled Steel Plates 316 Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords