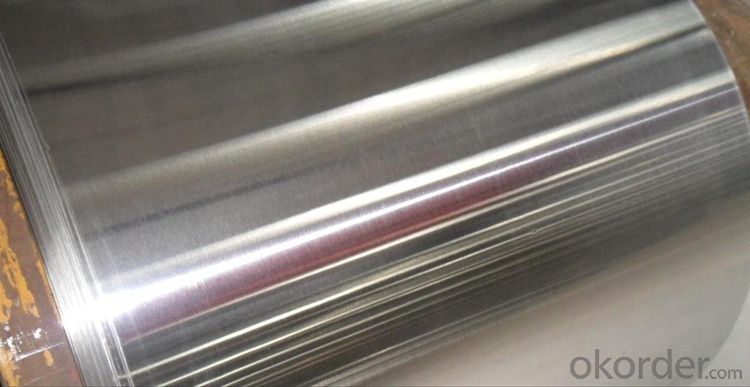

Cold Rolled Stainless Steel Coils,Stainless Steel Plates NO.2B Finish Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Product name: cold roll stainless steel coilcold roll stainless steel coil

Material | Stainless Steel | |

Standard | AISI, ASTM, JIS,GB,EN,DIN | |

Grade | 304 | |

Technology | Cold Rolled and Hot rolled | |

Form | plate | |

Thickness | 0.3 mm – 8.0mm | |

Width | 1000mm,1219mm,1250mm,1500mm,1524mm,2000mm | |

The sizes or thickness of stainless steel coil can be customized, if you need additional information, please don't hesitate to contact us at anytime. | ||

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:Can stainless steel sheets be used for elevator interiors?

- Yes, stainless steel sheets can be used for elevator interiors. Stainless steel is a popular material choice for elevator interiors due to its durability, aesthetic appeal, and ease of maintenance. It is resistant to corrosion, scratches, and stains, making it ideal for high-traffic areas like elevators. Stainless steel sheets can be customized to fit the specific design requirements of the elevator, and they come in a variety of finishes, such as brushed, mirror, or patterned, allowing for a sleek and modern look. Additionally, stainless steel is easy to clean and sanitize, which is especially important in public spaces like elevators where hygiene is a priority. Overall, stainless steel sheets offer a versatile and practical solution for elevator interiors.

- Q:What are the advantages of using stainless steel sheets in the medical industry?

- There are several advantages of using stainless steel sheets in the medical industry: 1. Hygiene and Cleanliness: Stainless steel is a non-porous material, which makes it easy to clean and disinfect. It is resistant to bacteria, mold, and other pathogens, making it an ideal choice for medical equipment, surgical instruments, and even hospital furniture. 2. Durability and Longevity: Stainless steel is highly durable and can withstand harsh conditions, including high temperatures, humidity, and corrosive substances. This ensures that medical equipment and instruments made from stainless steel sheets have a longer lifespan, reducing the need for frequent replacements. 3. Strength and Safety: Stainless steel sheets offer excellent strength and structural integrity, making them suitable for applications that require resistance to impact and pressure. This is crucial in the medical industry, where instruments and equipment undergo constant use and handling. 4. Resistance to Stains and Corrosion: Stainless steel is highly resistant to stains and corrosion, even in aggressive environments. This property is essential in medical facilities where exposure to various chemicals and liquids is common. The resistance to corrosion ensures that stainless steel sheets remain intact and do not release harmful substances into the environment. 5. Aesthetic Appeal: Stainless steel sheets have a sleek and modern appearance that adds to the overall aesthetic appeal of medical equipment and instruments. This can create a positive impression on patients, instilling confidence in the quality and cleanliness of the medical facility. 6. Recyclability: Stainless steel is a sustainable material as it can be recycled without any loss in quality. This reduces the environmental impact of the medical industry by minimizing waste and conserving resources. In conclusion, the advantages of using stainless steel sheets in the medical industry include hygiene, durability, strength, resistance to stains and corrosion, aesthetic appeal, and recyclability. These qualities make stainless steel a reliable and cost-effective choice for medical equipment, instruments, and other applications in healthcare settings.

- Q:Can stainless steel sheets be used for medical equipment?

- Yes, stainless steel sheets can be used for medical equipment. Stainless steel is widely used in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is commonly used for surgical instruments, implants, medical devices, and equipment such as sterilization trays, hospital beds, and operating room tables. Stainless steel is non-reactive, which means it does not interact with body tissues or fluids, making it a safe and hygienic choice for medical applications. Additionally, stainless steel can withstand repeated sterilization processes without losing its properties, making it ideal for use in hospitals and healthcare facilities.

- Q:Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

- Q:What are the different types of stainless steel sheet surface coatings for outdoor applications?

- There are several different types of stainless steel sheet surface coatings that are commonly used for outdoor applications. These coatings are designed to enhance the durability and corrosion resistance of the stainless steel, making it suitable for use in harsh outdoor environments. One of the most common coatings used for outdoor applications is a powder coating. Powder coating is a process in which a dry powder is applied to the stainless steel surface and then cured under heat to form a protective layer. This coating provides excellent resistance to corrosion, UV rays, and chemicals, making it ideal for outdoor use. It also offers a wide range of color options, allowing for customization and aesthetic appeal. Another type of coating commonly used for outdoor applications is a PVD (Physical Vapor Deposition) coating. This process involves the deposition of a thin film of material onto the stainless steel surface through a vacuum chamber. PVD coatings provide excellent adhesion, wear resistance, and corrosion resistance, making them suitable for outdoor applications. They also offer a variety of decorative finishes, such as gold, bronze, or black, which can enhance the appearance of the stainless steel. Additionally, stainless steel can be coated with a ceramic coating for outdoor use. Ceramic coatings are typically applied through a high-temperature spray process, which forms a hard, protective layer on the stainless steel surface. These coatings offer superior resistance to abrasion, chemicals, and UV rays, making them ideal for outdoor applications that require high durability. In summary, the different types of stainless steel sheet surface coatings for outdoor applications include powder coating, PVD coatings, and ceramic coatings. Each of these coatings provides unique benefits in terms of corrosion resistance, durability, and aesthetic appeal, allowing for the use of stainless steel in a wide range of outdoor environments.

- Q:Are stainless steel sheets suitable for desalination plants?

- Yes, stainless steel sheets are suitable for desalination plants. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions found in desalination plants, such as exposure to saltwater and high temperatures. It has excellent durability and mechanical properties, making it ideal for use in various components of desalination plants, including piping, heat exchangers, and tanks. Stainless steel also has good hygiene properties, making it suitable for desalination plants that require strict cleanliness standards. Additionally, stainless steel sheets can be easily fabricated and installed, allowing for efficient construction and maintenance of desalination plants.

- Q:What are the different types of stainless steel sheet surface treatments available?

- There are several types of stainless steel sheet surface treatments available, including brushed, mirror, embossed, and patterned finishes.

- Q:430 stainless steel plate maximum temperature tolerance is how many degrees?

- 430 stainless steel plate, maximum heat resistance is 900 degrees celsius.

- Q:Are stainless steel sheets resistant to erosion corrosion?

- Stainless steel sheets possess a high resistance to erosion corrosion, primarily because of the presence of chromium in the alloy. The chromium forms a protective layer of chromium oxide on the steel's surface, serving as a barrier against oxygen and moisture, thus safeguarding it from corrosion. Moreover, stainless steel sheets also exhibit resistance to erosion corrosion induced by various chemicals and acids. The composition of the alloy, typically containing elements like nickel and molybdenum, augments its ability to withstand corrosion in harsh environments. Consequently, stainless steel sheets find wide-ranging applications, including in industries such as chemical processing, oil and gas, and marine. Nevertheless, it is crucial to recognize that the resistance of stainless steel sheets to erosion corrosion may differ depending on the specific grade or alloy employed. Different grades possess varying levels of corrosion resistance, necessitating the selection of an appropriate grade based on the application's specific environmental conditions and requirements. Regular maintenance and proper handling can further extend the lifespan and uphold the corrosion resistance of stainless steel sheets.

- Q:Can stainless steel sheets be used for medical instrument trays?

- Yes, stainless steel sheets can be used for medical instrument trays. Stainless steel is a common material used in medical settings due to its durability, resistance to corrosion, and ease of cleaning. It is suitable for maintaining a sterile environment and can withstand repeated sterilization processes without degrading.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Stainless Steel Coils,Stainless Steel Plates NO.2B Finish Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords