Climbing Formwork- Formwork- Cantilever

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

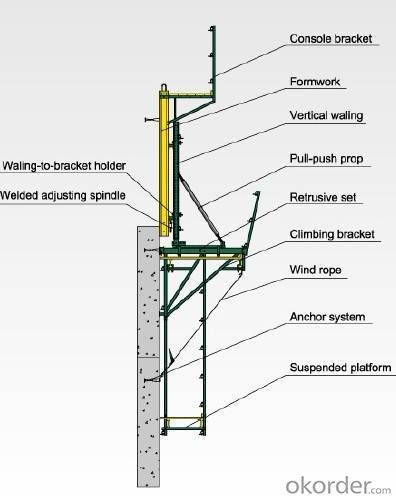

CantileverFormwork is mainly used in the concrete pouring of pier,high buildings, and so on. The concrete lateral pressure is entirely supportedby anchor system and the wall-through tie-rods, additional reinforcement is notneeded. The construction is easy, rapid and economical. A single pouring height is high and thefinished concrete surface is perfect. Cantilever formwork has several types,thestructure is similar, and has its own different characteristic.Canuse them according to actual demand.

Maincantilever Formwork:PJ200 & PJ240,CB-240 etc.

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

- Q:What is the steel plate support

- The steel pipe support system comprises a support rod system and a subsidiary component part, wherein the supporting rod system comprises a main rod, a movable end and a fixed end

- Q:Can steel props be used for supporting temporary military structures?

- Yes, temporary military structures can be supported using steel props. Steel props, also known as adjustable steel props or steel shore props, are widely used in the construction industry to provide support for temporary structures like formwork, scaffolding, and shoring systems. These props are crafted from high-grade steel, which ensures their strength, stability, and durability. In the military context, temporary structures are frequently erected for various purposes, including command centers, field hospitals, barracks, and storage facilities. Steel props are an excellent option for supporting these structures due to their ability to bear heavy loads and be adjusted to the desired height. Their adjustability feature allows them to adapt to different terrain or ground conditions, ensuring stability and safety. Furthermore, steel props possess the advantage of being lightweight and easy to transport, making them suitable for military operations where mobility is crucial. They can be quickly assembled and disassembled, allowing for efficient deployment and relocation of temporary structures as required. Moreover, steel props exhibit resistance to corrosion and adverse environmental conditions, making them suitable for military deployments in diverse climates and terrains. They are capable of withstanding harsh weather conditions such as strong winds, heavy rain, and extreme temperatures. In conclusion, steel props are indeed a viable option for supporting temporary military structures. Their strength, adjustability, mobility, and resistance to environmental factors make them a dependable choice for providing the necessary support and stability required in military operations.

- Q:How do you secure a steel prop in place?

- To secure a steel prop in place, there are a few steps you can follow: 1. Choose the right size and type of steel prop: Ensure that the prop you select is the appropriate size and type for the task at hand. The prop should be able to support the weight and load it will be subjected to. 2. Positioning: Place the steel prop in the desired location, ensuring it is aligned properly and in the correct orientation. Make sure it is positioned on a stable and level surface that can bear the weight. 3. Adjust the height: Extend or retract the prop to the desired height. Most steel props have an adjustable screw mechanism that allows you to adjust the height according to your requirements. 4. Tighten the prop: Once the prop is at the correct height, secure it in place by tightening the locking mechanism. This could involve turning a handle, tightening a nut, or using a locking pin, depending on the specific design of the steel prop you are using. 5. Check stability: After securing the prop, check its stability to ensure it is firmly in place. Give it a gentle shake or push to see if it remains steady. If it wavers or seems unstable, reposition or adjust it until it is secure. 6. Test load-bearing capacity: If your task involves placing a load on the steel prop, it is important to test its load-bearing capacity. Gradually add the load while monitoring the prop's stability. Avoid exceeding the recommended maximum load capacity to prevent any accidents. 7. Regular inspections: Periodically inspect the steel prop to ensure it remains secure and in good condition. Look for any signs of wear, damage, or loosening of the locking mechanism. If any issues are detected, address them promptly to maintain the prop's stability and safety. Following these steps will help you effectively secure a steel prop in place, ensuring stability and safety for your construction or support needs.

- Q:Can steel props be used for temporary support in hydraulic structures?

- Yes, steel props can be used for temporary support in hydraulic structures. Steel props are strong and durable, making them suitable for providing temporary support during construction or maintenance activities in hydraulic structures such as dams, bridges, and canals. They can be easily adjusted to the required height and can withstand heavy loads. Additionally, steel props are resistant to corrosion, which is important in hydraulic structures where they may come in contact with water or moisture. However, it is important to ensure that the steel props are properly designed and installed to provide adequate support and meet the specific requirements of the hydraulic structure.

- Q:What are the common applications of steel props?

- Steel props, also known as adjustable steel props or steel shore props, are widely used in construction and building projects. These props provide temporary support to various structures during construction or renovation. Here are some common applications of steel props: 1. Formwork Support: Steel props are extensively used to support formwork structures during the casting of concrete. They provide stability and load-bearing capacity, ensuring the formwork stays in place until the concrete sets. 2. Slab and Beam Support: Steel props are commonly employed to support slabs and beams during construction. They help distribute the load evenly, preventing any potential sagging or collapsing of the structure. 3. Shoring and Scaffolding: Steel props are an essential component of shoring systems used to stabilize and support excavations, trenches, and walls. They help prevent soil movement and maintain structural integrity during earthworks and foundation construction. 4. Temporary Supports: Steel props are utilized as temporary supports when removing load-bearing walls, columns, or beams during renovation or alterations. They provide a secure and adjustable solution to ensure the remaining structure remains stable while the modifications take place. 5. Temporary Roof Supports: Steel props are commonly used to provide temporary support to roofs during repairs or construction. They help maintain the structural stability of the building, especially in cases where the existing roof structure has been compromised. 6. Mezzanine and Raised Floor Support: Steel props are employed to support mezzanine floors and raised platforms, providing stability and load-bearing capacity. They help distribute the weight of the floor and any additional loads to the foundation or lower level. 7. Pipe and Duct Support: Steel props are used to support pipes, ducts, and other utilities during installation or maintenance. They prevent sagging or movement of these systems, ensuring they are properly aligned and supported. In summary, steel props find wide-ranging applications in construction projects, including formwork support, slab and beam support, shoring and scaffolding, temporary supports, temporary roof support, mezzanine and raised floor support, and pipe and duct support. Their adjustable nature, load-bearing capacity, and versatility make them a reliable choice for providing temporary support during various construction activities.

- Q:Can steel props be used in pipeline construction?

- Yes, steel props can be used in pipeline construction. Steel is a strong and durable material that can provide the necessary support and stability required for pipeline installations.

- Q:Steel support, mixed soil support, calculation method?

- There are many kinds of support, you said, according to the points of the material as well as the credits,

- Q:What is the maximum height that can be achieved with steel props?

- The maximum height that can be achieved with steel props varies depending on factors such as the specific design and load capacity of the props, as well as the conditions of the construction site. However, steel props are commonly used to support formwork and temporary structures at heights ranging from a few meters to several stories tall.

- Q:Are steel props adjustable in both height and angle?

- No, steel props are typically adjustable in height but not in angle.

- Q:Can steel props be used for supporting temporary fences or barriers?

- Yes, steel props can be used for supporting temporary fences or barriers. Steel props are typically used to support structures during construction or renovation projects, but they can also be employed to provide stability and support to temporary fences and barriers. Steel props are sturdy and durable, making them ideal for ensuring the stability and security of temporary fencing systems. They can be easily adjusted to the desired height and can withstand external forces such as wind or accidental impact. Additionally, steel props can be quickly installed and removed, making them a convenient solution for temporary fencing needs. Overall, using steel props for supporting temporary fences or barriers is a reliable and efficient way to ensure the safety and stability of the fencing system.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Climbing Formwork- Formwork- Cantilever

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords