Civil Engineering Material Geonet with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product

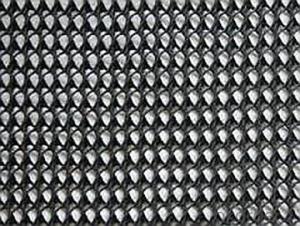

Material:

HDPE

Weight:

730gsm

Width:

2m

Length:

50m

HDPE geonet

The introduction and application of the geonet:

It is made of high-density polyethylene (HDPE) and the ultravioresistant agent with the property of aging resistance and erosion resistance.

Using the geo-net on the roadbed of the roadway and railway can distribute the load effectively, improve the loading capacity and the stability of the roadway, and prolong its service life.

Spreading the geo-net in the dyke protection in the reservoir and the river can protect it from the landslide.And with the features of good flexibility and strong erosion resistance, using it in the coast engineering can amortize the concussion and the erosion of the surf

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

4.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

5.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

6.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

7.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What is the function of geosynthetic drainage materials in road shoulder construction?

- The function of geosynthetic drainage materials in road shoulder construction is to provide effective water drainage and prevent water accumulation, which can cause damage to the road structure. These materials help to channel water away from the road shoulder, reducing the risk of erosion and improving overall road stability and longevity.

- Q:What are the specific applications of geogrid-reinforced walls in bridge abutment construction?

- The specific applications of geogrid-reinforced walls in bridge abutment construction include providing stability and support to the abutment, preventing soil erosion, reducing lateral pressure on the abutment, and increasing the overall load-bearing capacity of the structure. Geogrids are used to reinforce the soil behind the retaining wall, improving its strength and preventing movement or failure. This technology is particularly beneficial in areas with challenging soil conditions, steep slopes, or limited space, where traditional retaining wall systems may not be feasible.

- Q:Can earthwork products be used in beach nourishment projects?

- Yes, earthwork products can be used in beach nourishment projects. These products, such as sand, gravel, or fill material, can be transported and placed on beaches to replenish eroded areas, restore coastal habitats, and protect against erosion and storm damage.

- Q:What are the main features of gypsum for civil engineering materials?

- Gypsum slurry in the initial hardening will produce micro-expansion. The nature of this gypsum product surface is smooth, delicate, accurate size, full shape, good decorative.

- Q:Can geomembranes be used for floating covers in reservoirs?

- Yes, geomembranes can be used for floating covers in reservoirs. Their impermeable nature and resistance to UV rays make them an effective choice for preventing evaporation and contamination of the water in the reservoir. Additionally, the flexibility of geomembranes allows them to conform to the shape of the reservoir and provide a secure cover.

- Q:How do earthwork products contribute to carbon sequestration?

- Earthwork products, such as biochar and compost, contribute to carbon sequestration by acting as carbon sinks. When these products are added to soil, they enhance its ability to capture and store carbon dioxide from the atmosphere. Biochar, for instance, is a highly porous material that helps retain carbon in the soil for hundreds of years. Similarly, compost increases soil organic matter, improving its carbon storage capacity. By using earthwork products, we can enhance carbon sequestration in soils, mitigating climate change and promoting sustainable land management practices.

- Q:The Importance of Civil Engineering Materials in Engineering Construction

- The scope of the problem is a bit wide, the most important thing is a direct impact on the quality of the project

- Q:How can geocomposites be used in subsurface drainage systems?

- Geocomposites can be used in subsurface drainage systems to improve their effectiveness and efficiency. They are typically placed in the soil to provide a pathway for water to flow through, while also preventing the ingress of soil particles. This helps to reduce clogging and maintain the long-term performance of the drainage system. Geocomposites can also enhance the filtration and separation properties of the drainage system, ensuring that only clean water passes through while retaining the soil in place. Overall, geocomposites play a crucial role in optimizing the functionality and durability of subsurface drainage systems.

- Q:What are the advantages of using geosynthetic materials in road embankment construction?

- There are several advantages of using geosynthetic materials in road embankment construction. Firstly, these materials provide increased stability and reinforcement to the overall structure, reducing the risk of settlement and failure. Secondly, geosynthetics help in distributing the load more evenly, reducing stress on the underlying soil and improving long-term performance. Additionally, they offer excellent drainage properties, preventing water accumulation and enhancing the durability of the embankment. Moreover, geosynthetics are cost-effective, as they reduce the need for traditional construction materials and can be installed quickly, saving time and labor costs. Overall, the use of geosynthetic materials in road embankment construction results in improved strength, longevity, and cost-efficiency.

- Q:Can earthwork products be used for rainwater harvesting?

- Yes, earthwork products can indeed be used for rainwater harvesting. These products, such as trenches, berms, and swales, can be strategically designed and installed to help capture and channel rainwater into storage systems such as rain barrels, cisterns, or underground tanks. By using earthwork techniques, rainwater can be effectively collected and stored for later use, reducing water consumption and providing a sustainable source of water.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Civil Engineering Material Geonet with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products