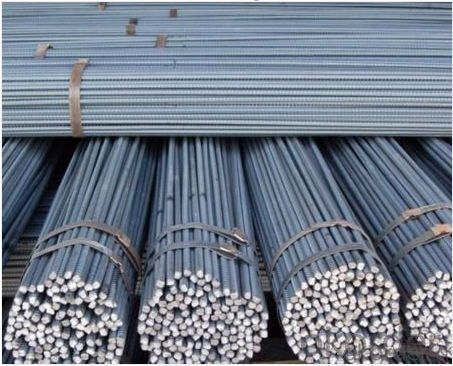

Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

OKorder is offering Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy:

Standard | GB | HRB335, HRB400, HRB500 | |

UK | G460B, B500A, B500B,B500C | ||

USA | GR40, GR60 | ||

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | China mainland | ||

Application | building,construction,road,bridge etc | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) |

6 | 28.27 | 0.222 |

8 | 50.27 | 0.395 |

10 | 78.54 | 0.617 |

12 | 113.1 | 0.888 |

14 | 153.9 | 1.21 |

16 | 201.1 | 1.58 |

18 | 254.5 | 2.00 |

20 | 314.2 | 2.47 |

22 | 380.1 | 2.98 |

25 | 490.9 | 3.85 |

28 | 615.8 | 4.83 |

32 | 804.2 | 6.31 |

36 | 1018 | 7.99 |

40 | 1257 | 9.87 |

50 | 1964 | 15.42 |

Usage and Applications of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in Coil

Produce Line of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:What are the international standards for steel rebars?

- Various organizations and bodies, such as the International Organization for Standardization (ISO), the American Society for Testing and Materials (ASTM), and the European Committee for Standardization (CEN), set the international standards for steel rebars. ISO establishes standards for steel rebars through ISO 15630, which covers both hot-rolled and cold-worked rebars. This standard outlines the requirements for the chemical composition, mechanical properties, dimensions, and tolerances of rebars used in reinforced concrete structures. ASTM has developed multiple standards for steel rebars, such as ASTM A615/A615M and ASTM A706/A706M. ASTM A615/A615M focuses on deformed and plain carbon-steel rebars for concrete reinforcement, specifying the chemical composition, mechanical properties, dimensions, and marking requirements. On the other hand, ASTM A706/A706M concentrates on low-alloy steel rebars with improved weldability, suitable for concrete structures that require welding. In Europe, CEN has established the primary standard for steel rebars as the Eurocode 2 (EN 1992-1-1). This code provides design rules for the structural use of concrete and includes guidelines for the selection and utilization of rebars. Additionally, CEN has also developed EN 10080, which specifies the requirements for steel rebars used in concrete reinforcement, covering chemical composition, mechanical properties, dimensions, and tolerances. These international standards guarantee the quality and consistency of steel rebars utilized in construction projects worldwide. Complying with these standards helps ensure the safety and reliability of reinforced concrete structures by providing guidelines for material properties, manufacturing processes, and quality control measures.

- Q:How are steel rebars measured and labeled?

- Steel rebars are measured and labeled based on their diameter, length, and grade. The diameter is typically measured in millimeters, and rebars can range from 6mm to 50mm in diameter. The length is usually measured in meters or feet, and rebars come in standard lengths such as 6m, 9m, or 12m. The grade refers to the strength and quality of the rebar and is labeled using a number system, such as Grade 40 or Grade 60. Additionally, rebars may also be labeled with relevant certification or marking to ensure compliance with industry standards.

- Q:Can steel rebars be used in structures with high moisture content in the environment?

- Steel rebars can be used in structures with high moisture content in the environment, but certain precautions need to be taken to prevent corrosion. Moisture can accelerate the corrosion process of steel, leading to structural integrity issues over time. To mitigate this risk, several measures can be implemented. Firstly, the use of corrosion-resistant steel rebars, such as stainless steel rebars, can be considered. These rebars are specifically designed to resist corrosion in high-moisture environments, making them suitable for structures exposed to moisture. Secondly, proper concrete cover thickness should be maintained to protect the rebars from direct contact with moisture. Adequate concrete cover acts as a barrier, preventing moisture from reaching the steel surface and reducing the risk of corrosion. Additionally, the use of waterproofing materials and coatings can be beneficial in preventing moisture ingress into the structure. These materials create a protective layer on the surface of the concrete, preventing water penetration and reducing the likelihood of corrosion. Regular inspection and maintenance are crucial for structures in high-moisture environments. Periodic inspections can help detect any signs of corrosion or damage early on, allowing for timely repairs or preventive measures. In conclusion, while steel rebars can be used in structures with high moisture content, it is important to implement appropriate measures to prevent corrosion. Using corrosion-resistant rebars, maintaining proper concrete cover, and applying waterproofing materials can significantly enhance the durability and longevity of structures in such environments.

- Q:What is the process of joining steel rebars together?

- Rebar splicing or rebar connection is a common practice in reinforcing concrete structures to ensure their strength and integrity. Joining steel rebars can be achieved through various methods, each with its own advantages and suitability based on project requirements. Here are some frequently used techniques: 1. Lap Splicing: This traditional and widely adopted method involves overlapping two rebars and securing them together using wire or steel tie bars. The length of the overlap is typically determined by engineering codes and standards. 2. Mechanical Splicing: A more reliable and efficient option, mechanical splicing employs specially designed couplers or connectors to join rebars. These couplers, often threaded or tapered, allow the rebars to be screwed or wedged into the connector. 3. Welding: In certain situations, rebars can be joined through welding. This technique entails heating the rebars to their melting point and fusing them together using an electric arc. Welded splices are commonly used in large-scale construction projects that require high strength and durability. 4. Compression Splicing: Compression splicing involves using compression fittings or sleeves to join rebars. The rebars are inserted into the sleeves, and a hydraulic press is utilized to compress the fitting, creating a strong connection. Compression splicing is particularly advantageous when dealing with rebars of different sizes or in areas with limited space for lap splicing. Determining the appropriate method for joining steel rebars relies on factors such as structural design, load requirements, and construction constraints. It is crucial to consult with structural engineers and adhere to local building codes and regulations to ensure the proper and safe execution of the rebar splicing process.

- Q:What are the international standards for steel rebars?

- The international standards for steel rebars are defined by the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards encompass various factors such as the composition, mechanical properties, dimensions, and tolerances of steel rebars, ensuring their quality and performance in construction projects worldwide.

- Q:Can steel rebars be used in bridge rehabilitation projects?

- Yes, steel rebars can be used in bridge rehabilitation projects. Steel rebars are commonly used in the construction and rehabilitation of bridges due to their high strength and durability. They provide reinforcement to the concrete structures, enhancing their load-bearing capacity and extending their lifespan. Additionally, steel rebars are easy to install and effectively resist corrosion, making them suitable for use in bridge rehabilitation projects.

- Q:How do steel rebars contribute to the crack control in slabs and walls?

- Steel rebars contribute to crack control in slabs and walls through their ability to resist tensile forces. When concrete slabs and walls experience loads, such as the weight of the structure or external forces, they may develop tensile stresses. Concrete is strong in compression but weak in tension, making it prone to cracking under tensile forces. Steel rebars are embedded within the concrete to counteract these tensile stresses. By absorbing and distributing the tensile forces, rebars help to prevent crack formation and control their propagation. The rebars act as reinforcement, increasing the overall tensile strength of the concrete. The presence of steel rebars in slabs and walls helps to limit the width and length of cracks that may occur by providing resistance against the tensile stresses. This crack control is crucial for maintaining the structural integrity and durability of the concrete elements. Furthermore, steel rebars can also contribute to crack control by improving the overall ductility of the structure. Ductility refers to the ability of a material to deform under load without fracturing. By enhancing the ductility of the concrete, the rebars allow the structure to absorb energy and deform in a controlled manner, reducing the likelihood of sudden failure or catastrophic collapse. In summary, steel rebars play a vital role in crack control in slabs and walls by increasing the tensile strength of concrete, limiting crack width and length, and improving overall structural ductility. Their presence ensures the long-term durability and safety of these concrete elements.

- Q:What is the average weight of a steel rebar?

- The average weight of a steel rebar can vary depending on its size and length. Steel rebars are typically sold in lengths of 20 feet and come in various diameters ranging from 3/8 inch to 1 1/4 inch. To calculate the average weight, we need to consider the density of steel, which is approximately 0.2836 pounds per cubic inch. The weight of a steel rebar can be determined by multiplying its volume (pi times the square of the diameter divided by 4, multiplied by the length) by the density of steel. For example, let's take a 1/2 inch diameter rebar with a length of 20 feet. The calculation would be as follows: 1. Convert the diameter to inches: 1/2 inch = 0.5 inches 2. Calculate the volume: (pi * 0.5^2) / 4 = 0.19635 cubic inches 3. Convert the length to inches: 20 feet = 240 inches 4. Multiply the volume by the length: 0.19635 cubic inches * 240 inches = 47.04 cubic inches 5. Multiply the volume by the density of steel: 47.04 cubic inches * 0.2836 pounds per cubic inch = 13.34 pounds Therefore, the average weight of a 1/2 inch diameter steel rebar with a length of 20 feet is approximately 13.34 pounds.

- Q:How do steel rebars contribute to the crack control in slabs and walls?

- The resistive properties of steel rebars contribute significantly to crack control in slabs and walls. When loads are applied to concrete slabs and walls, such as the weight of the structure or external forces, they can develop tensile stresses. However, concrete is strong in compression but weak in tension, which makes it susceptible to cracking under tensile forces. To counteract these tensile stresses, steel rebars are embedded within the concrete. The rebars absorb and distribute the tensile forces, preventing crack formation and controlling their propagation. Essentially, the rebars act as reinforcement, enhancing the overall tensile strength of the concrete. The presence of steel rebars in slabs and walls has the additional benefit of limiting the width and length of cracks that may occur. This is achieved by providing resistance against the tensile stresses. This crack control is of utmost importance in maintaining the structural integrity and durability of the concrete elements. Moreover, steel rebars also contribute to crack control by enhancing the overall ductility of the structure. Ductility refers to the ability of a material to deform under load without fracturing. By improving the ductility of the concrete, the rebars enable the structure to absorb energy and deform in a controlled manner. This reduces the likelihood of sudden failure or catastrophic collapse. In conclusion, steel rebars play a crucial role in crack control in slabs and walls. They increase the tensile strength of concrete, limit crack width and length, and improve overall structural ductility. Their presence ensures the long-term durability and safety of these concrete elements.

- Q:Can steel rebars be used in the construction of offshore oil platforms?

- Indeed, the inclusion of steel rebars is deemed feasible for the construction of offshore oil platforms. In construction practices, steel rebars are commonly employed to fortify concrete structures, thereby enhancing their strength and durability. In the context of offshore oil platforms, the use of steel rebars serves to fortify the concrete foundations and structures of the platform, facilitating its resistance against the adverse environmental conditions as well as the weight of the equipment and infrastructure situated on the platform. These steel rebars are engineered to withstand corrosion and are typically coated with epoxy or other protective coatings to prevent rusting within the corrosive marine environment. Additionally, steel rebars can be specifically tailored to meet the precise requirements of the offshore oil platform, thereby ensuring that they deliver the essential strength and stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords