Ceramic Knife Peeler Set with Gift Box Chef Knife with Peeler

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Ceramic Knife

Ceramic knife known as "noble knife", as a modern high-tech products, with the advantages of traditional metal knives unmatched; using high-tech nano-zirconia materials, so ceramic knife called "zirconium gem knife", its elegance and luxury evident.

Application of Ceramic Knife

1. The ceramic knife can prevent itself from cautery of serious of acids and bases organic

matter,rustiness,changing colors and diffluence of metal ion,so it would be more healthy

and environmentally-friendly.

2. It`s easy to clean and can keep the primitive colors and original sapor of food. Besides,

it would not reat with the food that it seldom leads to microorganism breeding.

3. The knife is nonmagnetic completely.And it is made of compactd material so that it is

with no holes.

Advantage of Ceramic Knife

1.Lasting sharp,Never need to whet knife

2.Food oxidation resistance, retain freshness

3.Non rusty,no chemical reaction when contact with food

4.Healthy and environmental protection

5.Quality life choice

6.Elegant appearance

Packing of Ceramic Knife

1.Flocking plastic in Gift box

2.EVA White box

3.(Also as your request. )

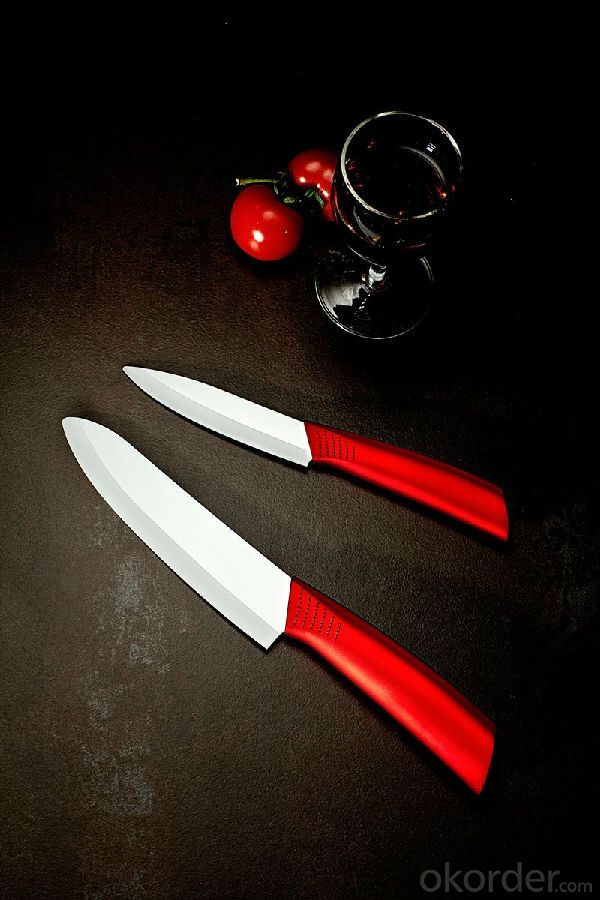

Pictures of Ceramic Knife

Specification of Ceramic Knife

| Composition | Wt% | ZrO2+Y2O3%≥99.5 |

| Specific density | g/cm3 | >6.0 |

| Hardness(HV) | HRA | >87 |

Thermal expansion Coefficient(20-400) | (10-6/K) | 9.6(20~400) |

| Elastic modulis | GPa | 200~250 |

| Fracture toughness | MPa.m1/2 | 7-10 |

| Bending strength | MPa | >1150 |

| Grain size | μm | <0.6< td=""> |

| Thermal conductivity | W/(m .k) | 2.5 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What is the sintering and electroplating tools ah? What is the difference?

- Sintering definition:Macro definition: at high temperature (not higher than the melting point), other key green ceramic particles, grain growth, voids (pores) and grain boundary gradually reduced by the material transfer, the total volume shrinkage, density increases, and finally become a dense microstructure of polycrystalline sintered body, this phenomenon is called sintering.Microscopic definition: solid molecular (or atomic) are attracted to each other, by heating the particles to obtain enough energy for migration, make the powder particles bond, produce strength and lead to the densification and recrystallization process called sintering.

- Q:Excuse me, master, difference, white steel cutter and tungsten steel knives advantages, what are the disadvantages?

- 1 tungsten steel knives can withstand the power, used for machining hard materials, processing materials after heat treatment, the service life is long; but the price is more expensive.2 high-speed steel tool steel is a plain white, like SKD11, with more in general machining, cutting force no tungsten steel cutting tool price is relatively cheap.

- Q:CNC machine tools and cutting tools for the performance of the material requirements?

- There is no special needs, due to the general use of CNC machine tool business efficiency and accuracy requirements are relatively high, so we should try to choose some of the more high-end tools.

- Q:What are the features of the CBN tool?

- The proper customization of the specified process includes the rigidity of the machine tool and fixture, the sharpening of the blade is large enough to prevent the micro exfoliation, and the base of the cutter is a kind of material with high CBN content. High CBN levels are necessary for these specified processes, since they have high thermal conductivity and toughness required for high speed machining under the condition of heavy cutting edges, as well as for severe intermittent cutting. These properties make the tool material this material grade is used as rough machining of hardened steel and gray cast iron.

- Q:Please explain the reasons, thank you.

- This is actually a lot, your cutting parameter is reasonable, whether there is sufficient cooling, the tool material is with workpiece materials, precision machine tools, precision knife handle.

- Q:YG813 carbide tools can be intermittent turning stainless steel? How much is the cutting speed?

- Good abrasion resistance, high bending strength and bond resistance. Suitable for processing high temperature alloy, stainless steel, high manganese steel and other materials

- Q:Processing about 60 degrees of material, what is good?

- The 60 degree is the hardness of the material. With a carbide cutter. Their hardness is 89~93 degrees. At 800~1000 DEG C can undertake cutting.

- Q:Want to buy a knife, you can select the steel carbon steel and high carbon steel, do not know the knife performance between big two kinds of steel making, see carbon steel knife can also be cut iron said selling knives on the site, do not know is not a bit exaggerated, but the price is a lot cheaper in carbon steel. Please master pointing

- The higher the carbon content, the higher the hardness and the worse the plasticity

- Q:How to clean the kitchen tool set

- For cutting meat, cutting the tool after the bone, you need to clean up the grease above, and then dry or dry.

- Q:What is the reference system of tool geometry?

- The reference system of cutting tool geometric angle can be divided into two categories: static reference system and working reference system.In order to ensure the smooth operation of the cutting process, to obtain a qualified processing surface, the cutting part of the tool must have a reasonable geometric shape. Tool angle is an important parameter for determining the geometry of the cutting tool.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Knife Peeler Set with Gift Box Chef Knife with Peeler

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords