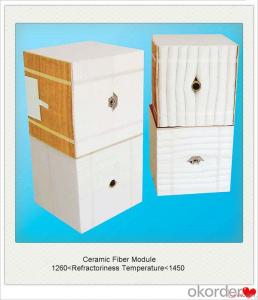

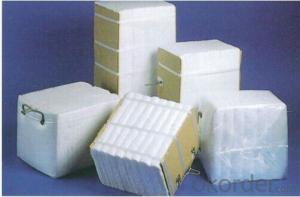

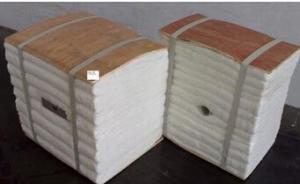

Ceramic Fiber Module 1350 HA

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Module

Our ceramicfiber module products are made of ceramic fiber blanket, which are stack foldedto form a module with folded edges exposed. Our ceramic fiber modules areavailable in different classified temperature from 1260 ℃ to 1430 ℃. Our insulatingproducts provide substantial improvement in thermal performance, using ourceramic fiber modules can save your money in energy costs and also can helpreduce your operations environmental footprint.

Features of Ceramic Fiber Module

Easy to install

Heat resistance

Light weight

Low thermalconductivity

Low heat storage

Resilient to thermalshock

High tensile strength

Application of Ceramic Fiber Module

We specialize inhigh-temperature insulation products, providing innovative heat managementsolutions and energy savings methods for a broad range of industries. Our ceramicfiber modules are mainly used in:

Petrochemical processheater

Heat treating furnace

Cement rotary kiln

Glass melting tank

Ceramic firing kiln

Backup insulation

Classification Temperature | ℃ | 1350 |

Working Temperature | ℃ | 1200 |

Color |

| WHITE |

Bulk Density | kg/m3 | 160~200 |

Thermal Conductivity (W/m.k) |

|

|

(Density 200kg/m3) | 800℃ | - |

| 1000℃ | 0.18 |

| 1200℃ | 0.26 |

Thermal Shrinkage 24hrs, | ℃ | 1300 |

(Density 200kg/m3) (%) | % | ≤3.5 |

Chemical Composition: |

|

|

Al2O3 | % | 53~55 |

Al2O3 + SiO2 | % | 99 |

Size: Length:≤600mm Width: ≤600mm Thickness: ≤600mm Typical size: 305mm*305mm*152mm/203mm/305mm (Non-standard sizes are available upon request)

| ||

Note: | ||

- Q:Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- After 2013, the hot dip galvanizing furnace is usually made of ceramic fiber modules for insulation, as follows:The appearance of new thermal insulation material breaks the inherent heat loss barrier in our country. The new type of thermal insulation material is mainly made of ceramic fiber and heat insulation cotton. It is combined with bolt, nut, carpet blanket, module and compensation blanket to achieve high heat preservation.

- Q:How to install refractory fiber?

- Dry plate is used to spray adhesive mechanical pressing low density has good elasticity and flexibility is usually used for wet insulation sealing by washing vacuum shaping mould plate of high density, hardness, mechanical processing can be generally used as fireproof heat insulation is very good Oh, you can try

- Q:Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q:What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

- Q:Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q:What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Module 1350 HA

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords