Ceramic Fiber Blanket 1260 High Pure for Heating Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

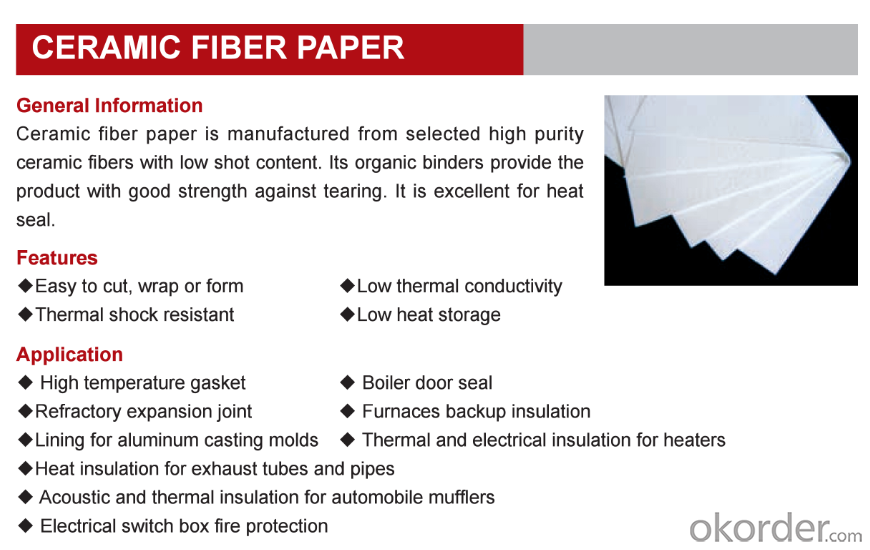

Features of ceramic fiber flexible heat refractory paper

1.light weight

2.easy to install

3.Low thermal conductivity

4.good electric insulation

5.excellent corrosion resistant

6.Free of asbesto

Application range of ceramic fiber flexible heat refractory paper

1.Industrial material for thermal insulation ,sealing and corrosion prevention.Such as high temperature thermal insulation material for industrial furnace and steel ladle, seal material for furnace expansion joints, insulation for the glass products.

2.Thermal and electrical insulation material for electric heating device. Such as industrial electrical furnace.

3.Electrical and thermal insulation material for instrument equipment and heating element, like seal the lining of the cast aluminum model.

4.Heat insulation material for auto industry, such as auto exhaust pipe.

Technical data of ceramic fiber flexible heat refractory paper

Classification Temperature(°C) | 1260 | 1450 | ||

Working Temperature(°C) | 1200 | 1400 | ||

Chemical Composition (%) | AL2O3 | 47 | 38 | |

SiO2 | 51 | 44 | ||

Fe2O3+Ti2O3 | ≤0.3 | ≤0.2 | ||

CaO+MgO | ≤0.3 | ≤0.2 | ||

Na2O+KO2 | ≤0.3 | ≤0.2 | ||

Density (kg/m3) | 180-220 | |||

Common Size | Length×Width ×thickness 60,000×610/1220×1mm 30,000×610/1220×2mm 20,000×610/1220×3mm 15,000×610/1220×4mm 12,000×610/1220×5mm 10,000×610/1220×6mm | |||

- Q:Why is there no direct relationship between thermal conductivity and conductivity of ceramics?

- The advanced production technology enables the fiber to distribute very evenly, and the paper thickness and bulk density can also be strictly controlled. Ceramic fibers have very low thermal conductivity. The thermal conductivity of ceramic fiber paper was measured by thermal flow method.

- Q:Why doesn't the insulation effect of ceramic fiber compound reflect the insulation board well?

- And although the ceramic fiber high temperature resistance, but in 1400 degrees when the use of life will be greatly reduced, and the thermal conductivity of the beginning as compound reflection insulation board, high temperature is higher than the compound reflection insulation board greatly.

- Q:What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- Ceramic fiber products (aluminum silicate fiber products) in recent years, ceramic fiber products (aluminum silicate fiber products) in the application of high temperature sintering furnace expanding, ceramic fiber products (aluminum silicate fiber products) refractory felt and blanket products, the highest use temperature up to 1649 DEG C. Ceramic fiber products (aluminum silicate fiber products) to heat insulation effect is good, easy to use, especially small heat storage characteristics, widely used in various kilns, greatly demonstrated high energy efficiency.

- Q:Can ceramic fibers be spun into fibers, please?

- Ceramic fiber itself is relatively brittle, silk is relatively short, spinnability, but after adding viscose (differential polyester glass fiber, even pulp) as the heart can be spun

- Q:What's the function of refractory ceramic fiber band?

- Refractory ceramic fibre belt is made of ceramic fiber cotton, E-glass filament, high temperature resistant stainless steel alloy wire processed by special technology, products of high strength, good flexibility, high machinability, not only has high temperature heat insulation performance, both ordinary textile flexibility.

- Q:What's the fire resistance of the ceramic fiber?

- Because of the low heat conductivity, small density and light weight of the fiber, the light steel support structure is adopted in the design and construction of the kiln, which makes the development of the ceramic kiln into the lightweight era of the kiln. The fiber has small heat storage and is suitable for quick heating and cooling firing. Flexible fibers can be processed into products with grooves or openings, and has good resistance to mechanical shock and impact ability, chemical stability is good, these advantages for the development of new kiln, and spread to the development of ceramic industry, have an important role in promoting. The ceramic fiber products are: carpet, blanket, block, a variety of products like fiber, dispersion of fiber paper and vacuum forming, the work is generally in the range of 8711427 DEG C, under special circumstances can be short-term use in the high temperature limit temperature above the.

- Q:Which insulation effect is better compared with ceramic fiber for STP insulation board?

- Solid energy saving STP insulation board, its insulation performance than traditional ceramic fiber insulation material is better than 3~4 times

- Q:How are ceramic fiber papers attached to the interior wall?

- There are two ways to apply ceramic fiber paper to the wall. The first is to buy ceramic fiber paper with single-sided adhesive tape, and the second is to paste it directly with double-sided adhesive tape. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter

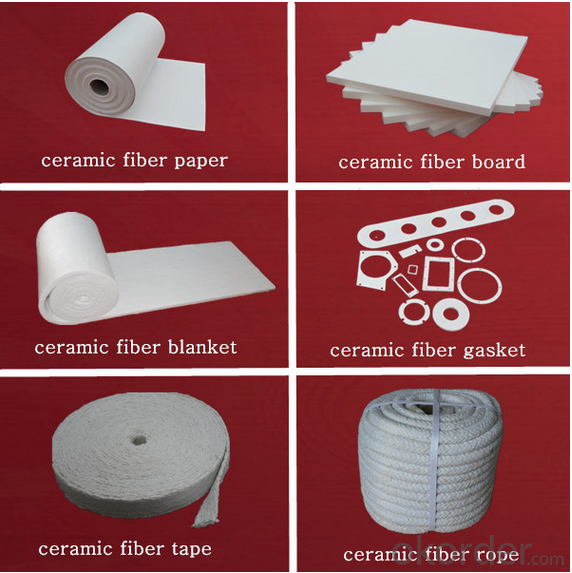

- Q:The difference between ceramic fiber cloth and ceramic fiber paper?

- Appearance。 The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.Density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.Thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.Stand upright。 Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. The ceramic fiber cloth is like the cloth used in our life. It is very soft and has no standing.Tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q:The condition of ceramic glass fiber at high temperature

- Glass and ceramic fibers are inorganic non-metallic materials, they are silicate, can be used as structural materials that emphasize mechanical properties, but also can be used as functional materials that emphasize photoacoustic magnetic properties, but the 1. general glass is amorphous substance, the fibers are formed by melting under drawing while; ceramics is a crystal structure of the fiber by solution or melt into the crystal growth out of course, can also be formed by chemical synthesis or decomposition method;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket 1260 High Pure for Heating Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords